Zhengzhou Caihua Kiln Masonry Installation Co., Ltd. was established in 1984 in the brand of CH REFRACTORIES provides the highest quality of refractories and knowledge coupled with leading source of R&D advancements. Our seasoned team provides the expertise passion and attention to detail providing our customers the value-added service they need to succeed. CH REFRACTORIES is professional manufacturer of fire bricks, Mortar, Pre-cast, Pre shape, Insulation products, Castable, Functional Products for Iron & Steel, Cement, Glass, Power & Petrochemical Industries. CH REFRACTORIES manufacturing plant is located in the Xinmi City that is rich refractory raw materials and coal storage. Unique conditions provide extremely convenient conditions for the production and development of refractories.

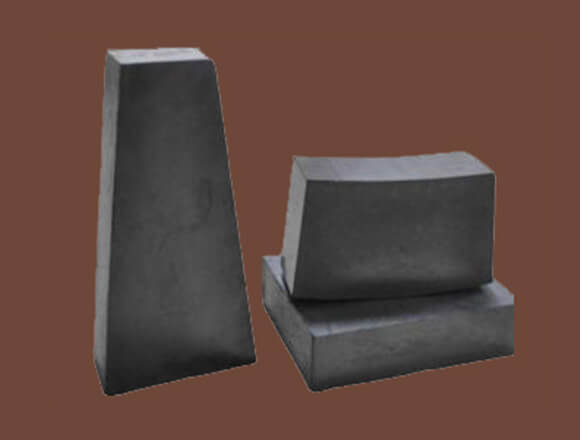

Mag carbon bricks are made of fused magnesia, high-purity magnesia and graphite, and are formed by high pressure molding and low temperature treatment. Different grades of mag carbon bricks can be selected according to different smelting conditions , service life in heats and smelting steel grades.

Learn More

The heat resistant refractory cement also well known as calcium aluminate cements, and high alumina castable refractory cement. Generally there are 4 grades of refractory cement according to Al2O3 content, A600, A700,A900 and CA-70.

Learn MoreCH REFRACTORIES has 158 middle-level technical titles and 38 senior technical titles. The company has strong technical strength and has established stable technical cooperation with Luoyang Refractory Materials Research Institute, Zhengzhou University High Temperature Research Institute, Beijing University of Science and Technology, Northeastern University, Anshan Iron and Steel College and other institutions of higher learning. It is the Beijing University of Science and Technology. Production, teaching and research bases.

CH Refractories has extensive experience in the operation of the project and will assist the client in completing the preparatory work for the project.Caihua has sufficient experience in on-site management of refractory materials, so we will communicate our experience with users to lay the foundation for future on-site management, and provide customers with the best refractory supporting advice and solutions according to the characteristics and requirements of the project. Program.

CH Refractories will dispatch 3-5 service personnel to the scene to help solve the problems on the spot. Cooperate with customers to do product classification, acceptance, storage, etc., technicians provide on-site technical services to users free of charge, and have problems to solve on-site. If the construction site conditions do not have the capacity to store a large amount of goods, our company can be managed as a temporary warehouse, and according to the construction progress, the two sides can transfer the goods at any time. The on-site service personnel will master the progress of the project and coordinate with the construction unit in time. Ensure the progress of the project.

CH Refractories will respond to the user's request for technical support as quickly as possible, and clearly complete the technical support time for the user according to the work content. Meet the needs of users and ensure the normal operation of customer equipment. Set up a 24-hour after-sales service line (company headquarters: 0371-69987777), have a full-time staff on-duty tracking service, holidays as usual, to ensure that users are on call. After receiving the notice, the province was within 24 hours, and within 72 hours of other areas, our unit personnel rushed to the scene to solve the problem.

Qinghai Dongrun Silicon Industry Co., Ltd. is mainly engaged in the production and sales of metal silicon and ferroalloys; sales of silica, coal, wood chips, coke raw materials, building materials, electromechanical equipment (except for small cars), project investment, energy conservation projects, environmental protection projects, and technology. Transformation, environmental protection and energy-saving technical services, smelting technical services. Caihua Kiln Co., Ltd. is well managed in the material construction of the 33000KV ferrosilicon electric furnace in Qinghai Dongrun Silicon Industry. The construction is meticulous and overcomes many unfavorable construction factors such as weather and environment. It has been repeatedly praised and rewarded, and has made a positive result for the smooth operation of the project. It is a construction team that can endure hardships, fight and trust.

Tianjin Tianzhongjiangtian Heavy Industry Co., Ltd. is a specialized enterprise for the production of large-scale castings and forgings and heavy-duty complete sets of equipment based on the complete restructuring and restructuring of Tianjin Heavy Machinery Factory, one of the original “China Eight Heavy Machinery”. Eight production plants, such as steel, cast steel, forging, heat treatment, machining, steel rolling and kinetic energy, and supporting oxygen stations, gas stations and physical and chemical testing centers have formed the integration of heat treatment, machining, machining, processing, refining, casting, forging, rolling and metal processing. Industry chain. In 2015-2019, the talented kiln for the Tianfeng Heavy Industry Co., Ltd.’s hot blast stove and supporting hot blast stove appeared unstable temperature, and the lining erosion was serious, and made a targeted plan. Completely solved some incurable diseases, thus ensuring efficient and stable operation of high temperature kiln. During this period, our company upgraded the desktop heating furnace of Jiangtian Heavy Industry Co., Ltd. from the design, material selection and construction of lining materials. Effective rectification opinions were successfully completed and waited until Jiangtian Heavy Industry Co., Ltd. has been well received.

Shanxi Yangmei Group Taiyuan Chemical New Material Co., Ltd. is a demonstration project for the construction of a national new energy and industrial base in Shanxi Province and the first batch of provincial-level transformation comprehensive reform benchmark projects. It is the active elimination of backward production capacity by Yangmei Group and the relocation and transformation of Taihua Group. Key projects to achieve strong coal strategic goals. The talented kiln company is organized in the construction process, strictly controls the quality and pays close attention to safety. Under the premise of ensuring safety and quality, the maintenance task was completed ahead of time, laying a solid foundation for the ignition of the 3# unit of our company. And it is possible to finish the site after the completion of the work.