Fast Drying Castable for Iron Notch is made of corundum, high quality bauxite and silicon carbide incorporated with appropriate drying agent. By firing 2 to 3 hours, the products can be put into use, and show excellent performance.

EAF tap-hole filler is developed with magnesite, forsterite and silica as the main materials according to different requirements, and shows the features of easy installation, good sintering, floating resistance, high self-open rate and good safety performance.

Checker Brick is a kind of heat-transfer medium, which is mainly used for middle-upper part of regenerative chamber in hot blast stove for thermal storage in the burning period.

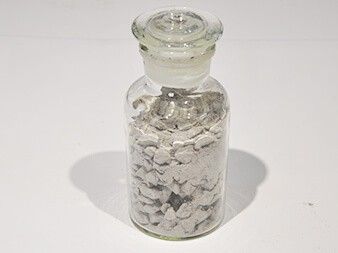

AI203-Mg0-C bricks:This series of products are made from corundum, magnesium aluminate spinel, super-grade bauxite, high quality MgO and graphite as main raw materials and phenolic resin as binder.

Base on high quality magnesite and graphite as main raw materials, low carbon MgO-C bricks are produced via pressing and low temperature pre-baking and mainly used in slag zone of ladle lined with low carbon or carbon-free refractories for low and ultra-low steel production.

Castables for Iron Runner use dense corundum, brown corundum, high-quality rock, and high-quality SiC as the main raw materials. Castables for Iron Runner is made of low-cement and ultra-low-cement castable technology.