Refractory castable for rotary kiln is suitable for calcination and roasting of cement, limestone,magnesia, ilmenite and non-ferrous metal ore. Castable for rotary kiln has the advantages of strong acid and alkali corrosion resistance and good wear resistance and long service life.

This product has high thermal strength, strong wear resistance, excellent corrosion resistance and high temperature volume stability, effectively extending the service life of CFGboilers. Can be used for the wear lining of various CFB boilers.

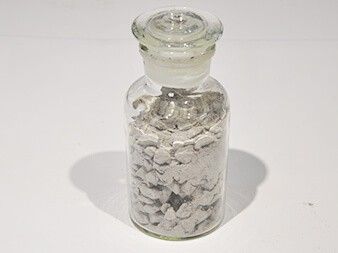

Wear-resistant plastic, which is made of special grade alumina, mullite, corundum, siliconcarbide as aggregate and matrix material, mixed by adding binder, additive and plasticizer.

The acid-resistant refractory bricks produced by our company adopt high-grade refractory aggregates, powders, additives, etc. After reasonable grading and high-temperature firing, they can fully meet the acid and high temperature resistance of furnace lining refractories under various acid regeneration process conditions.

Castable for carbon calcined rotary kiln has the advantages of high strength, high wear resistance, anti-flaking and anti-scouring. Castable for carbon calcined rotary kiln is suitable for rotary kiln kiln mouth, pre-tropical zone, calcination zone, cooling machine, feed nozzle and other parts.

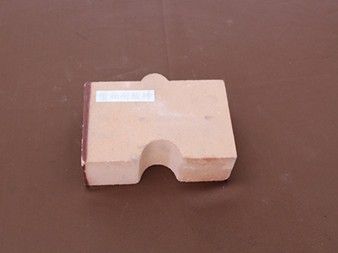

Composite spinel firebrick is a product obtained by high-pressure molding and high-temperature sintering using high-purity magnesia andmagnesia-chromium composite spinel as main raw materials.