The Composite Brick Technology

The composite brick technology is a general design of refractory masonry for high-temperature kiln protection or thermal equipment, and the complex space geometry formed by the intersection of simple geometry is disintegrated into dozens or hundreds of refractory bricks with complex shapes. These complex-shaped refractory bricks are interlocked with each other and reasonably transmit stress to form a solid and stable masonry.

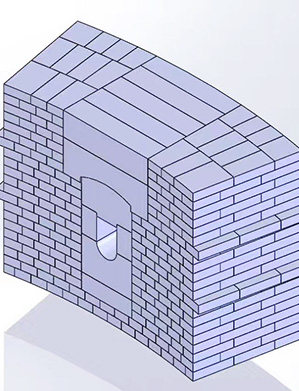

3D Model

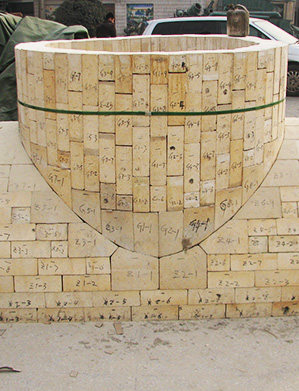

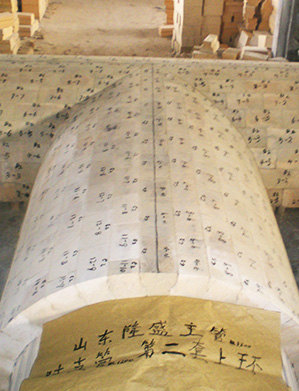

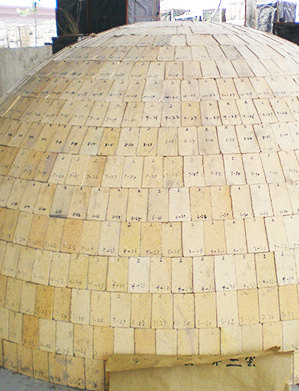

Pre-masonry in Actual Production

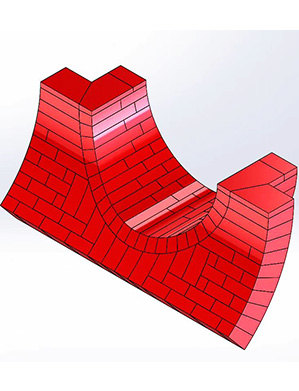

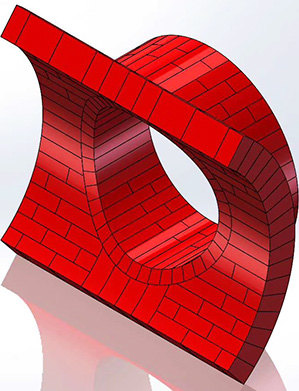

3D Model

Pre-masonry in Actual Production

3D Model

Composite Bricks At Three Forks

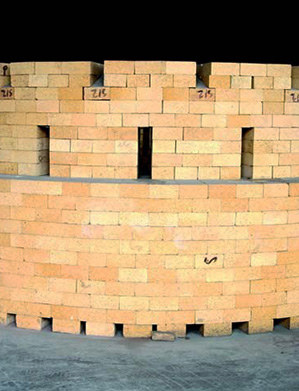

BF Tuyere Composite Brick

Combination Brick of Hot Blast Stove

Ball-top Composite Brick

Composite Brick

Composite Brick

Composite Brick

Case Implementation Process

-

01

Problem Analysis

User communication is accurate. Problems occur in the high temperature kiln

-

02

Pre-Processing

Solutions for the problem

-

03

3D Modeling Analysis

Improvement and continuous rectification to find the best solution

-

04

Iteration Calculation

Communicate with customers to show the design effect , as well as problem solving and determining the material.

-

05

Post-Processing

Result analysis

-

06

Production

Arrange production according to the drawings

Based on the modeling of Solidworks, the flow simulation was used for numerical simulation, and the results were used to test the performance of the designed kiln. In short, in the design process of industrial furnaces and kiln and other thermal equipment, the design method, design tools, and the effective and optimized combination of calculation methods can design the user with reasonable structure, convenient construction, convenient management and reliable data. Expressing accurate design and construction drawings and giving accurate and detailed bills of materials, the company has brought complete and high-quality technical services to customers while improving the company’s efficiency.