-

What are the main physical and chemical properties of continuous casting powder?

The chemical composition of each grade of protective slag should be analyzed. The content of each oxide should be within the specified range. This is the minimum index.

16-11Learn More

-

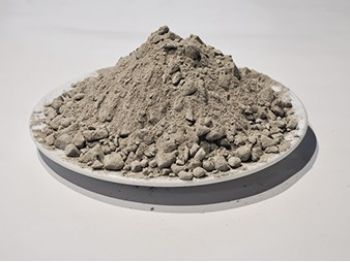

Technical characteristics of refractory castables

Refractory castable is a kind of amorphous refractory which is widely produced and used at present. Mainly used to build a variety of heating furnace lining and other integral structures. Certain quality varieties can also be used in smelting furnaces.

13-11Learn More

-

Classification of Taphole clay – water taphole clay

With the development of large-scale blast furnace, smelting, high wind pressure and low furnace times, the quality of the mortar is more and more high, and from the point of view of environmental protection, the requirements of the mortar in the iron hole when no smoke, iron hole week gas without benzene.

13-11Learn More

-

Function and performance of blast furnace taphole clay

Small blast furnaces are generally provided with an iron outlet and 2 ~ 3 slag outlet, large and medium-sized blast furnaces have 2 ~ 4 iron outlet and 1 ~ 3 slag outlet. The taphole clay used to plug the iron opening is squeezed in by a mud gun, so it is also called gun mud.

13-11Learn More

-

Refractory material scheme for mineral thermal reduction furnace

Refractory materials for mineral thermal reduction furnace include three parts: refractory materials for furnace top, refractory materials for furnace wall and refractory materials for molten pool (furnace slope and furnace bottom). Refractories in different parts are in different working states during ferroalloy smelting.

12-11Learn More