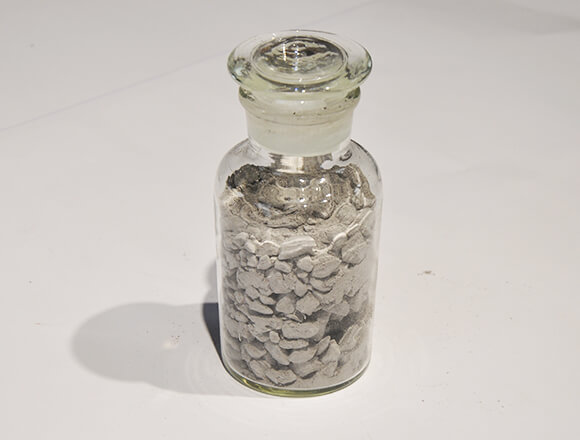

Al2O3-SiC Castable for Metal Mixer is developed with high quality bauxite, corundum and SiC as the main raw materials, and bonded by low cement or ultra-low cement.

Al2O3-SiC Castable for Metal Mixer is developed with high quality bauxite, corundum and SiC as the main raw materials, and bonded by low cement or ultra-low cement. Al2O3-SiC Castable for Metal Mixer is characterized with good volume stability, excellent slag erosion resistance and thermal shock resistance, and gain good performance.

|

Product code |

CH-HTJ-L70 |

CH-HTJ-L65 |

CH-HTJ-L55 |

|

Al2O3/% |

≥70 |

≥65 |

≥55 |

|

SIC% |

≥12 |

≥12 |

≥10 |

|

Bulk density/g.cm3 |

≥2.6 |

≥2.50 |

≥2.4 |

|

Cold crushing strength/Mpa

|

≥30(110℃,24h) |

≥25(110℃,24h) |

≥40(110℃,24h) |

|

≥60(10400℃,3h) |

≥55(1400℃,3h) |

≥60(1400℃,3h) |

|

|

Permanent linear change/% |

±0.4(1400℃,3h) |

±0.5(1400℃,3h) |

±0.6(1400℃,3h) |

|

Application |

Working lining at side wall and bottom |

Top and tapping hole |

|

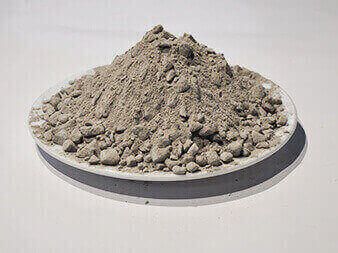

Castable for carbon calcined rotary kiln has the advantages of high strength, high wear resistance, anti-flaking and anti-scouring. Castable for carbon calcined rotary kiln is suitable for rotary kiln kiln mouth, pre-tropical zone, calcination zone, cooling machine, feed nozzle and other parts.

The appropriative fireproof castable for kiln door is a high-performance castable developed according to the working conditions of the rotary kiln. Appropriative refractory castable for kiln door has good performance of volume stability, high strength, good wear resistance, thermal shock resistance, corrosion resistance,anti-stripping when using.

Using high quality magnesia as the main materials, by adding compound binding additives, this series of gunning mixes for EAF feature high adhesive strength, low rebound rate, good sintering, good erosion resistance, and can be used as cold or hot repair materials at slag line and side wall.

If you need our products please write down any questions, we will reply as soon as possible.