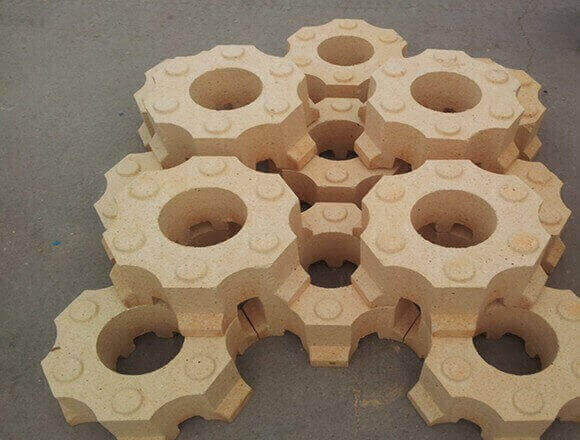

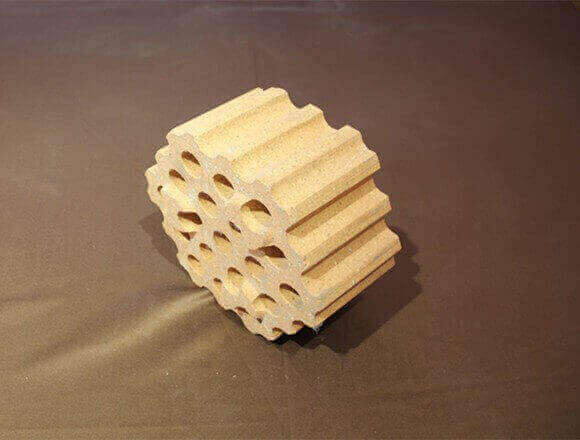

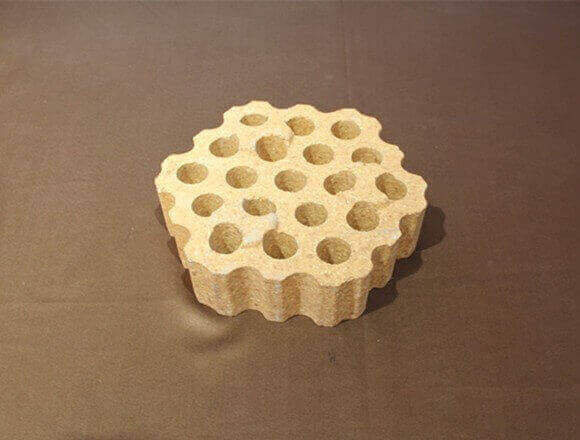

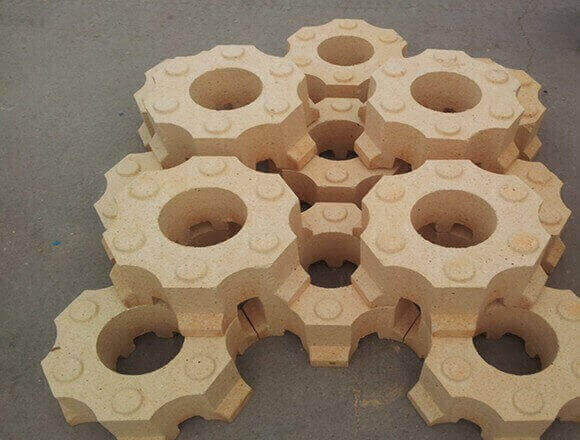

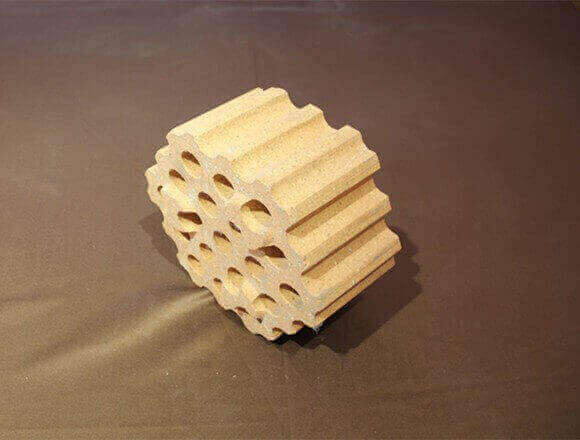

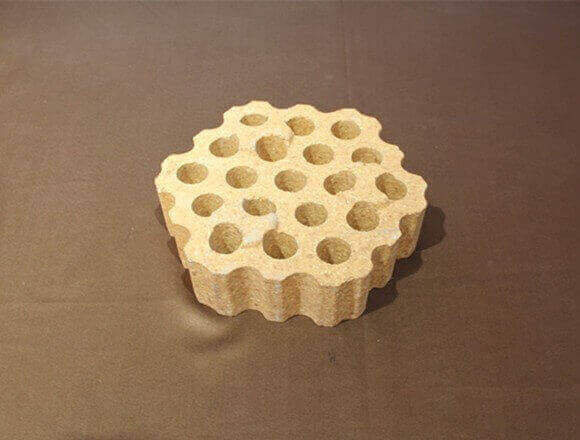

Checker Brick is a kind of heat-transfer medium, which is mainly used for middle-upper part of regenerative chamber in hot blast stove for thermal storage in the burning period.

Checker Brick is a kind of heat-transfer medium, which is mainly used for middle-upper part of regenerative chamber in hot blast stove for thermal storage in the burning period. Checker Bricks play the extremely important function in the process of heating cool wind up to hot wind through convective heat exchange and radiation heat transfer in the blast period. Checker Brick is widely used in iron smelting industry as a kind of heat-carrier with excellent thermal engineering performance of strong heat exchange ability, large thermal storage area, smooth ventilation and low resistance. Checker Bricks are mainly used in the hot blast stove. When the hot wind is lower than 900℃, generally adopt fireclay bricks. When the wind temperature is higher than 900℃, adopt high alumina refractory bricks, mullite brick, sillimanite brick and silica refractory bricks and etc.

Advantages of Checker Brick:

●Good volume stability

●High bulk density

●Low apparent porosity

●Good high-temperature loading creep property

Applications of Checker Brick:

●Blast furnace

●Fame furnace

●Regenerative chamber in the hot blast stove

|

Item |

Unit |

HLG |

LLG |

|

Al2O3 |

% |

≥50 |

≥45 |

|

Fe2O3 |

% |

≤1.6 |

≤1.6 |

|

Refractoriness |

℃ |

≥1600 |

≥1600 |

|

Apparent Porosity |

% |

≤22 |

≤24 |

|

Bulk Density |

g/cm3 |

≥2.45 |

≥2.35 |

|

Cold Crushing Strength |

MPa |

≥80 |

≥60 |

|

Refractoriness Under Load (0.2MPa) |

℃ |

≥1500 |

≥1400 |

|

Permanent Linear Change (1500℃*2h) |

% |

±0.2 |

±0.2 |

Zircon refractory ramming material is made of high-quality zircon sand aggregate, powder, aluminum phosphate as binder and admixture, and has the best ratio of thermal conductivity and thermal shock resistance.

Precast blocks for EAF roof is made by steel fibre reinforced ultra-low cement castables with corundum, spinel and mullite as the main materials, and characterized with high strength, good thermal shock resistance, good erosion resistance and long service life.

Various types of ventilated bricks(ladle Porous plug) such as through-hole type, directional slit type, directional labyrinth type, internal integral type and external split type can be designed and manufactured according to user requirements, and the matching ventilation block locking mechanism can be designed according to user requirements.

If you need our products please write down any questions, we will reply as soon as possible.