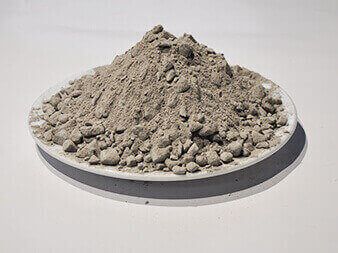

Light weight fire clay brick is made of local top grade fireclay materials under the high temperature according to the lastest national standard. The temperature in the 1200-1400 ℃. Ingredients are mixed with water made of plastic material or mud, mud with extrusion or pouring shape, 1250-1350 ℃ after dry burning oxidation atmosphere.

Light weight fire clay brick is made of local top grade fireclay materials under the high temperature according to the lastest national standard. The temperature in the 1200-1400 ℃. Ingredients are mixed with water made of plastic material or mud, mud with extrusion or pouring shape, 1250-1350 ℃ after dry burning oxidation atmosphere. The volume density of commonly used insulated clay brick is 0.75-1.2 g/cm3. There are insulating clay bricks, high alumina insulation brick and mullite jm insulating bricks for insulation layer, which are suitable for different high temperature. Just please inform us your required bricks working temperature, we can provide you the most economical suggestions to you.

Because heat insulating bricks with smaller bulk density whose strength is not as strong as heavy weight fire bricks, when delivering, CH Refractories will package insulating firebricks with special packages to protect insulating clay bricks from damage.

Applications of Clay Insulation Brick:

●Thermal equipment and furnace lining

● Insulation of masonry industrial furnaces

Advantages of CH series Clay Insulation Brick:

●High compressive strength

●Good energy saving performance

●Widely application with different bulk density

●Very economical insulation brick for high temperature insulating layer

●Customerize mould according to different size requirements for free.Free mould charge for complicated shaped bricks

●the clay insulation brick can be made into diatomite brick,high compress strength,good insulation performance,low thermal conductivity.

|

Brands |

Clay Insulation Brick |

|||

|

/ |

CH-NG-0.5 |

CH-NG-0.6 |

CH-NG-0.8 |

CH-NG-1.0 |

|

BD g/cm3 ≥ |

0.5 |

0.6 |

0.8 |

1 |

|

CCS/Mpa ≥ |

1.5 |

2 |

2.5 |

3.4 |

|

The reheating line changes by no more than 2% of the test temperature/℃≤ |

1250 |

1300 |

1350 |

1350 |

|

Thermal conductivity average temperature 350±25℃(W/m.k) |

0.18 |

0.25 |

0.35 |

0.5 |

|

0.1MpaRefractoriness under load (RUL)/℃ ≥ |

1160 |

1250 |

1280 |

1300 |

|

Fe2O3% |

2.5 |

2.5 |

2 |

2 |

|

Maximum use temperature/℃ |

1150 |

1200 |

1280 |

1300 |

High alumina castable is a kind of refractory castable which uses high alumina raw materials as aggregates and the powder and then be added with binding agent. High aluminum castable refractories has high mechanical strength, good thermal shock resistance, good corrosion resistance.

The high strength castable refractory steel fiber reinforced wear-resistant castable is prepared by adding special grade aluminum bauxite clinker or corundum as aggregate and powder, adding binder, admixture and heat-resistant stainless steel fiber.

Refractory clay mortar is referred to as soft clay. It isair setting refractory mortar, a refractory clay with plasticity. The constituent minerals of high temperature mortar are mainly kaolinite and hydromica. Generally, refractory mortar mix contains Al2O3 ≥ 22% ~ 30%, SiO 2 ≥ 42% ~73%, and the refractoriness is 1580 ~ 1670 °C.

If you need our products please write down any questions, we will reply as soon as possible.