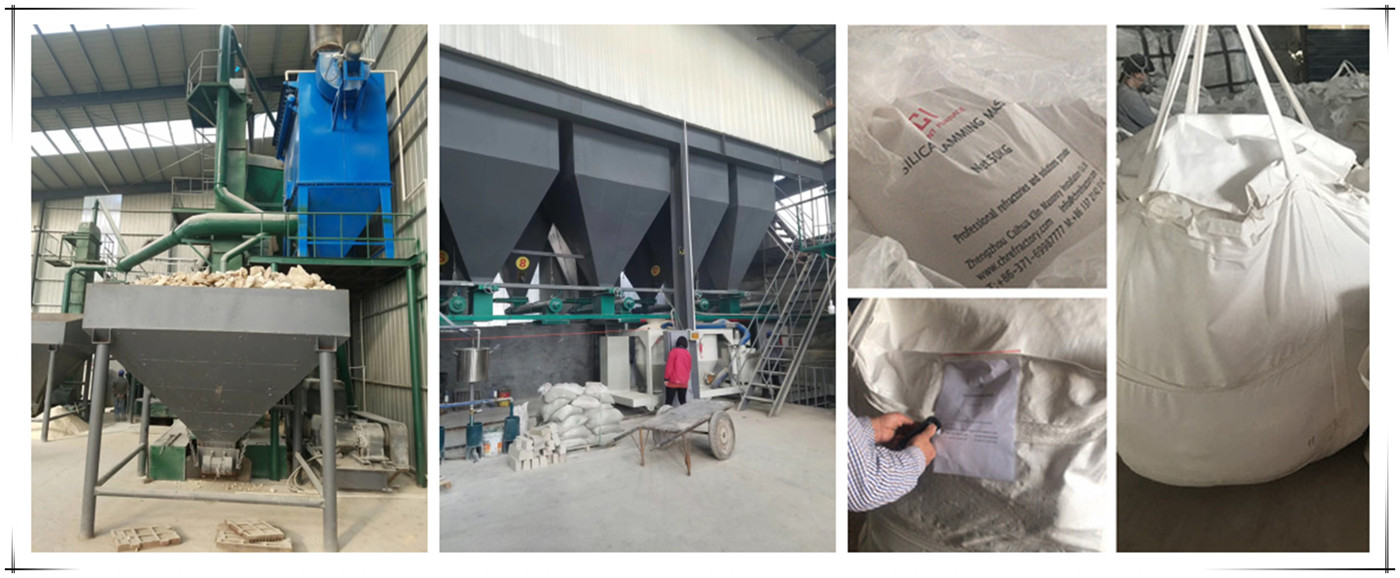

Using high quality magnesia as the main materials, by adding compound binding additives, this series of gunning mixes for EAF feature high adhesive strength, low rebound rate, good sintering, good erosion resistance, and can be used as cold or hot repair materials at slag line and side wall.

Using high quality magnesia as the main materials, by adding compound binding additives, this series of gunning mixes for EAF feature high adhesive strength, low rebound rate, good sintering, good erosion resistance, and can be used as cold or hot repair materials at slag line and side wall.

|

Brand |

CHDPB-87 |

CHDPB-75 |

CHDPB-65 |

|

MgO/ % |

≧87 |

≧75 |

≧65 |

|

CaO/ % |

—– |

≦10 |

≦30 |

|

Bulk density/g·cm3 |

≧2.60 |

≧2.40 |

≧2.30 |

|

Cold crushing strength/ MPa

|

≧15 (110°C , 24h) |

≧15 (110°C , 24h) |

≧15 (110°C , 24h) |

|

≧25 (1500°C , 3h) |

≧20 (1500°C , 3h) |

≧20 (1500°C , 3h) |

|

|

Permanent linear change/% |

0~-1.5(1500°C, 3h) |

0~-2.5(1500°C, 3h) |

0~-3.0(1500°C, 3h) |

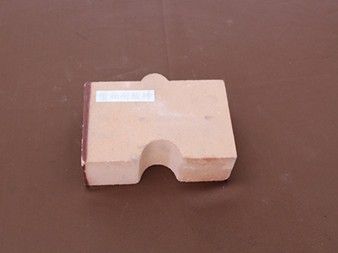

The acid-resistant refractory bricks produced by our company adopt high-grade refractory aggregates, powders, additives, etc. After reasonable grading and high-temperature firing, they can fully meet the acid and high temperature resistance of furnace lining refractories under various acid regeneration process conditions.

Dry anti-seepage refractories works well with simple construction, good thermal insulation effect and strong anti-permeability. The working principle of Dry anti-seepage refractory material is to react alkali ions in materials and metal liquids at high temperature, form isolation layer on the surface, prevent sodium salt from going to cathode block.

The high-strength wear-resistant self-flowing castables are made of high-quality bauxite clinker, mullite and fused corundum. The pure calcium aluminate cement, corundum micro-powder and silicon micro-powder are used as binders.

If you need our products please write down any questions, we will reply as soon as possible.