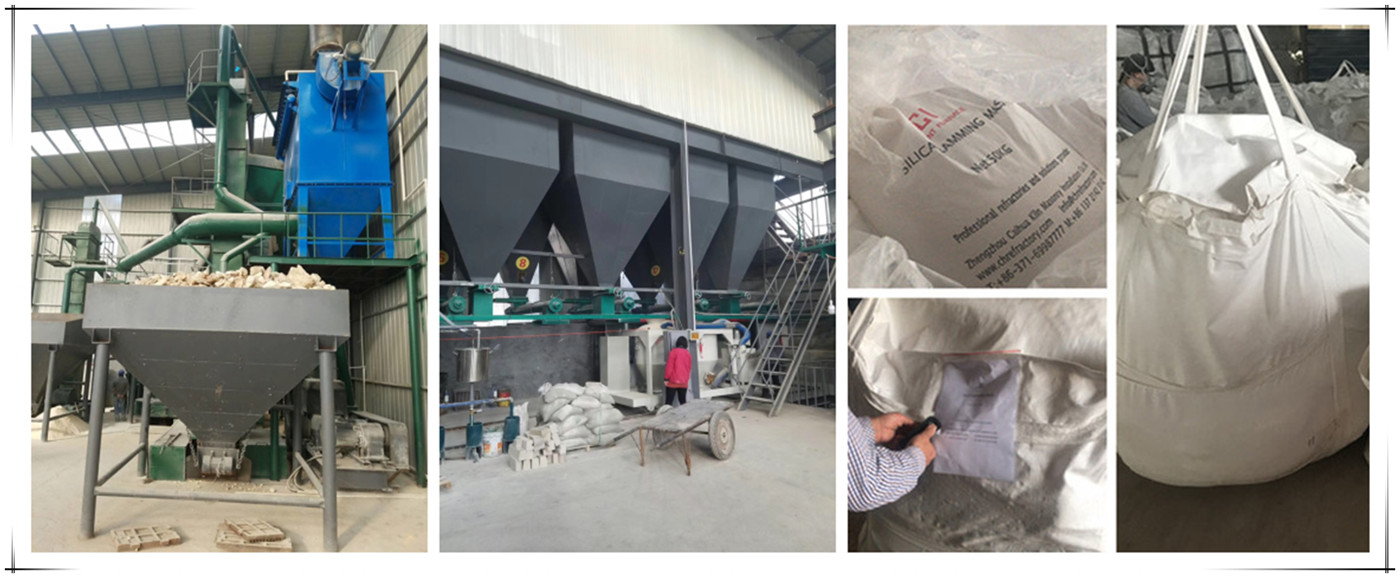

Main raw materials of Ladle Working layer gunning mix are corundum and magnesium aluminate spinel, after spraying use on the working layer surface in carbon-free ladle.

Main raw materials of Ladle Working layer gunning mix are corundum and magnesium aluminate spinel, after spraying use on the working layer surface in carbon-free ladle, characteristic appear as follow:

●This Ladle Working layer gunning mix could be endlessly cycle used to lower the refractory materials consumption and waste appearance and work with key role on the ladle continue and safety use.

●Wet spraying technique has no pollute to environment and no CO2、CO when using in carbon-free ladle,and it’s geared to the carbon free and environment- protected and environment friendly technique.

●This Ladle Working layer gunning mix has no pollute to the molten steel, and, compared with the current lining materials, it has the characteristic that long lifetime, low cost, high construction automaticity, and energy conservation and environment protection. High potential value among the inland steel enterprise.

|

Product code |

CH-GBP85 |

CH-GBP88 |

|

Al2O3/% |

≧85 |

≧88 |

|

Apparent porosity/% |

≦12 |

≦11 |

|

Bulk density/g.cm3 |

≧2.80 |

≧2.90 |

|

Cold Crushing Strength/MPa |

≧60 |

≧70 |

|

Permanent Linear Change/% |

0~+1.5 (1550℃,3h) |

0~+1.5 (1550℃,3h) |

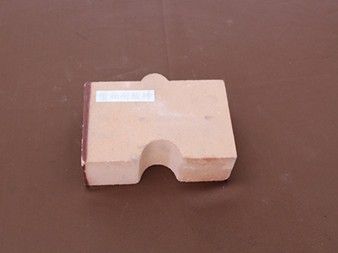

The acid-resistant refractory bricks produced by our company adopt high-grade refractory aggregates, powders, additives, etc. After reasonable grading and high-temperature firing, they can fully meet the acid and high temperature resistance of furnace lining refractories under various acid regeneration process conditions.

Composite spinel firebrick is a product obtained by high-pressure molding and high-temperature sintering using high-purity magnesia andmagnesia-chromium composite spinel as main raw materials.

Upper and lower nozzles are resin bonded products based on corundum, magnesium aluminate spinel and graphite as main raw materials. Nozzle and well block for ladle have excellent thermal shock resistance, high temperature strength and good corrosion and erosion resistance.

If you need our products please write down any questions, we will reply as soon as possible.