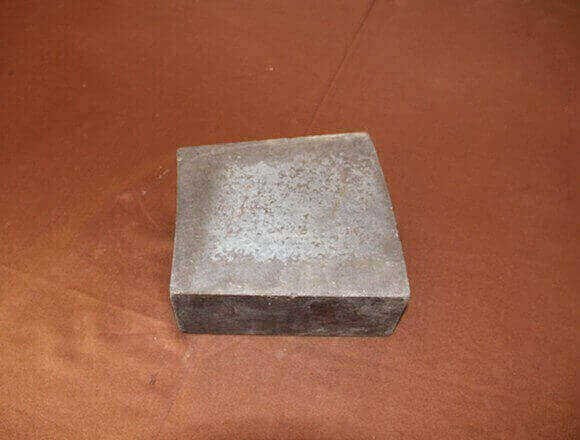

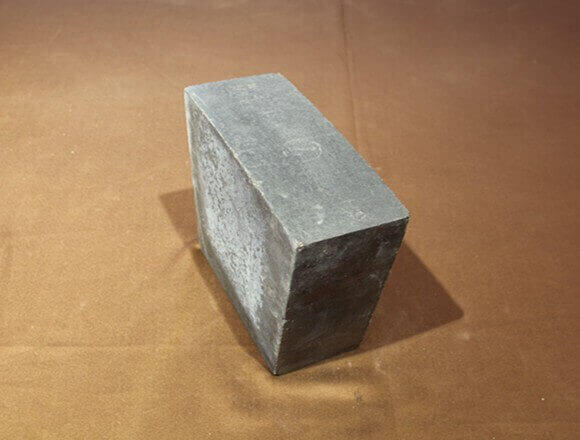

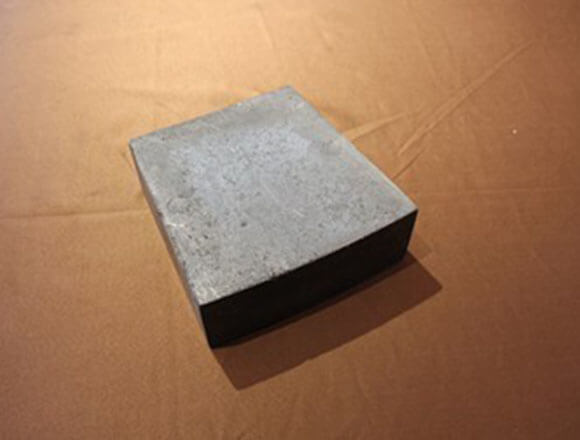

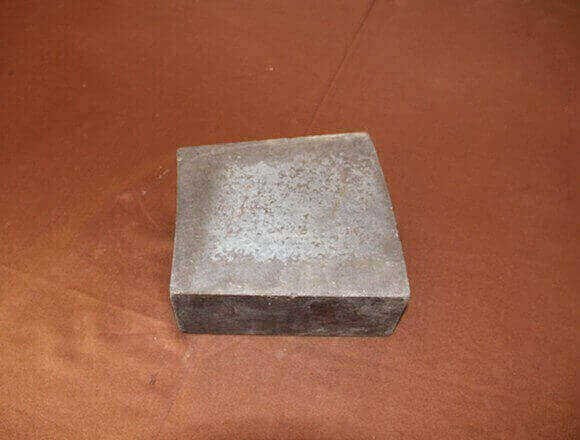

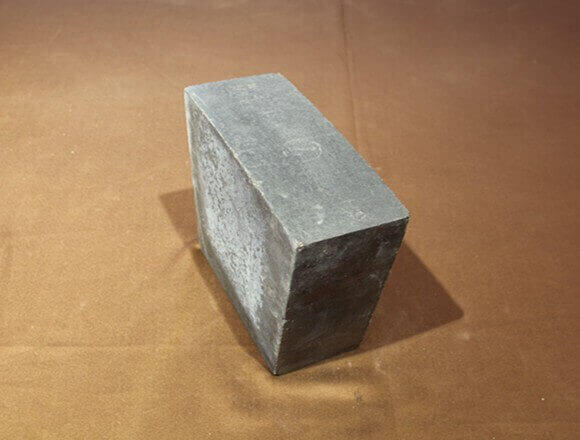

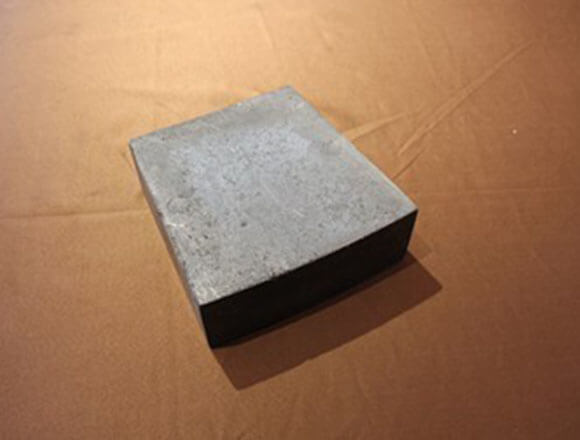

Base on high quality magnesite and graphite as main raw materials, low carbon MgO-C bricks are produced via pressing and low temperature pre-baking and mainly used in slag zone of ladle lined with low carbon or carbon-free refractories for low and ultra-low steel production.

Base on high quality magnesite and graphite as main raw materials, low carbon MgO-C bricks are produced via pressing and low temperature pre-baking and mainly used in slag zone of ladle lined with low carbon or carbon-free refractories for low and ultra-low steel production. Low carbon MgO-C brick has high strength, good corrosion resistance and excellent thermal shock resistance.

|

Product code |

CH-MT5A |

CH-MT5B |

CH-MT5C |

CH-MT3A |

CH-MT3B |

CH-MT3C |

|

MgO/% |

≧85 |

≧84 |

≧82 |

≧86 |

≧85 |

≧83 |

|

C/% |

≦5 |

≦5 |

≦5 |

≦3 |

≦3 |

≦3 |

|

Apparent porosity/% |

≦5 |

≦6 |

≦7 |

≦8 |

≦9 |

≦10 |

|

Bulk density/g.cm3 |

≧3.00 |

≧2.98 |

≧2.96 |

≧3.03 |

≧3.00 |

≧2.98 |

|

Cold Crushing Strength/MPa |

≧40 |

≧40 |

≧35 |

≧40 |

≧40 |

≧35 |

|

Application |

The slag line and sidewall of ladle working lining for low carbon steel production |

|||||

Electro-fused AZS hot refractroy repair material uses fused cast corundum refractory as raw material, adding α-alumina micro-powder to the furnish, adopting new generation ceramic binder, adding special component ultrafine powder and introducing dispersing medium, modified adding phase and chemical adding phase.

Magnesia mortar for fire bricks is made from high-quality magnesite, magnesia mortar performs well in use with excellent workability, desirable hardening time, high adhesive strength, and good corrosion resistance under high temperature.

The appropriative refractory castable for tertiary air duct has the characteristics of high strength, good wear resistance, erosion resistance, erosion resistance and no cracking.

If you need our products please write down any questions, we will reply as soon as possible.