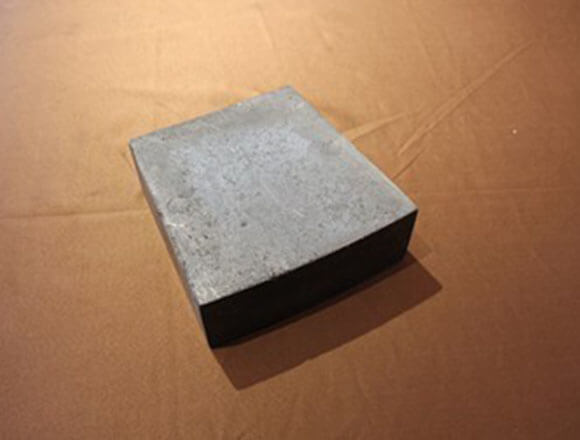

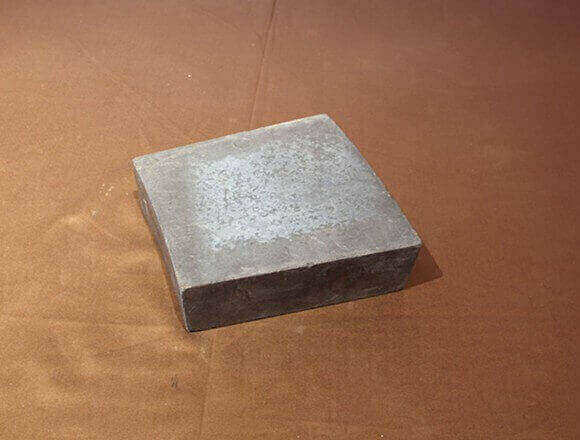

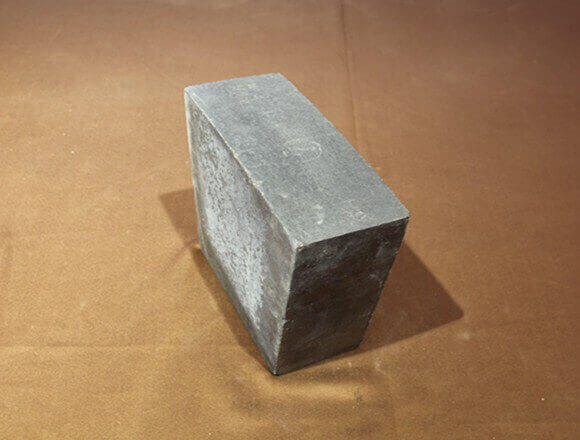

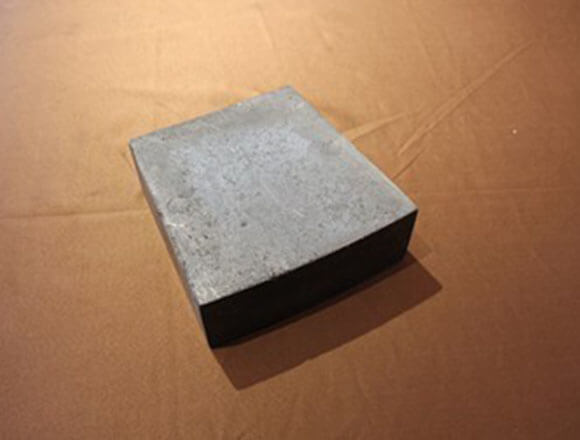

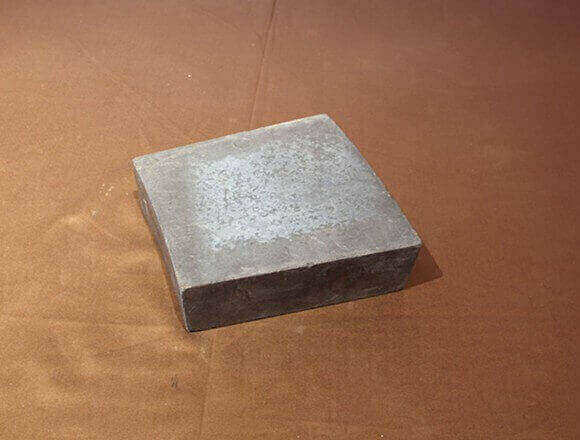

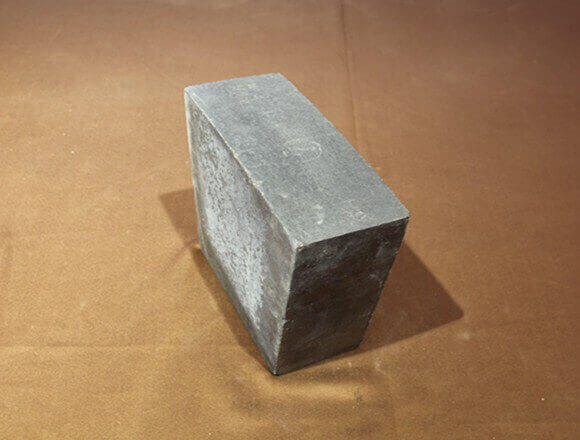

Fused alumina, magnesium aluminate spinel, fused MgO and graphite are the main raw materials in use for Low carbon corundum-spinel brick. Low carbon corundum-spinel bricks, featured with high strength, better corrosion resistance and thermal shock resistance, are mainly used in the bottom and sidewall for low and ultra-low carbon steel production.

Fused alumina, magnesium aluminate spinel, fused MgO and graphite are the main raw materials in use for Low carbon corundum-spinel brick. Low carbon corundum-spinel bricks, featured with high strength, better corrosion resistance and thermal shock resistance, are mainly used in the bottom and sidewall for low and ultra-low carbon steel production.

|

Product code |

CH-LMT80 |

CH-LMT85 |

CH-LMT88 |

|

Al2O3/% |

≧80 |

≧85 |

≧88 |

|

MgO/% |

≧5 |

≧4 |

≧3 |

|

C/% |

≦5 |

≦5 |

≦5 |

|

Apparent porosity/% |

≦8 |

≦8 |

≦8 |

|

Bulk density/g.cm3 |

≧2.90 |

≧2.95 |

≧3.0 |

|

Cold Crushing Strength/MPa |

≧35 |

≧40 |

≧45 |

|

Application |

The sidewall and bottom of ladle working lining for low carbon steel production |

||

Dry anti-seepage refractories works well with simple construction, good thermal insulation effect and strong anti-permeability. The working principle of Dry anti-seepage refractory material is to react alkali ions in materials and metal liquids at high temperature, form isolation layer on the surface, prevent sodium salt from going to cathode block.

Wear-resistant plastic, which is made of special grade alumina, mullite, corundum, siliconcarbide as aggregate and matrix material, mixed by adding binder, additive and plasticizer.

Composite spinel firebrick is a product obtained by high-pressure molding and high-temperature sintering using high-purity magnesia andmagnesia-chromium composite spinel as main raw materials.

If you need our products please write down any questions, we will reply as soon as possible.