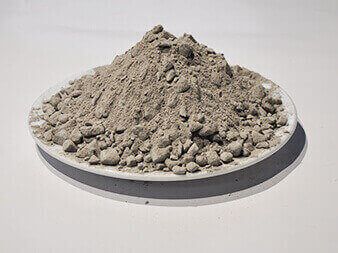

The tap hole clay is used to block the taphole plays an irreplaceable role in ensuring stable and high production of the blast furnace, improving the working strength and environment before the furnace, and prolonging the service life of the blast furnace.

High alumina castable is a kind of refractory castable which uses high alumina raw materials as aggregates and the powder and then be added with binding agent. High aluminum castable refractories has high mechanical strength, good thermal shock resistance, good corrosion resistance.

The high strength castable refractory steel fiber reinforced wear-resistant castable is prepared by adding special grade aluminum bauxite clinker or corundum as aggregate and powder, adding binder, admixture and heat-resistant stainless steel fiber.

Refractory clay mortar is referred to as soft clay. It isair setting refractory mortar, a refractory clay with plasticity. The constituent minerals of high temperature mortar are mainly kaolinite and hydromica. Generally, refractory mortar mix contains Al2O3 ≥ 22% ~ 30%, SiO 2 ≥ 42% ~73%, and the refractoriness is 1580 ~ 1670 °C.

Low cement refractory castable made by CH Refractories with three levels, which are high aluminum low cement castable, mullite low cement castable and corundum low cement castable.

The iron runner castable that developed by CH Refractories is low cement Al2O3-SiC-C ramming mass, and self-flowing refractory castable, which divided three levels to meet different sizes of blast furnace iron runner and achieved very good performance.

Lightweight thermal insulating castable is formulated with different types of lightweight aggregates, powders, binders and expansion agents. lightweight castable refractory is a good new type of refractory insulation materials and energy-saving materials.

The high-strength wear-resistant self-flowing castables are made of high-quality bauxite clinker, mullite and fused corundum. The pure calcium aluminate cement, corundum micro-powder and silicon micro-powder are used as binders.

Corundum castable refractory is divided into cement-free corundum castable refractory and cement corundum castable refractory. Also there are different kinds of corundum castables refractory made by CH refractories company according to different raw material.

The EAF refractory gunning mix uses high quality magnesia as the main materials, by adding compound binding additives, the series of gunning mixes for EAF refractory repairs feature high adhesive strength, low rebound rate, good sintering, good erosion resistance, and can be used as cold or hot refractory repairs materials at slag line and side wall.

There are mainly four refractory materials for furnace in CH Refractories, which are pre-mix silica ramming mass and neutral ramming mass for induction furnace, magnesia refractory mix for EAF bottom, and Electro-fused AZS refractory ramming mass for glass kiln.

The heat resistant refractory cement also well known as calcium aluminate cements, and high alumina castable refractory cement. Generally there are 4 grades of refractory cement according to Al2O3 content, A600, A700,A900 and CA-70.