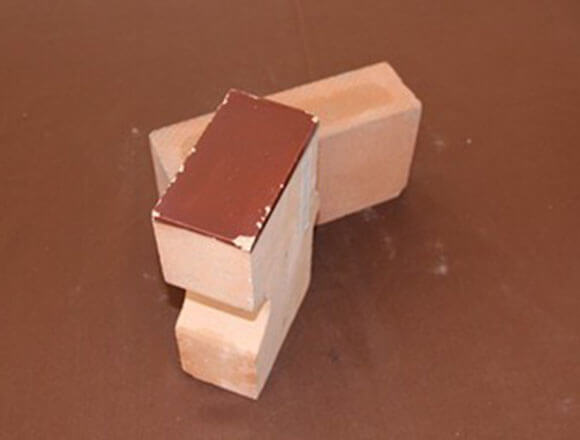

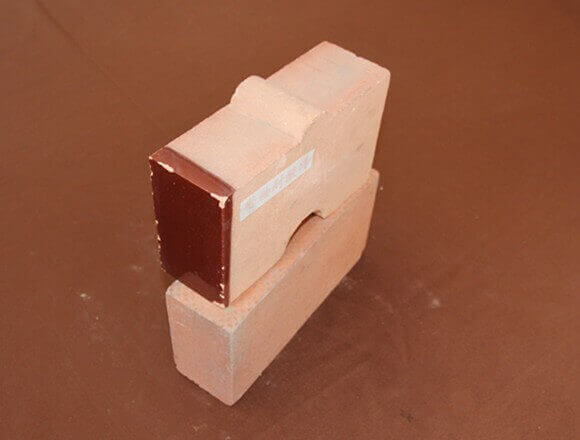

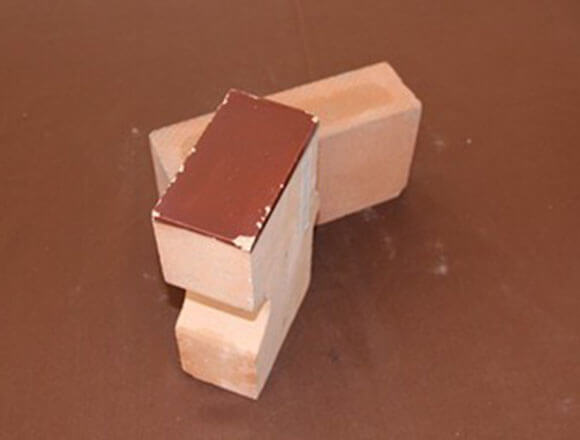

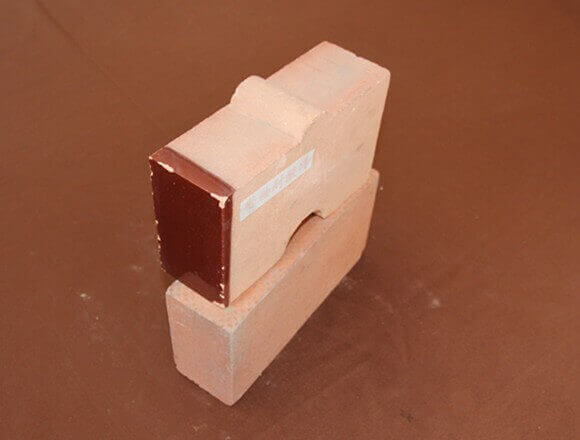

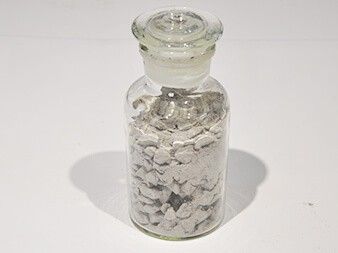

The acid-resistant refractory bricks produced by our company adopt high-grade refractory aggregates, powders, additives, etc. After reasonable grading and high-temperature firing, they can fully meet the acid and high temperature resistance of furnace lining refractories under various acid regeneration process conditions.

The acid-resistant refractory bricks produced by our company adopt high-grade refractory aggregates, powders, additives, etc. After reasonable grading and high-temperature firing, they can fully meet the acid and high temperature resistance of furnace lining refractories under various acid regeneration process conditions. High strength, anti-scour, long life and other features.

|

Index |

(Absmption of water)% |

Normal temperature compressive strength(Mpa)

|

Acidproof(%) |

Bulk density(g/cm3)

|

Heating line change(300℃)

|

|

NSZ-1.0 |

≤15 |

≥10.0 |

≥96 |

≤1.0 |

≤0.1 |

|

NSZ-1.3 |

≤13 |

≥15 |

≥96 |

≤1.3 |

≤0.1 |

|

NSZ-1.8 |

≤12 |

≥20.0 |

≥96 |

≤1.8 |

≤0.1 |

Base on high quality magnesite and graphite as main raw materials, low carbon MgO-C bricks are produced via pressing and low temperature pre-baking and mainly used in slag zone of ladle lined with low carbon or carbon-free refractories for low and ultra-low steel production.

Fast Drying Castable for Iron Notch is made of corundum, high quality bauxite and silicon carbide incorporated with appropriate drying agent. By firing 2 to 3 hours, the products can be put into use, and show excellent performance.

The Unburned slide gate plates series products are made of corundum, mullite, and high-quality clinker clinker. Unburned slide gate plates are made by adding flake graphite, silicon carbide, and silicon metal powder, which are made by high-pressure molding, low-temperature heat treatment and grinding.

If you need our products please write down any questions, we will reply as soon as possible.