In the high temperature state, the anti-crust refractory castable forms a glaze layer on the surface of the material, preventing the penetration of the glass phase in the cement raw material, thereby playing an anti-skinning effect.

In the high temperature state, the anti-crust refractory castable forms a glaze layer on the surface of the material, preventing the penetration of the glass phase in the cement raw material, thereby playing an anti-skinning effect. The anti-crust refractory material is mainlyused for the easy skinning of the cyclonepreheater cutting slope, rising flue, preheater cone and other parts.

|

Items |

CH-KJZL55 |

CH-KJZL60 |

|

|

SiC +SiO2 /% ≥ |

55 |

60 |

|

|

Bulk density (110℃×24h) g/cm3 ≥ |

2.4 |

2.5 |

|

|

Flexural strength/ MPa ≥

|

110℃×24h |

8 |

10 |

|

1100℃×3h |

9 |

11 |

|

|

Compressive strength/ MPa ≥

|

110℃×24h |

60 |

70 |

|

1100℃×3h |

70 |

80 |

|

|

Permanent Linear Change /% (1100℃×3h) ≤ |

±0.4 |

±0.4 |

|

|

Alkai resistance |

1~2 |

1~2 |

|

|

Maximum Service temperature/℃ |

1300 |

1400 |

|

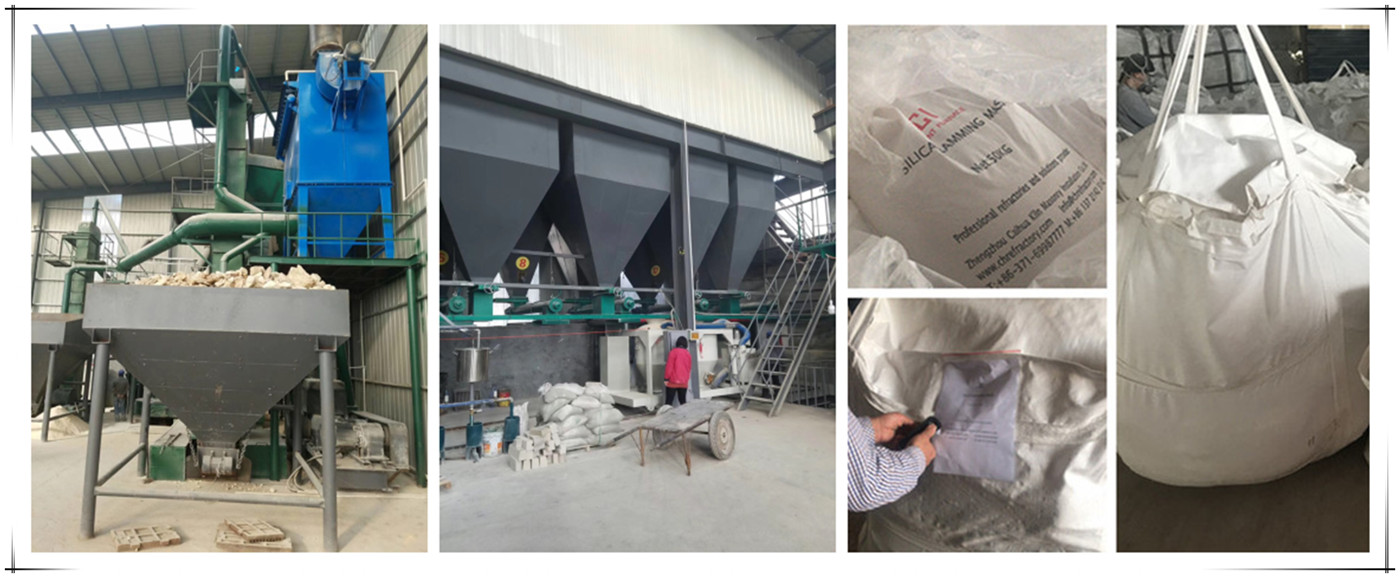

Using high quality magnesia as the main materials, by adding compound binding additives, this series of gunning mixes for EAF feature high adhesive strength, low rebound rate, good sintering, good erosion resistance, and can be used as cold or hot repair materials at slag line and side wall.

Refractory castable for rotary kiln is suitable for calcination and roasting of cement, limestone,magnesia, ilmenite and non-ferrous metal ore. Castable for rotary kiln has the advantages of strong acid and alkali corrosion resistance and good wear resistance and long service life.

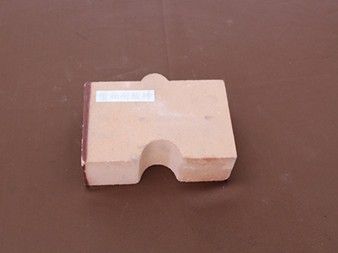

The acid-resistant refractory bricks produced by our company adopt high-grade refractory aggregates, powders, additives, etc. After reasonable grading and high-temperature firing, they can fully meet the acid and high temperature resistance of furnace lining refractories under various acid regeneration process conditions.

If you need our products please write down any questions, we will reply as soon as possible.