CH Refractories manufactured casting powder is widely applied for both opening and protected CCM casting condition as well as molded casting . Our engineer will design each order of casting powder composition according to steel grade, casting speed, and other related casting condition.

|

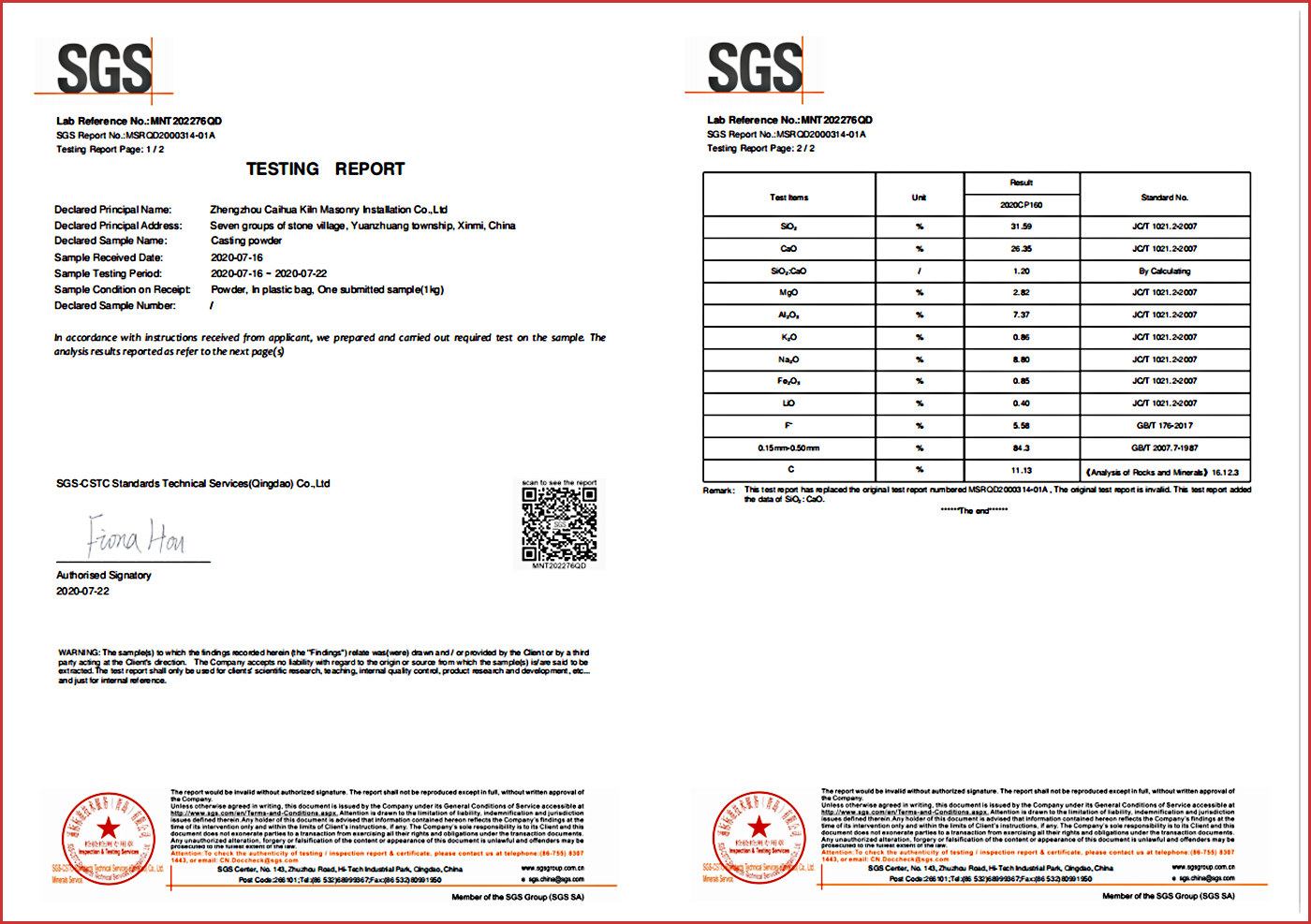

SiO2 |

% |

29-32 |

|

Cao |

% |

26-29 |

|

MgO |

% |

2-4 |

|

Al2O3 |

% |

5-8 |

|

Na2O |

% |

6-9 |

|

K2O |

% |

≤1 |

|

Fe2O3 |

% |

≤1 |

|

LiO |

% |

≤1•5 |

|

F |

% |

≤7 |

|

Fixed C |

% |

10-15 |

|

Basicity |

|

1±0•5 |

|

Melting point |

℃ |

1100 |

|

Viscosity, 1300℃ |

Pa• S |

5-6 |

|

Grain size, 0•15-0•5mm |

% |

≥80 |

The submerged entry nozzle continuous casting protects the liquid steel from being oxidized by the ambient air when it flows into the crystallizer from the tundish.

The EAF refractory gunning mix uses high quality magnesia as the main materials, by adding compound binding additives, the series of gunning mixes for EAF refractory repairs feature high adhesive strength, low rebound rate, good sintering, good erosion resistance, and can be used as cold or hot refractory repairs materials at slag line and side wall.

Mullite insulating brick made by CH refractories is JM series according to international standard. Because jm23 insulation brick with smaller bulk density whose strength is not as strong as heavy weight fire bricks, when delivering, CH Refractories will package mullite insulating brick with special packages to protect mullite bricks from damage.

If you need our products please write down any questions, we will reply as soon as possible.