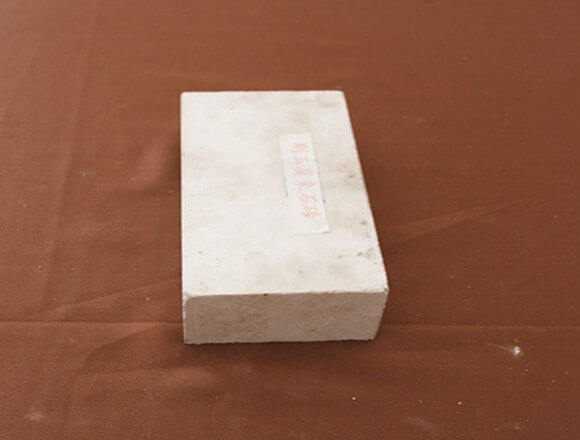

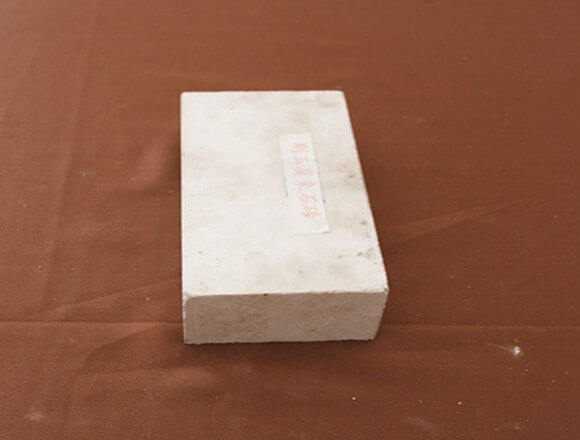

Corundum mullite firebrick uses corundum and mullite as aggregate and fine powder, adding appropriate additives. Corundum mullite fireproof brick is formed by high-pressure and sintered at medium-temperature through reasonable process ratio.

Corundum mullite firebrick uses corundum and mullite as aggregate and fine powder, adding appropriate additives. Corundum mullite fireproof brick is formed by high-pressure and sintered at medium-temperature through reasonable process ratio. Corundum mullite refractory brick has high bulk density, high compressive strength, good thermal shocking resistance,and good corrosion resistances to acids and alkali.

Advantages of Corundum Mullite Brick

●Low porosity and strong peeling resistance

●Customerize mould according to different size requirements for free

Application of Corundum Mullite Brick

Generally used in safety and transition zone

|

Brand |

Refractoriness /℃≥ |

Bulk density g/cm3 ≥ |

Apparent porosity/% ≤ |

CCS /Mpa ≥ |

0.2MpaRefractory under load/℃ ≥ |

Thermal stability/ time(1100℃)≥ |

Al2O3 %≥ |

|

CH-GM80 |

1780 |

2.7 |

19 |

100 |

1500 |

35 |

80 |

This product has high thermal strength, strong wear resistance, excellent corrosion resistance and high temperature volume stability, effectively extending the service life of CFGboilers. Can be used for the wear lining of various CFB boilers.

Zhengzhou Caihua can supply silica-based and Chrome-based fillers according to customer's requirement. Silica based filler use quartz sand as raw materials, mixed with lubricant and sintering aid.

Checker Brick is a kind of heat-transfer medium, which is mainly used for middle-upper part of regenerative chamber in hot blast stove for thermal storage in the burning period.

If you need our products please write down any questions, we will reply as soon as possible.