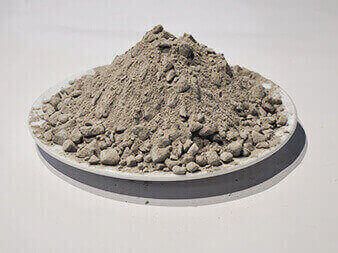

Electro-fused AZS refractory ramming mass is monolithic refractories and electro-fused AZS refractory ramming mix is composed of molten corundum aggregate particles and a small amount of additives.

Electro-fused AZS refractory ramming mass is monolithic refractories and electro-fused AZS refractory ramming mix is composed of molten corundum aggregate particles and a small amount of additives. Electro-fused AZS refractory ramming mass is prepared by using high-quality zirconium aggregate, powder material, aluminum phosphate as binder and admixture, which has low thermal conductivity, good thermal shock resistance, chemical stability and melting. Glass and liquid metal have good corrosion resistance, work stability under oxidizing atmosphere, and do not chemically react with molten metal. Electro-fused AZS ramming material is an excellent thermosetting amorphous refractory material.

Advantages of Electro-fused AZS Ramming Mass:

● convenient for use

● small thermal expansion and shrinkage

● strong resistance to solution corrosion.

● hardening at normal temperature, high compressive strength in high temperature

Applications of Electro-fused AZS Ramming Mass:

●Sealing layer of glass and frit bath kiln.

●Used in the field of glass furnace kiln, ladle and circulating fluidized bedboiler.

|

Items |

Fused AZS ramming mass |

|

ZrO2 % ≥ |

28 |

|

Bulk density g/cm3 ≥ |

2.9 |

|

Normal temperature compressive strength MPa 110℃drying ≥ |

50 |

|

Refractoriness /℃ ≥ |

1770 |

|

Maximum Service temperature/℃ |

1650 |

|

Use density kg/m3 |

3000 |

Various kinds of fire proof mortars are available at Zhengzhou CH Refractories, which include corundum based, corundum Cr2O3 based, high alumina based and Al203-MgO based.

Al2O3-SiC Castable for Metal Mixer is developed with high quality bauxite, corundum and SiC as the main raw materials, and bonded by low cement or ultra-low cement.

Dry rammmg mixes for EAF bottom are made from high quality magnesite and Fe2O3-CaO magnesite, and show the features of excellent resistance against steel penetration, superior erosion resistance, easily-sintering, high bulk density and easy installation.

If you need our products please write down any questions, we will reply as soon as possible.