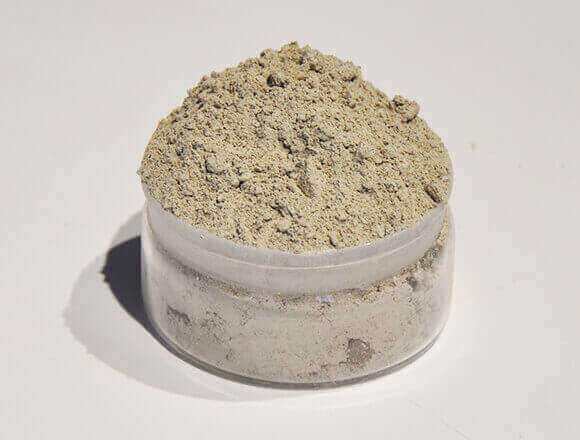

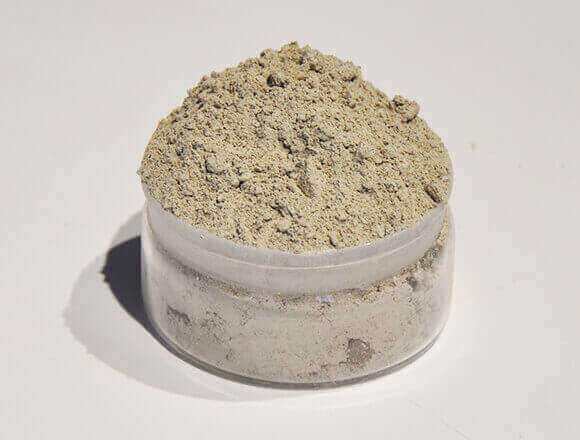

Lightweight thermal insulating castable is formulated with different types of lightweight aggregates, powders, binders and expansion agents. lightweight castable refractory is a good new type of refractory insulation materials and energy-saving materials.

Lightweight thermal insulating castable is formulated with different types of lightweight aggregates, powders, binders and expansion agents. lightweight castable refractory is a good new type of refractory insulation materials and energy-saving materials. Lightweight refractory castable has the characteristics of high strength, small bulk density, low thermal conductivity, good thermal insulation performance and convenient construction, and such insulation refractories is applied to the heat insulation parts of various kilns.

Insulation castable is easy to be constructed, is the best construction product for the high temperature alkali resistant parts. Good workability, strong cohesion, initial setting time and construction can be a long time, fast strength growth, strong impermeability, no acidification, easy to ensure that the masonry plaster full and dense, can significantly improve the chimney liner air tightness, integrity and anti-corrosion ability. Refractory castable insulation is an ideal cementing material for high chimneys, high temperature flue and duct lining. Insulating castable refractory can also be used in acid tank and other acid resistant parts in petroleum, chemical, nonferrous metallurgy and so on.

Applications of Insulation Castable:

• Heating furnace of metallurgical industry

• Petroleum, chemical industry, electric power industry

• Engineering industry furnace and thermal equipment

Advantages of Insulation Castable:

• Easy to construct

• High strength,

•Good insulating property,

•Good thermal shock resistance.

|

Items |

CH-QJ-0.6 |

CH-QJ-0.8 |

CH-QJ-1.0 |

CH-QJ-1.2 |

CH-QJ-1.4 |

CH-QJ-1.6 |

|

Bulk density g/cm3 ≥ |

0.6 |

0.8 |

1.0 |

1.2 |

1.4 |

1.6 |

|

Compressive strength (110℃×24h) MPa ≥ |

1.5 |

2 |

3 |

4 |

8 |

18 |

|

PLC (800℃×3h)/ % |

0~1.7 |

0~1.5 |

0~1.2 |

0~0.8 |

0~0.7 |

0~0.6 |

|

Thermal Conductivity (350±25℃) W/m.k ≤ |

0.20 |

0.25 |

0.35 |

0.45 |

0.60 |

0.70 |

|

Application temp /℃≤ |

620 |

800 |

1000 |

1100 |

1200 |

1300 |

The submerged entry nozzle continuous casting protects the liquid steel from being oxidized by the ambient air when it flows into the crystallizer from the tundish.

Zirconium corundum brick is also named AZS brick. It is based on three chemical components of the Al2O3-ZrO2-SiO2 ternary phase diagram and widely used for glass kiln. The glass kiln brick is arranged according to the order of its contents.

The heat resistant refractory cement also well known as calcium aluminate cements, and high alumina castable refractory cement. Generally there are 4 grades of refractory cement according to Al2O3 content, A600, A700,A900 and CA-70.

If you need our products please write down any questions, we will reply as soon as possible.