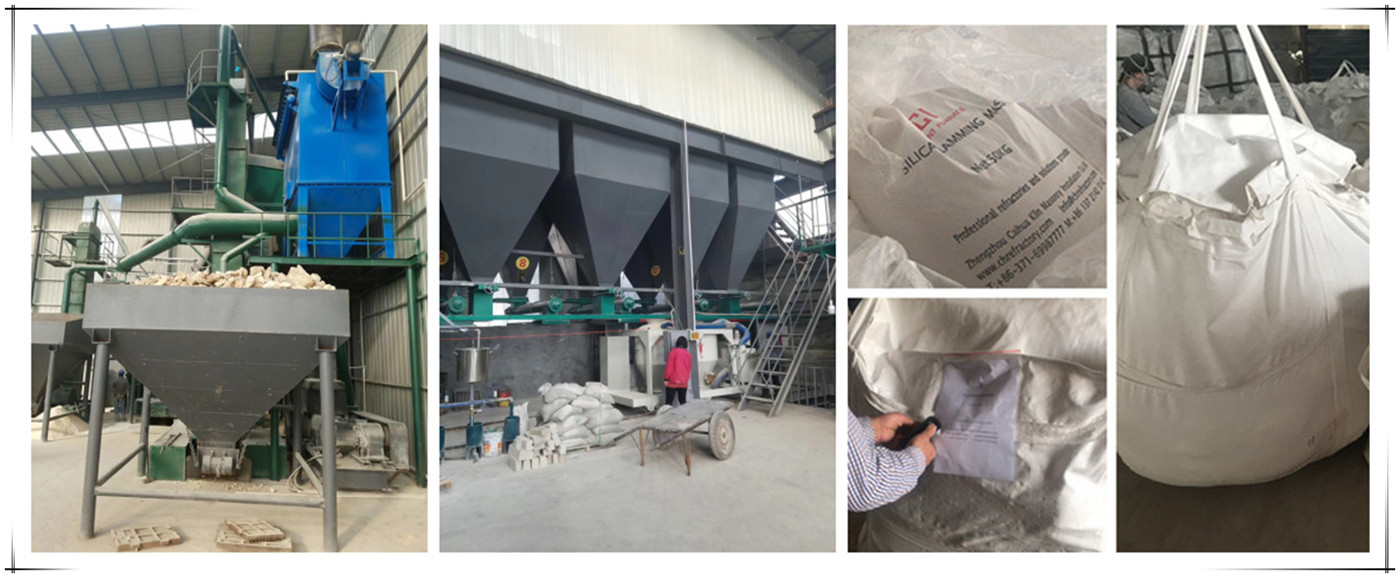

Low cement refractory castable made by CH Refractories with three levels, which are high aluminum low cement castable, mullite low cement castable and corundum low cement castable.

Low cement refractory castable made by CH Refractories with three levels, which are high aluminum low cement castable, mullite low cement castable and corundum low cement castable. The low cement fireproof castable is mainly used for cement kiln masonry,especially for kiln mouth, kiln door cover, cooler, tertiary air duct and coal injection pipe.

The low cement castable made by CH Refractories can be made into fast drying explosion-proof castable according to baking time requirements, which has following advantages comparing with common refractory castable:

. The water consumption is less, only 1/2-1/3(about 5-7%) of common refractory castables, so the bulk density is high, the porosity is low, no obvious dehydration stage when baking, and the thermal shock performance is good, which is comparable to the sintered products.

. The high temperature performance and slag resistance of the material are improved compare with common refractory castable, because the amount of cement is greatly reduced,

. After curing, there are few hydrates or anhydrous compounds, and no hydration bond is destroyed during baking, which affects the medium temperature strength or high temperature strength.

Applications of Low Cement Castable:

•Cement kiln

•Heating furnace

•Recirculating fluidized bed boiler

•Chemical industry and construction industry

•Tundish lining

Advantages of Low Cement Castable:

•Higher strength than common castable

•Made from high quality raw material

•Excellent strength at various temperatures

•Good thermal shock resistance

|

Ltems |

High aluminum |

Mullite |

Corundum |

|

|

|

CH-LCC65 |

CH-LCC70 |

CH-LCC85 |

|

|

AL2O3 % ≥ |

65 |

70 |

85 |

|

|

Bulk density (110℃×24h) g/cm3 ≥ |

2.5 |

2.6 |

2.8 |

|

|

Flexural strength/ MPa ≥

|

110℃×24h |

10 |

11 |

12 |

|

1400℃×3h |

12 |

13 |

14 |

|

|

Compressive strength/MPa ≥

|

110℃×24h |

80 |

90 |

100 |

|

1400℃×3h |

90 |

90 |

100 |

|

|

PLC(1400℃×3h)/ % ≤ |

±0.5 |

±0.5 |

±0.5 |

|

|

Maximum Service temperature/℃ |

1500 |

1550 |

1600 |

|

The anchor refractory brick is also called hanger brick. The anchor brick is similar to the material of the furnace lining castable, shaped by machine pressing, high temperature fired,has good thermal shock resistance and high strength,and is used on multiple heating furnaces to achieve good performance.

The heat resistant refractory cement also well known as calcium aluminate cements, and high alumina castable refractory cement. Generally there are 4 grades of refractory cement according to Al2O3 content, A600, A700,A900 and CA-70.

CH Refractories manufactures different types of ladle slide gate plates for various capacity ladles, can meet different service life requirements. Generally the ladle slide gate plate is divided into fired and un-fired type according to different casting conditions and service life.

If you need our products please write down any questions, we will reply as soon as possible.