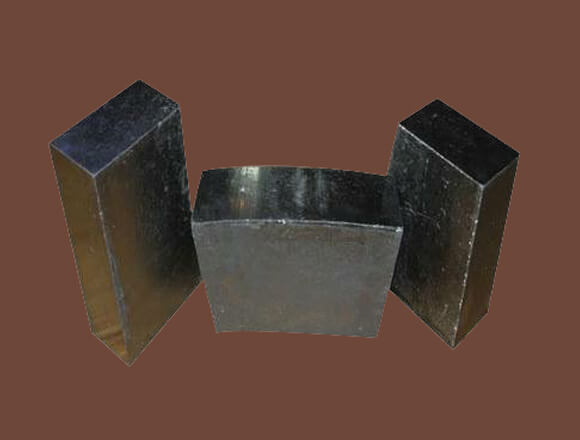

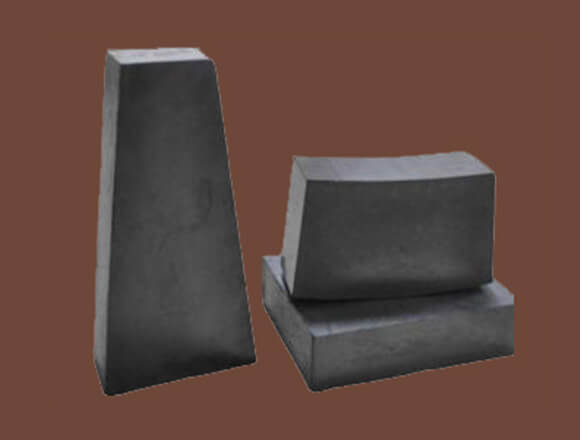

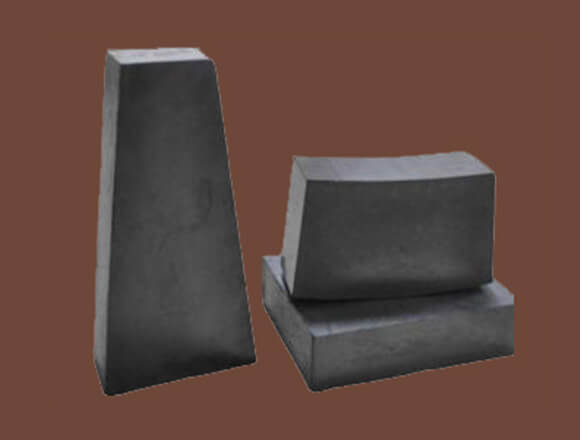

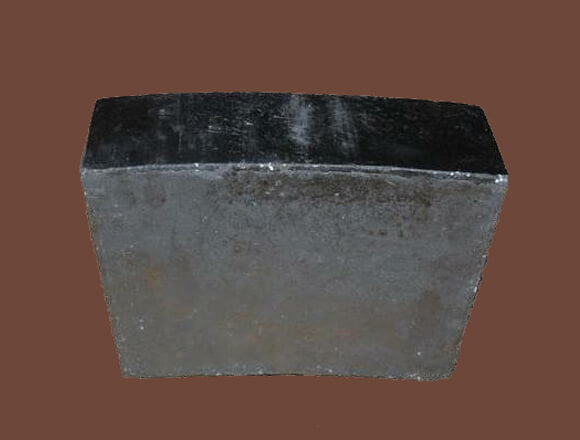

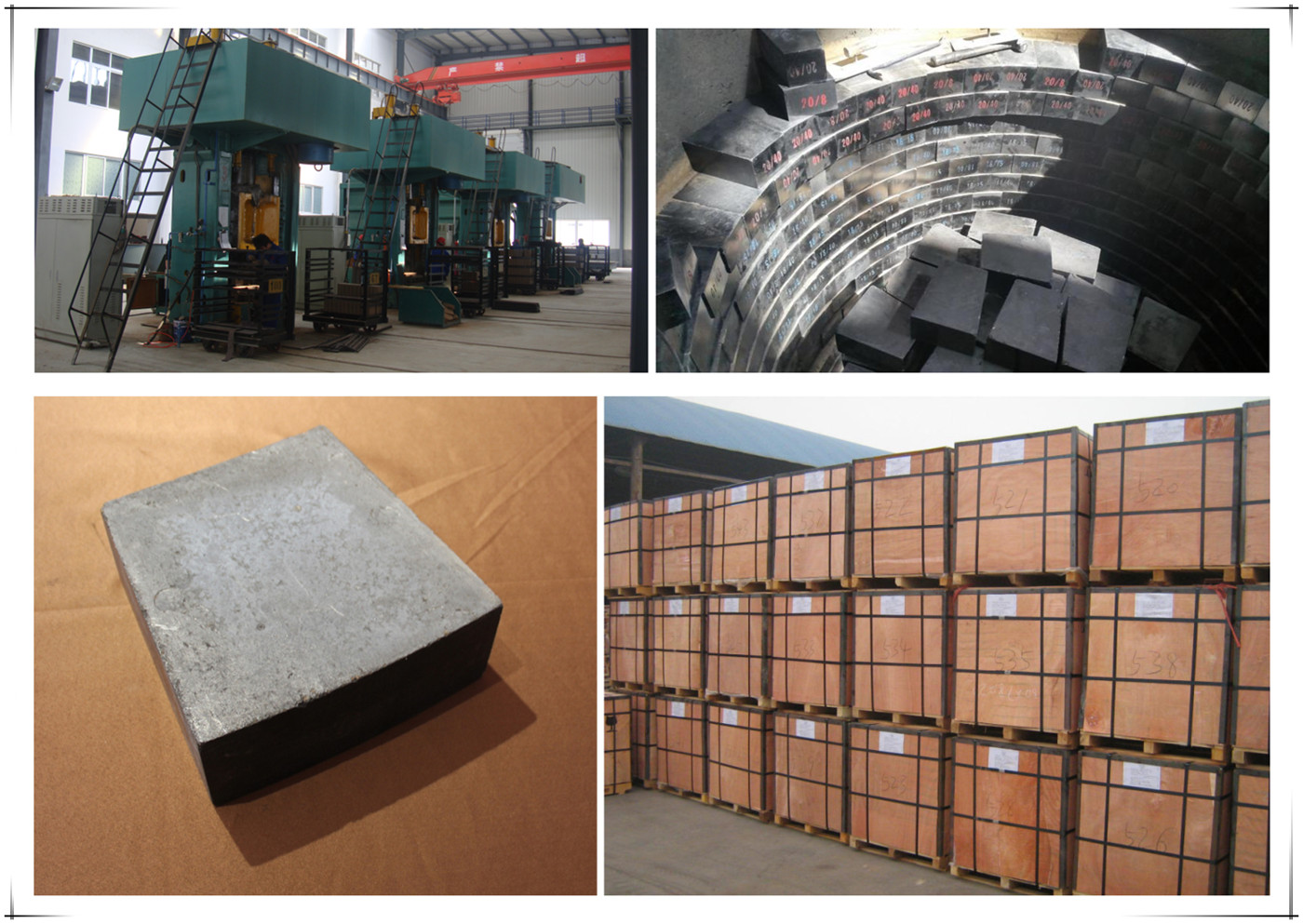

Mag carbon bricks are made of fused magnesia, high-purity magnesia and graphite, and are formed by high pressure molding and low temperature treatment. Different grades of mag carbon bricks can be selected according to different smelting conditions , service life in heats and smelting steel grades.

Mag carbon bricks are made of fused magnesia, high-purity magnesia and graphite, and are formed by high pressure molding and low temperature treatment. Different grades of mag carbon bricks can be selected according to different smelting conditions , service life in heats and smelting steel grades.

CH refractories will provide free design of alumina magnesia carbon bricks lining for your ladle, (EAF)electric arc furnace refractory lining and blast furnace refractory, according to your furnace working condition and heats requirement,refining time to guarantee service life.

The LF and electric arc furnace refractory alumina magnesia carbon bricks made by CH refractories is resin bonded bricks containing high-purity fused and or sintered magnesia and flake graphite as their main ingredients.

Applications of Magnesia Carbon Brick:

●Steel ladles slag line and wall

●Widely used in converters, EAFs

Advantages of CH series Magnesia Carbon Brick:

●Good oxidation resistance due to use of high purity flake graphite.

●High temperature resistance and erosion resistance

●Free sample,Free construction guidance ,free 3D design

●Customerize mould according to different size requirements for free

|

Brands |

CH-MT-12A |

CH-MT-12B |

CH-MT-12C |

CH-MT-14A |

CH-MT-14B |

CH-MT-14C |

|

MgO/%≥ |

78 |

76 |

74 |

76 |

74 |

72 |

|

C/%≥ |

12 |

12 |

12 |

14 |

14 |

14 |

|

Apparent porosity/% ≤ |

4 |

5 |

6 |

4 |

5 |

6 |

|

Bulk density g/cm3 ≥ |

2.98 |

2.96 |

2.98 |

2.98 |

2.96 |

2.95 |

|

Crushing strength/Mpa ≥ |

40 |

40 |

40 |

40 |

40 |

35 |

|

Hot modulus of rupture(1450℃)/Mpa |

8 |

7 |

6 |

12 |

10 |

8 |

This series of high temperature kiln refractory high alumina bricks use special grade aluminum bauxite clinker as the main raw material, supplemented by special additives, high pressure forming and high temperature firing. Refractory bricks alumina has the characteristics of large heat storage capacity and small creep rate.

Lightweight thermal insulating castable is formulated with different types of lightweight aggregates, powders, binders and expansion agents. lightweight castable refractory is a good new type of refractory insulation materials and energy-saving materials.

CH Refractories manufactured casting powder is widely applied for both opening and protected CCM casting condition as well as molded casting . Our engineer will design each order of casting powder composition according to steel grade, casting speed, and other related casting condition.

If you need our products please write down any questions, we will reply as soon as possible.