High-quality magnesia brick is a product made of high-grade molding and high-temperature firing using first-grade magnesia and high-purity magnesia as raw materials. Magnesia refractory brick has excellent heat resistant and high resistance to alkali slag erosion.

High-quality magnesia brick is a product made of high-grade molding and high-temperature firing using first-grade magnesia and high-purity magnesia as raw materials. Magnesia refractory brick has excellent heat resistant and high resistance to alkali slag erosion.

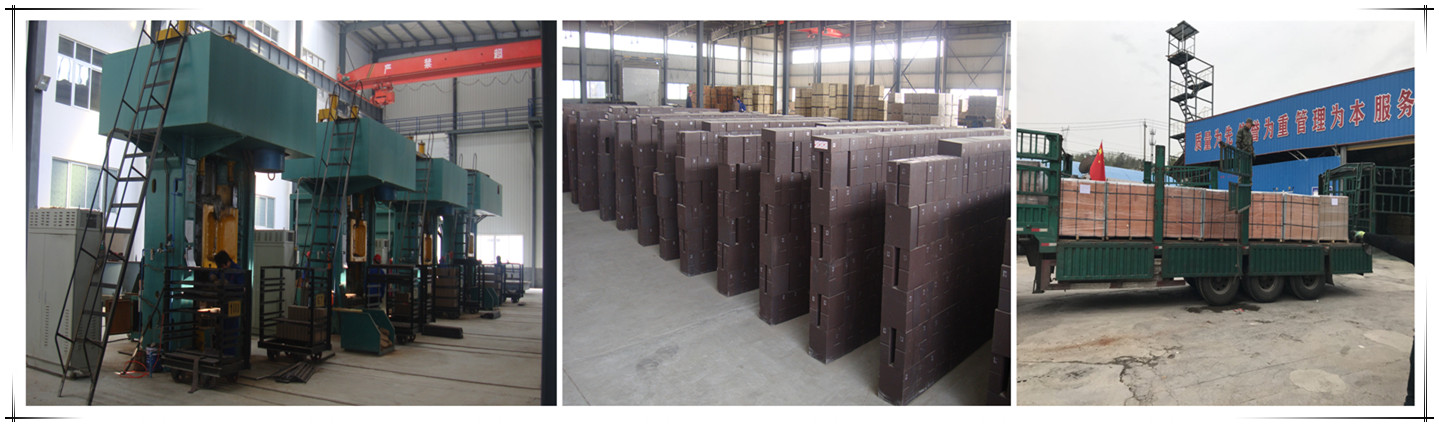

No matter standard size or special-shaped magnesite brick, CH Refractories provides customized magnesite refractories according to customers. We specialize in magnesium brick for years and we always treat each customers with sincere service.

Applications of Magnesia Brick:

●Glass Industry glass furnace regenerator checker

●Building field

●lime kiln,cement kiln

●Refractory field

●Calcination kiln,shaft kiln and tunnel kiln

●Non-ferrous metallurgical field

●Converter furnace and EAF

●Copper,nickel,lead,zinc,tin smelting furnace lining, refined copper

Advantagesof CH series Magnesia Brick:

●Strong resistance to metallurgical slag

●Free sample,Free construction guidance ,free 3D design

●Customerize mould according to different size requirements for free

|

Items |

CH-MZ-91 |

CH-MZ-93 |

CH-MZ-95 |

CH-MZ-97 |

|

Mgo% ≥ |

90 |

93 |

95 |

97 |

|

SiO2%≤ |

— |

— |

2.50 |

1.20 |

|

CaO%≤ |

3.0 |

2.50 |

2.0 |

1.50 |

|

Apparent porosity/%≤ |

20 |

18 |

18 |

18 |

|

CCS /MPa ≥ |

40 |

50 |

50 |

50 |

|

0.2 MPaRefractoriness Under Load/℃ |

1500 |

1550 |

1600 |

1650 |

CH Refractories manufactures different brands ladle nozzle and collector nozzle for various capacity ladle, which can meet different service life requirements.

Light weight fire clay brick is made of local top grade fireclay materials under the high temperature according to the lastest national standard. The temperature in the 1200-1400 ℃. Ingredients are mixed with water made of plastic material or mud, mud with extrusion or pouring shape, 1250-1350 ℃ after dry burning oxidation atmosphere.

CH refractories can design and produce argon purging and non-purging monoblock stopper as per the conditions of continuous casting processes in steel mills. The head of monoblock stopper can be Al2O3-C , MgO-C, Spinel-C or ZrO2-C based according to the types of steel to cast.

If you need our products please write down any questions, we will reply as soon as possible.