The manufacturing technique of phosphate refractory bricks is same as phosphate castable. With rapid development recent years, phosphate refractory brick is remarkably effective in cement kiln and electric furnace roof.

The manufacturing technique of phosphate refractory bricks is same as phosphate castable. With rapid development recent years, phosphate refractory brick is remarkably effective in cement kiln and electric furnace roof.

Advantages of Phosphate Refractory Brick

● Higher strength and good wear resistance.

● Good chemical resistance. (The alkali resistance is better than clay bricks and high alumina bricks)

●Good thermal shock resistance.

● The load softening temperature is higher.

● Customerize mould according to different size requirements for free

Application of Phosphate Refractory Brick:

Transition zone of the rotary kiln, the kiln mouth, the kiln door cover, the lining of the cooler and other parts of the refractory brick that are easy to loose and fall.

|

Brands |

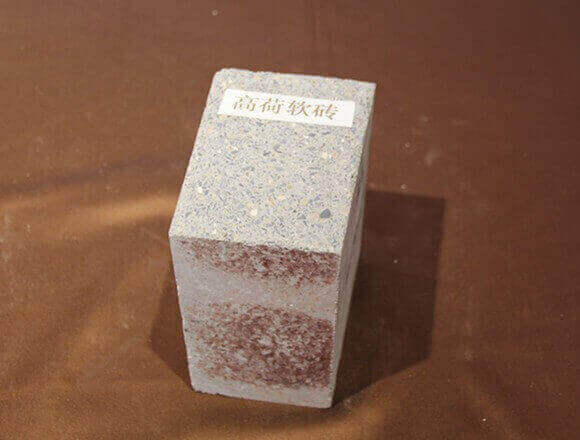

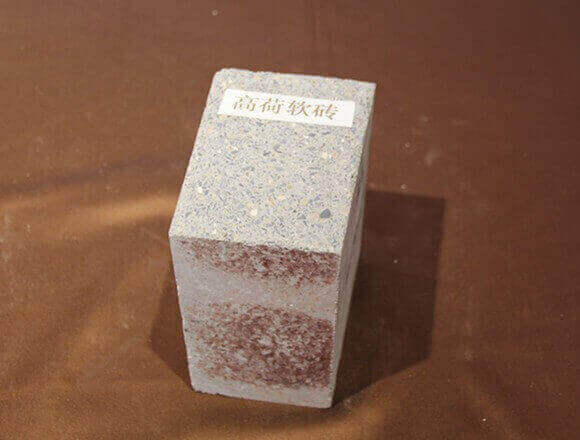

Ordinary phosphate brick |

Phosphate combined wear-resistant brick |

Special phosphate brick |

Phosphate composite brick |

|

|

Items |

CH-PZ75 |

CH-PA75 |

CH-PT80 |

Heavy part |

Lightweight part |

|

AL2O3 /% ≧ |

75 |

75 |

80 |

75 |

55 |

|

Fe2O3%≤ |

2.1 |

2.1 |

1.8 |

2 |

1.5 |

|

Refractoriness /℃ ≥ |

1770 |

1770 |

1790 |

1770 |

—- |

|

Bulk density (110℃×24h) g/cm3 ≥ |

2.7 |

2.75 |

2.9 |

2.8 |

1 |

|

Compressive strength/ MPa ≥ |

70 |

75 |

80 |

75 |

5.5 |

|

0.2Mpa refractoriness under load /℃≥ |

1350 |

1300 |

1520 |

1350 |

— |

|

Thermal shock resistance(1100℃)/time |

20 |

20 |

15 |

—- |

—– |

Various types of ventilated bricks(ladle Porous plug) such as through-hole type, directional slit type, directional labyrinth type, internal integral type and external split type can be designed and manufactured according to user requirements, and the matching ventilation block locking mechanism can be designed according to user requirements.

EAF tap-hole filler is developed with magnesite, forsterite and silica as the main materials according to different requirements, and shows the features of easy installation, good sintering, floating resistance, high self-open rate and good safety performance.

Wear-resistant plastic, which is made of special grade alumina, mullite, corundum, siliconcarbide as aggregate and matrix material, mixed by adding binder, additive and plasticizer.

If you need our products please write down any questions, we will reply as soon as possible.