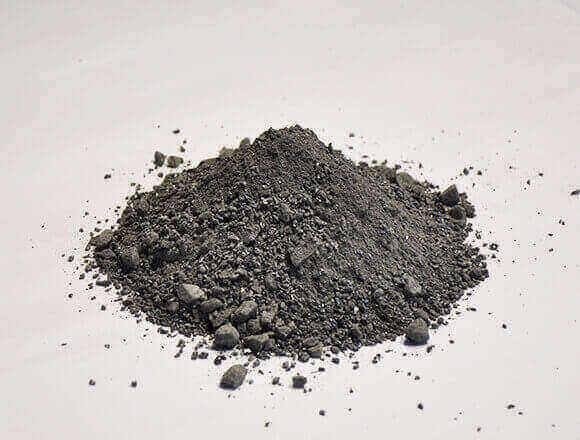

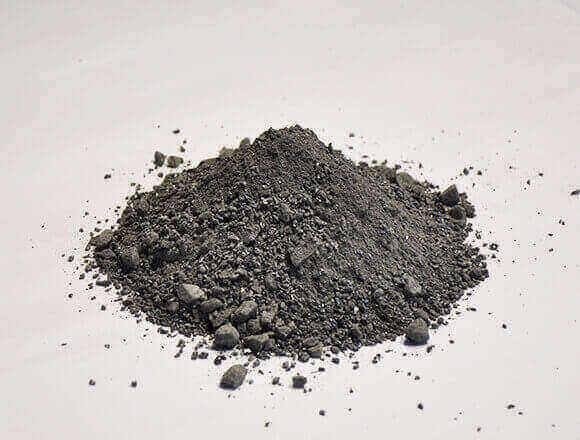

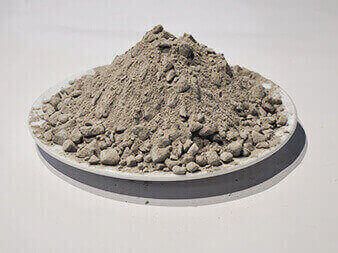

High-strength wear-resistant plastic refers to a mixture of high-grade refractory materials such as corundum, mullite or silicon carbide, and a binder and an admixture (anti-shrinkage agent, preservative, antifreeze).

High-strength wear-resistant plastic refers to a mixture of high-grade refractory materials such as corundum, mullite or silicon carbide, and a binder and an admixture (anti-shrinkage agent, preservative, antifreeze).

The high-strength wear-resistant plastic is a semi-wet mud material. When it is applied, water or aluminum dihydrogen phosphate or other liquid is mixed into a mud material, which is pressed or extruded into a block material having a certain plasticity. When thehammer is hit, the plastic is deformed without cracking or slumping, and the deformedshape can be maintained after the external force is released.

High-strength wear-resistant plastic is divided into corundum-mullite refractory plastic (GNS-65\GMS-75\GMS-85)\carburized wear-resistant plastic (TS60\TS-70) according to the material. Medium grade. G stands for corundum, M stands for mullite, T stands for silicon

carbide, and S stands for plastic. The number after the letter represents the percentageof the main material.

|

Items |

Corundum-mullite |

Silicon carbide |

|||

|

/ |

GMS-65 |

GMS-75 |

GMS-85 |

TS-60 |

TS-70 |

|

AL2O3% ≥ |

65 |

75 |

85 |

— |

— |

|

SiC % ≥ |

— |

— |

— |

60 |

70 |

|

Bulk density 110℃×24h (dry) g/cm3 ≥ |

2.5 |

2.7 |

2.8 |

2.4 |

2.6 |

|

Compressive strength/ MPa 850℃×3h(after firing) ≥ |

70 |

80 |

90 |

60 |

70 |

|

Normal wear850℃×3h (after firing) cm3≤ |

7 |

6+ |

5 |

6 |

5 |

|

PLC /% (850℃×3h) ≤ |

-0.4~0 |

-0.5~0 |

-0.5~0 |

-0.5~0 |

-0.6~0 |

|

Thermal shock stability (850℃×3h after firing) time≥ |

30 |

30 |

25 |

35 |

40 |

|

Plasticity index % |

15~40 |

||||

Al2O3-SiC Castable for Metal Mixer is developed with high quality bauxite, corundum and SiC as the main raw materials, and bonded by low cement or ultra-low cement.

High temperature fired slide gate plates developed by Zhengzhou Caihua are produced via high speed mixing, high pressure pressing, high temperature firing, vacuum and pressurized pitch impregnation, precise surface grinding and hot stainless steel looping processes. Fired slide gate plates have low impurity and are stable on quality.

The alkali-resistant firebricks use silica, coke stones and appropriate additives to improve the microstructure of the product.

If you need our products please write down any questions, we will reply as soon as possible.