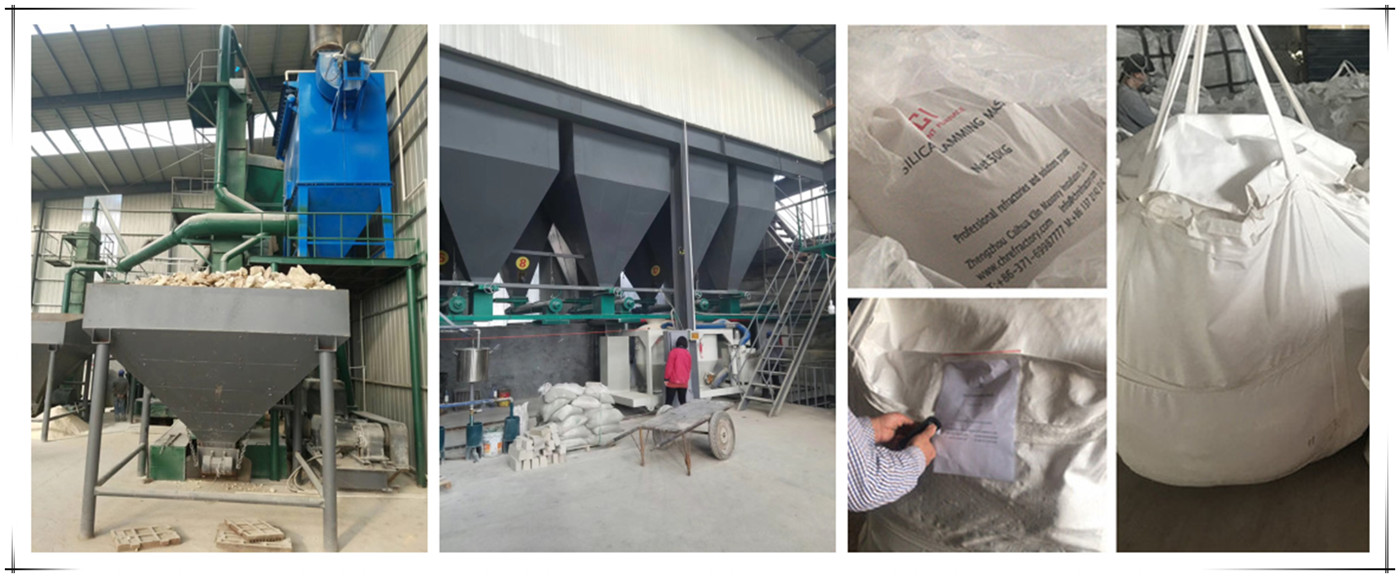

There are mainly four refractory materials for furnace in CH Refractories, which are pre-mix silica ramming mass and neutral ramming mass for induction furnace, magnesia refractory mix for EAF bottom, and Electro-fused AZS refractory ramming mass for glass kiln.

There are mainly four refractory materials for furnace in CH Refractories, which are pre-mix silica ramming mass and neutral ramming mass for induction furnace, magnesia refractory mix for EAF bottom, and Electro-fused AZS refractory ramming mass for glass kiln.

Silica ramming mass for Induction furnace:

Silica ramming mass, also known as acidic ramming mass or quartzite powder or quartz powder, which is premixed ramming mass. Silica ramming mass is a ramming material which can be used for furnace lining of coreless induction furnaces for melting of scrap to liquid steel. Silica ramming mix is a dry induction furnace refractories that can be used for all types of iron, steel, aluminium and foundries.

The raw material of silica ramming mass is high quality quartz, mixed with high quality boric acid. Silica content of its raw material is more than 99%. Generally we will add 1.5 % to 1.8 % boric acid to premix with quartz, but it can be changed as per customers’ requirements. In order to achieve the best performance, we will design different sizes for customers according to different capacity of induction furnace.

Generally, the service life is 20-40 heats according to different casting condition and steel grade.

|

Brand |

SiO2 |

H3BO3 |

Fe2O3 |

H2O |

Size |

Refractoriess |

|

Index |

≥98.5% |

1.5-1.8% |

≤0.018 |

≤0.1 |

0-20mm |

1750℃ |

Induction Furnace Neutral Ramming Mass:

Induction furnace neutral ramming mass is a cost-effective dry vibrating refractories composed of special grade clinker clinker, corundum, spinel, magnesia and sintering agent. Such ramming mass is suitable for the melting of carbon steel, alloy steel, stainless steel and high manganese steel, with high service life and high cost performance. Induction furnace neutral ramming mass is used by many foundry companies and steel plants because of achieving low cost and long life with good performance.

Advantages of Induction Furnace Neutral Ramming Mass:

When using ramming mix in induction furnace, the neutral ramming mass performs much longer service life comparing with silica ramming mass, which can save much labor time and furnace baking time, thus can save much money for steel plants.

• Additives a, longer and stable service life to get high efficiency

• Easy to be installed and maintenance, saving time and labor cost

|

Material |

Bauxite-spinel |

|

AL2O3/% |

≥72 |

|

MgO,% |

≥18 |

|

Bulk density g/cm3 |

≥2.8 |

|

Normal use temperature/℃ |

1600~1650 |

|

Use upper temperature limit (short time)/℃ |

1700 |

|

Maximum granularity/mm |

5 |

Magnesia ramming mass for EAF bottom:

Dry refractory rammmg mix for EAF bottom is made from high quality magnesite and Fe2O3-CaO magnesite, and shows the features of excellent resistance against steel penetration, superior erosion resistance, easily-sintering, high bulk density and easy installation. Dry rammmg mix for EAF bottom is ideal choice for HP/UHP EAF bottom.

Advantages of magnesia rammmg mix for EAF bottom:

Dry ramming mass for EAF bottom is dry refractories, so it is easy to be constructed on work site, and ready to be used after construction done. Dry rammmg mix for EAF bottom largely improves the efficiency and extends the service life as well without baking.

|

Brand |

CH-DLD85 |

CH-DLD80 |

CH-DLD68 |

|

MgO/% |

≥85 |

≥80 |

≥68 |

|

CaO/% |

6-8 |

6-9 |

18-25 |

|

Fe2O3/% |

4~5 |

5~9 |

3~5 |

|

SiO2/% |

≦1.5 |

≦1.5 |

≦1.5 |

|

Cold crushing strength/ MPa

|

≥10 (1300°C , 3h) |

≥10 (1300°C , 3h) |

≥10 (1300°C , 3h) |

|

≥30 (1600°C , 3h) |

≥30 (1600°C , 3h) |

≥30 (1600°C , 3h) |

|

|

Bulk density/g·cm3

|

≥2.45 (1600°C , 3h) |

≥2.45 (1600°C , 3h) |

≥2.40(1600°C , 3h) |

Electro-fused AZS ramming mass for glass kiln:

Electro-fused AZS ramming mass is monolithic refractories and electro-fused AZS ramming mass is composed of molten corundum aggregate particles and a small amount of additives. Electro-fused AZS ramming mass is prepared by using high-quality zirconium aggregate, powder material, aluminum phosphate as binder and admixture, which has low thermal conductivity, good thermal shock resistance, chemical stability and melting. Glass and liquid metal have good corrosion resistance, work stability under oxidizing atmosphere, and do not chemically react with molten metal. Electro-fused AZS ramming mass is an excellent thermosetting ramming mix with reasonable price.

Advantages of Electro-fused AZS Ramming Mass:

● convenient for use

● small thermal expansion and shrinkage

● strong resistance to solution corrosion.

● hardening at normal temperature, high compressive strength in high temperature

Applications of Electro-fused AZS Ramming Mass:

●Sealing layer of glass and frit bath kiln.

●Used in the field of glass furnace kiln, ladle and circulating fluidized bedboiler.

|

Items |

Electro-fused AZS ramming mass |

|

ZrO2 % ≥ |

28 |

|

Bulk density g/cm3 ≥

|

2.9 |

|

Normal temperature compressive strength MPa 110℃drying ≥

|

50 |

|

Refractoriness /℃ ≥ |

1770 |

|

Maximum Service temperature/℃ |

1650 |

|

Use density kg/m3 |

3000 |

The submerged entry nozzle continuous casting protects the liquid steel from being oxidized by the ambient air when it flows into the crystallizer from the tundish.

Light weight high alumina brick is also named high-aluminium heat insulation brick, are used in building heat insulating walls or heat preserving walls, which is basically for preserving or insulation heat. Refractory insulation thermal brick contains more than 48% alumina oxide.

High-quality magnesia brick is a product made of high-grade molding and high-temperature firing using first-grade magnesia and high-purity magnesia as raw materials. Magnesia refractory brick has excellent heat resistant and high resistance to alkali slag erosion.

If you need our products please write down any questions, we will reply as soon as possible.