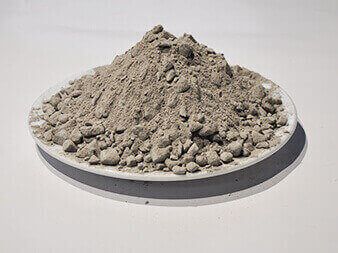

The heat resistant refractory cement also well known as calcium aluminate cements, and high alumina castable refractory cement. Generally there are 4 grades of refractory cement according to Al2O3 content, A600, A700,A900 and CA-70.

The heat resistant refractory cement also well known as calcium aluminate cements, and high alumina castable refractory cement. Generally there are 4 grades of refractory cement according to Al2O3 content, A600, A700,A900 and CA-70. The heat resistance cement can be used for making refractory castable.

CH Refractories with 500T manufacturing capacity of refractory alumina cement one day to make sure delivery to customers in time. The refractory aluminum cement will be packaged into two layers moistureproof polytene bags directly from the manufacturing line to protect high temp refractory cement from wet air.

As professional manufacturer and company of refractory aluminate cement since 1980, CH refractories company produces and provides customers with a varied range of high-tech calcium aluminate solutions benefiting from the highest performance and quality. The SECAR range offers a large choice of binders based on calcium aluminate technology for fire proof applications. Through its understanding of the customer’s needs, CH refractories company has developed one of the widest ranges of aluminate cement for sale on the market.

Applications of Refractory Cement:

High alumina cement is mainly used to configure refractory castable such as high alumina low cement castable which can build or repair furnace or kiln for heat insulation or high temperature erosion.

Advantages of CH series Refractory Cement:

●Fast setting at high temperature

●Increase castable strength

●Can replace castable when using

●Can be added to both heavy and light castable

● Biological acid erosion

● High temperature resistance

●Sulfate corrosion resistance

|

Brand |

A600 |

A700 |

A900 |

CA-70 |

|

|

Chemical Composition (%)

|

Al2O3 |

≥50 |

≥51 |

≥53.5 |

68.5-70.5 |

|

SiO2 |

≤7.8 |

≤7.5 |

≤5.5 |

≤0.5 |

|

|

Fe2O3 |

≤2.5 |

≤2.5 |

≤2.5 |

≤0.2 |

|

|

CaO |

/ |

/ |

/ |

28.5-30.5 |

|

|

MgO |

/ |

/ |

/ |

≤0.4 |

|

|

R2O |

≤0.4 |

≤0.4 |

≤0.4 |

≤0.4 |

|

|

S |

≤0.1 |

≤0.1 |

≤0.1 |

/ |

|

|

Cl |

≤0.1 |

≤0.1 |

≤0.1 |

/ |

|

|

325 mesh residue on sieve(%) |

≤15 |

≤12 |

≤8 |

/ |

|

|

d50(μm) |

/ |

/ |

/ |

11-14 |

|

|

-45μm(%) |

/ |

/ |

/ |

≤8.0 |

|

|

Specific Surface (m2/kg) |

≥300 |

≥320 |

≥350 |

/ |

|

|

Setting time(h:min)

|

Initial setting (min) |

≥45 |

≥60 |

≥90 |

120-180 |

|

Final Setting (min) |

≤6 |

≤6 |

≤6 |

150-240 |

|

|

Cold Modulus of Rupture (MPa)

|

24 hour |

≥6 |

≥6.5 |

≥8 |

7.5-10 |

|

72 hour |

≥7 |

≥7.5 |

≥10 |

10-12 |

|

|

Cold Crushing Strength (Mpa)

|

24hour |

≥45 |

≥55 |

≥72 |

40-50 |

|

72hour |

≥55 |

≥65 |

≥82 |

45-55 |

|

High alumina castable is a kind of refractory castable which uses high alumina raw materials as aggregates and the powder and then be added with binding agent. High aluminum castable refractories has high mechanical strength, good thermal shock resistance, good corrosion resistance.

The ladle shroud is a refractory material which connects the steel ladle with the tundish. The ladle shroud has the functions of stabilizing the flow state of liquid steel, preventing liquid steel from oxygenation and splashing.

High-quality magnesia brick is a product made of high-grade molding and high-temperature firing using first-grade magnesia and high-purity magnesia as raw materials. Magnesia refractory brick has excellent heat resistant and high resistance to alkali slag erosion.

If you need our products please write down any questions, we will reply as soon as possible.