Zircon refractory ramming material is made of high-quality zircon sand aggregate, powder, aluminum phosphate as binder and admixture, and has the best ratio of thermal conductivity and thermal shock resistance.

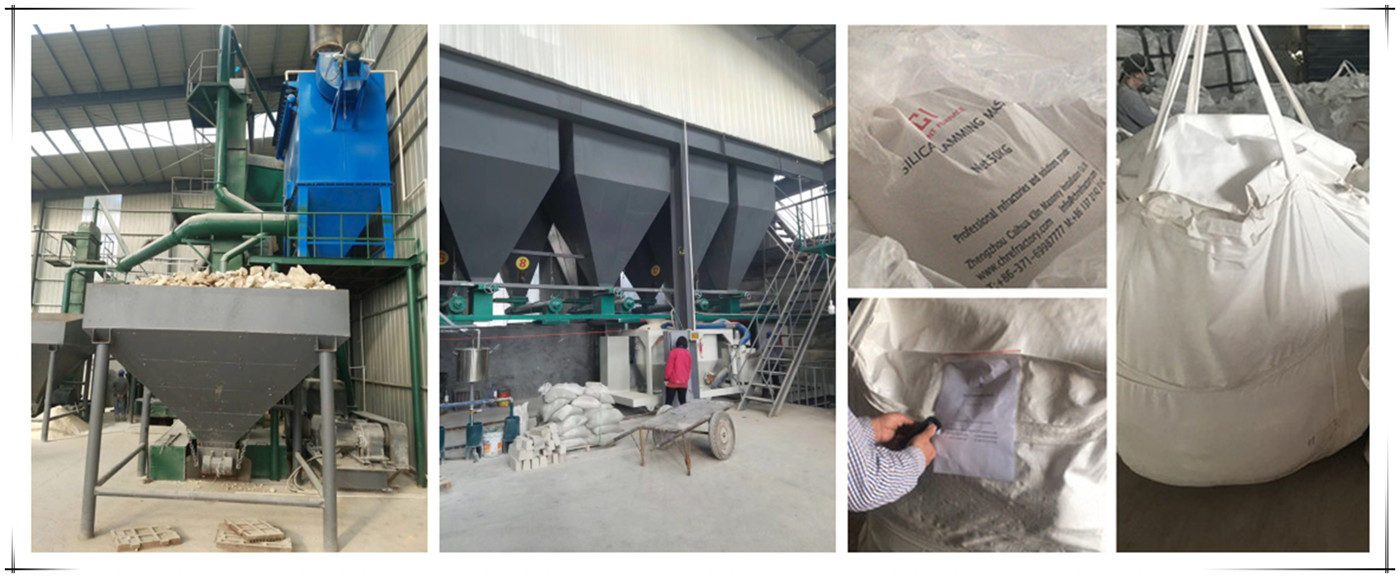

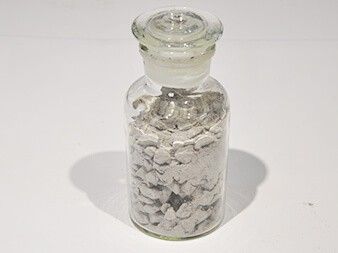

Zircon refractory ramming material is made of high-quality zircon sand aggregate, powder, aluminum phosphate as binder and admixture, and has the best ratio of thermal conductivity and thermal shock resistance. Molten glass and liquid metal have good corrosion resistance, work stably under oxidizing atmosphere, and do not react with molten metal. Zircon ramming mix is widely used in glass furnace kiln bottom, ladle and circulating fluidized bed boilers.

|

Item |

Zircon ramming mass |

|

ZrO2 % ≥ |

60 |

|

Bulk density g/cm3 ≥ |

3.5 |

|

Normal temperature compressive strength /MPa (110℃drying ) ≥ |

45 |

|

Refractoriness ℃ ≥ |

1790 |

|

Maximum service temperature ℃ |

1650 |

|

Use density kg/m3 |

3600 |

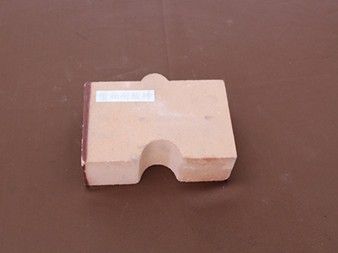

The acid-resistant refractory bricks produced by our company adopt high-grade refractory aggregates, powders, additives, etc. After reasonable grading and high-temperature firing, they can fully meet the acid and high temperature resistance of furnace lining refractories under various acid regeneration process conditions.

Dry anti-seepage refractories works well with simple construction, good thermal insulation effect and strong anti-permeability. The working principle of Dry anti-seepage refractory material is to react alkali ions in materials and metal liquids at high temperature, form isolation layer on the surface, prevent sodium salt from going to cathode block.

This product has high thermal strength, strong wear resistance, excellent corrosion resistance and high temperature volume stability, effectively extending the service life of CFGboilers. Can be used for the wear lining of various CFB boilers.

If you need our products please write down any questions, we will reply as soon as possible.