Calcium Oxide Products

Calcium oxide products have good high temperature performance and strong resistance to alkaline slag erosion, is a very good refractory, but the only disadvantage is easy to produce hydration reaction. Calcium oxide reacts with water to form calcium hydroxide, resulting in volumetric expansion during hydration. Although it is very difficult to solve the problem of anti-hydration of calcium oxide products, the production and application of calcium oxide products are still improving and developing.

Calcium oxide is also very difficult to sinter oxide raw materials. The hydration of calcium oxide can not be eliminated by high purity electric fused calcium oxide. Adding some oxides into the raw materials of calcium oxide can promote sintering and reduce the hydration rate. For example, if 2%~12% titanium dioxide is added into calcium oxide, it can be sintered at 1770℃. The main crystal phase is CaO, while the secondary crystal phase is 3CaO·2TiO2 and 4CaO·3TiO2. The products made by adding 2.5%~5.0%Cr2O3 and 2.5%~5.0% bentonite in the calcium oxide can significantly improve the hydration resistance.

Mud casting molding products: calcium hydroxide [Ca(OH)2] is made by fully hydration of high purity calcium oxide raw materials, and then roasted at 1000℃ for 1h. After firing, it is crushed to a particle size less than 275 mesh, and then it is finely ground for 24h by adding wine in the porcelain ball grinding tank. The material: ball: alcohol is 1:2:0.75.

The blank body was dried in a vacuum drying oven, then directly put into a high temperature furnace at 200℃, and heated at the heating rate of 150~200℃/h to 1000℃ for 2h pre-burning, after cooling, the blank was repaired and shaped, and then burned in a vacuum medium frequency furnace at 1850℃ for 30min. Burned calcium oxide products or crucible should be stored in a dryer to prevent hydration.

The high purity calcium oxide raw materials (CaO ≥ 99%) were finely crushed and processed into a particle size less than 0.25mm. After adding an appropriate amount of anhydrous calcium chloride, the material was mixed and ground in the ball mill for 3h. In an argon - protected molybdenum wire furnace, the material is heated at 1650℃ for 4 hours. The clinker was then crushed to a size of 2~0.1mm for aggregate and stored in a dryer.

The aggregate of calcium oxide clinker and fine powder are mixed proportionally and formed in isostatic press with rubber mould.

The product is fired in a hydrogen protected induction furnace at 1850℃ for 3.5h, or in a high-temperature kiln at 1800℃ for 8h.

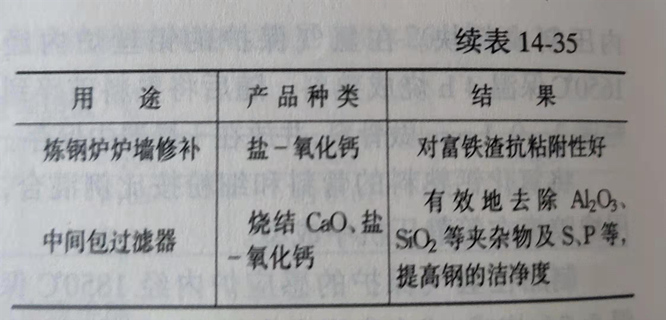

The physical and chemical properties of calcium oxide clinker sand obtained by sintering or electrofusion are shown in table 14-28.

The calcium oxide clinker produced by the above two methods can be used to produce calcium oxide light fired brick, fired brick and fired oil-immersed brick.

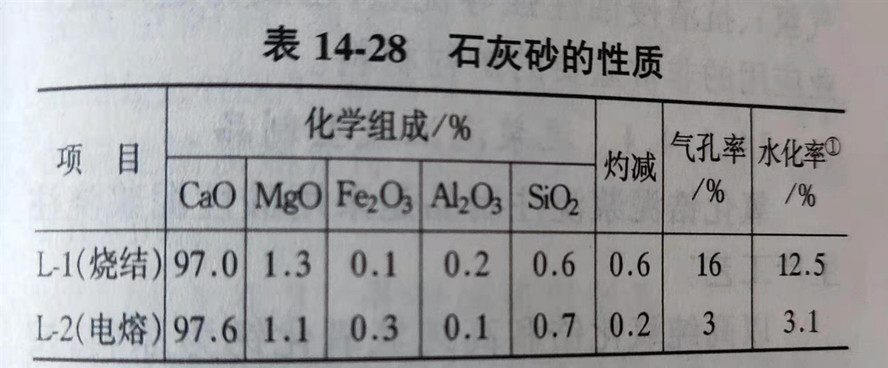

The physical and chemical properties of calcium oxide crucible are shown in table 14-29.

The physical and chemical properties of isostatic pressed calcium oxide crucible developed by ustb are shown in table 14-30.

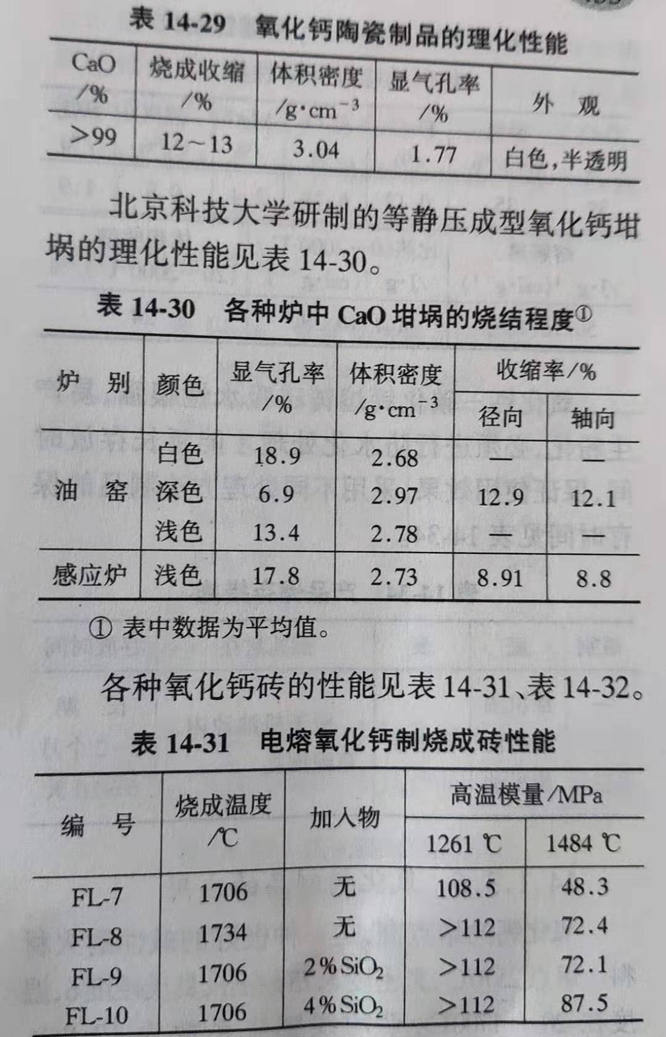

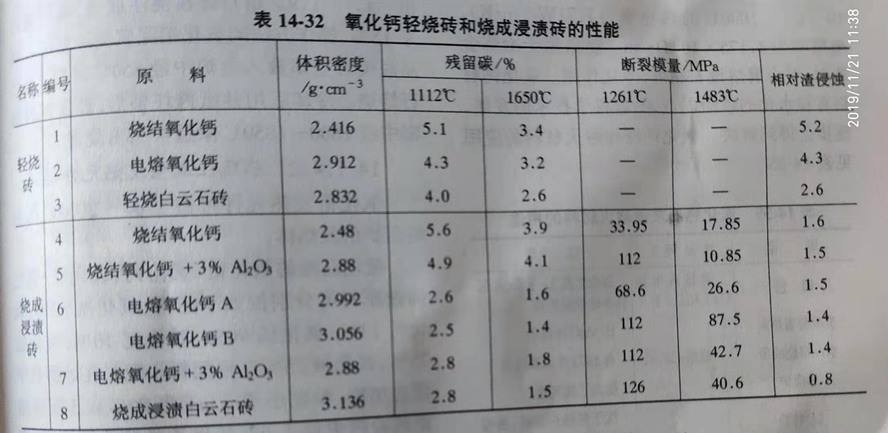

The properties of various calcium oxide bricks are shown in table 14-31 and table 14-32.

Calcium oxide-silicon carbide fused brick has resistance to high alkalinity, high fluorine and high rare-earth slag erosion, and is suitable for smelting rare-earth alloy refractories.

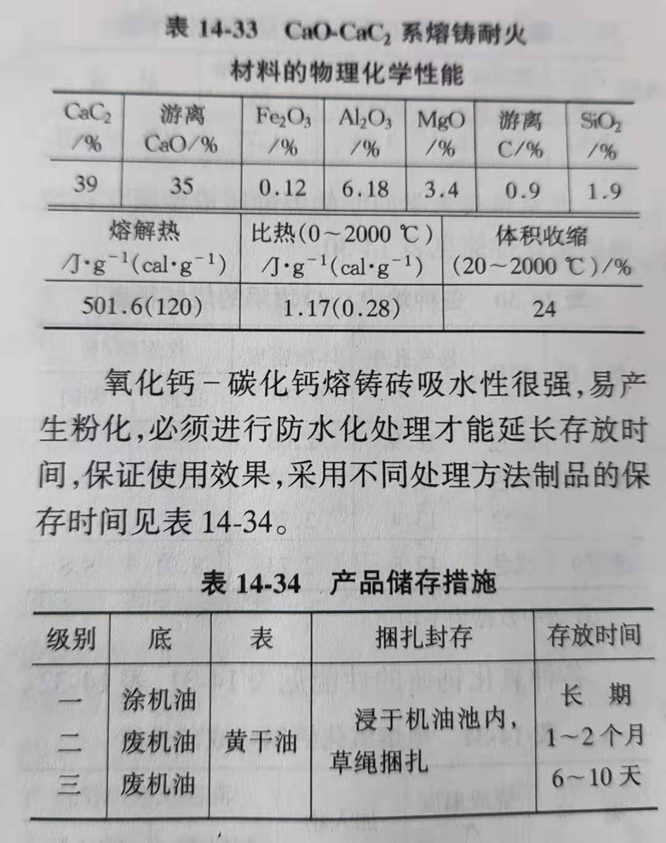

Using limestone and coke as raw materials, the bricks were cast by electric melting. The physical and chemical properties of the cast brick are shown in table 14-33.

The calcium-carbide fused brick has a strong water absorption and is easy to powder, so the waterproof treatment must be ensured to prolong the storage time and ensure the use effect. The storage time of products with different treatment methods is shown in table 14-34.

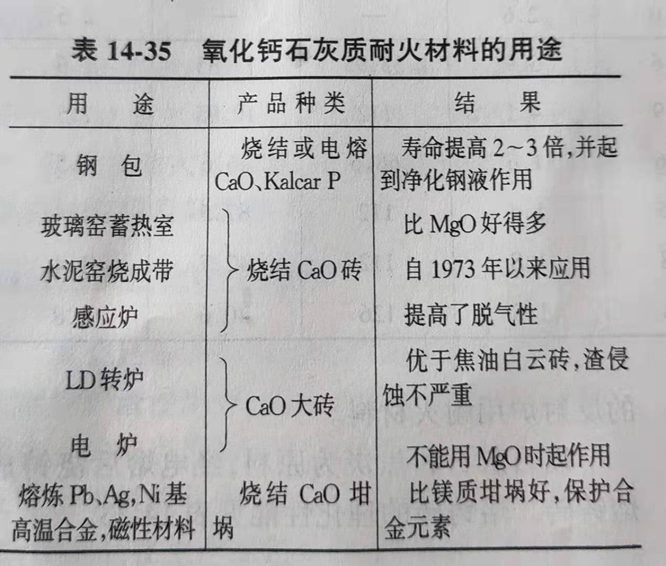

Calcium oxide has a high melting point and is an excellent alkaline refractory. Melting point 2570 ℃, true density of 3.75 g/cm3, mohs hardness 6, the temperature in the 20 ~ 1700 ℃, the average linear expansion coefficient of 13.8 x 10-6 ℃ - 1100 0 ℃ thermal conductivity is 7.71 W/(m, K), the resistivity of 4.175 x 106 Ω · cm. When the product is used for smelting metal, it can refine and purify the molten metal. Calcium oxide material has the fatal weakness of easy hydration, with the development of science and technology, will be gradually solved. Application of calcium oxide special refractories is shown in table 14-35.