Nitride Bonded Silicon Carbide Products

Nitride bonded silicon carbide products are high grade SiC refractory with single phase or complex phase nitrides such as Si3N4, Sialon, Si2N2O and AlN as the bonding phase. At present, Si3N4 combination, Sialon combination, Si2N2O combination and Si3N4/Sialon, Si3N4/Si2N2O complex combination SiC products have been industrial applications.

In 1955, Carborundum corporation of the United States first developed Si3N4 bonded SiC material based on oxide bonded SiC. In the early 1960s, Si2N2O combined SiC materials were successfully developed abroad, and Sialon/Si3N4 and Sialon combined SiC refractory materials were successfully developed in the 1980s. China began to carry out nitride bonded SiC research work in 1984, successively by the former ministry of metallurgy iron and steel research institute and luoyang refractories research institute first developed Si3N4 bonded SiC products, respectively used in the blast furnace hearth and tuyere cover. In 1985, Si3N4 combined with SiC brick independently developed and produced in China was applied to no.6 blast furnace of anshan iron and steel for the first time and achieved success. In 1986, the tuyere sleeve brick developed by luoyang refractories research institute was compared with Japanese products in baosteel no.1 blast furnace, and its comprehensive performance was better than imported products, and began to replace imported products. In 1990, luoyang refractories research institute first developed Sialon combined SiC brick for blast furnace in China, which was successfully used in no.4 blast furnace of anshan iron & steel co., LTD. Up to 1992, China has built a number of Si3N4 combined SiC product production lines, the national production capacity of 3300tSi3N4 combined SiC products. After more than 20 years of research and development, China has become the main producer of Si3N4 combined SiC products in the world. The annual production capacity of Si3N4 (Sialon or Si2N2O) combined SiC products is estimated at more than 35,000 t. Luoyang refractories research institute of sinosteel group has built a production line of Si3N4 (Sialon or Si2N2O) combined with SiC products with an annual output of 15,000 t, ranking first in Asia in terms of production capacity and scale. The quality and level of Si3N4 combined with SiC products Sicatec75 are among the international advanced levels. At present, Sicatec75 accounts for 40% of the market share of Si3N4 combined with SiC products for aluminum electrolysis cells in the world.

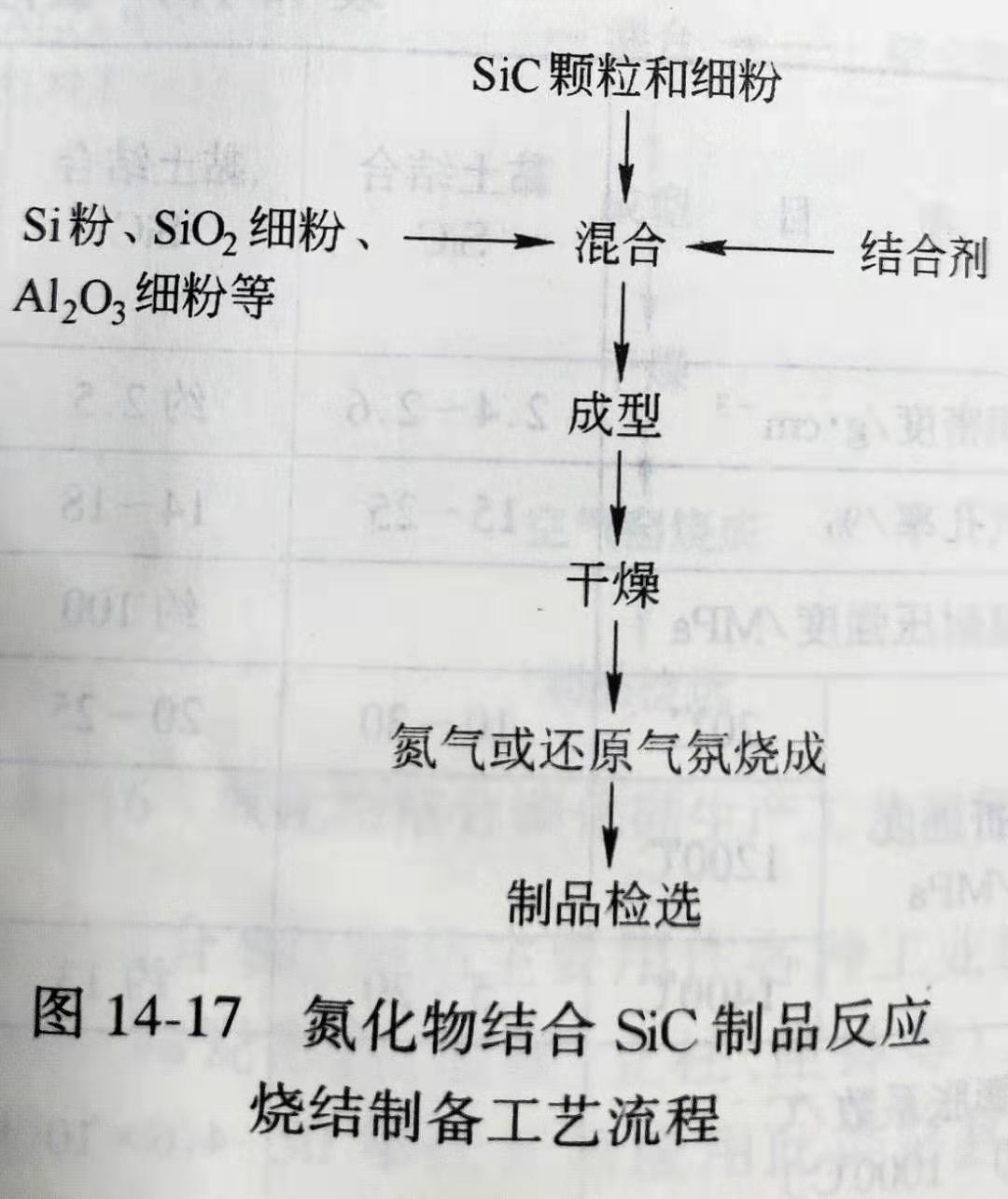

Covalent bond compounds such as Si3N4, Sialon and Si2N2O are engineering ceramic materials with excellent performance. These synthetic materials can only be sintered well under high temperature inert or neutral atmosphere conditions. At present, Si3N4, Sialon and Si2N2O synthesis materials are directly used as bonding materials to prepare and produce nitride bonded SiC refractories, which cannot be popularized in practice due to high production costs. Nitride bonded SiC products are basically prepared by reaction sintering. The process principle is as follows: a certain amount of Si powder, Si powder, SiO2 fine powder or Si powder, Al2O3 fine powder and the additive are added to the industrial SiC materials with a certain particle size. After mixing and forming, the reaction sintering is carried out at 1400~1600℃ in a high purity N2 atmosphere. During the sintering process, the following chemical reactions will occur:

3Si+2N2→Si3N4

3Si+SiO2+2N2→2Si2N2O

Si3N4+SiO2→2Si2N2O

(6-Z)Si3N4+Z(Al2O3+AlN)→3Si6-zAlzOzN8-z

The Si3N4, Si2N2O or Sialon generated by the reaction firmly combine SiC particles, endowing the products with various excellent properties. The production process is shown in figure 14-17.

Nitride combined with SiC products adhering to the nitrides and many excellent properties of the SiC materials, with high temperature and high strength, thermal conductivity, small linear expansion coefficient, good thermal shock resistance, good resistance to alkali erosion, good oxidation resistance, zinc aluminum copper lead molten liquid such as erosion resistance ability and high temperature wear resistance is good wait for a variety of excellent performance, in the iron and steel, nonferrous metallurgy, ceramics and other industries widely used. Due to the different conditions of Si3N4, Si2N2O and Sialon, the microstructure and properties of various nitride bonded SiC materials are different, so the matching can be selected reasonably according to the actual conditions.

Si3N4 bonded SiC products are the products with the largest amount of nitride bonded SiC materials at present, which are mainly used as the lining of the middle part of the blast furnace (under the furnace body, the furnace waist and the furnace belly), the lining of aluminum electrolyzer and the kiln tools of various industrial furnaces. Sialon combined with SiC is mainly used as the lining of the waist or belly of the blast furnace. Si2N2O combined with SiC has been used as the lining of blast furnace in the past, but the amount is small. Si2N2O combined with SiC brick is no longer used in blast furnace, and Si2N2O combined with SiC is mainly used as ceramic kiln. At present, the consumption of Sialon combined SiC and Si2N2O combined SiC bricks will increase, and the consumption of Si2N2O combined SiC kiln furniture products will also increase.

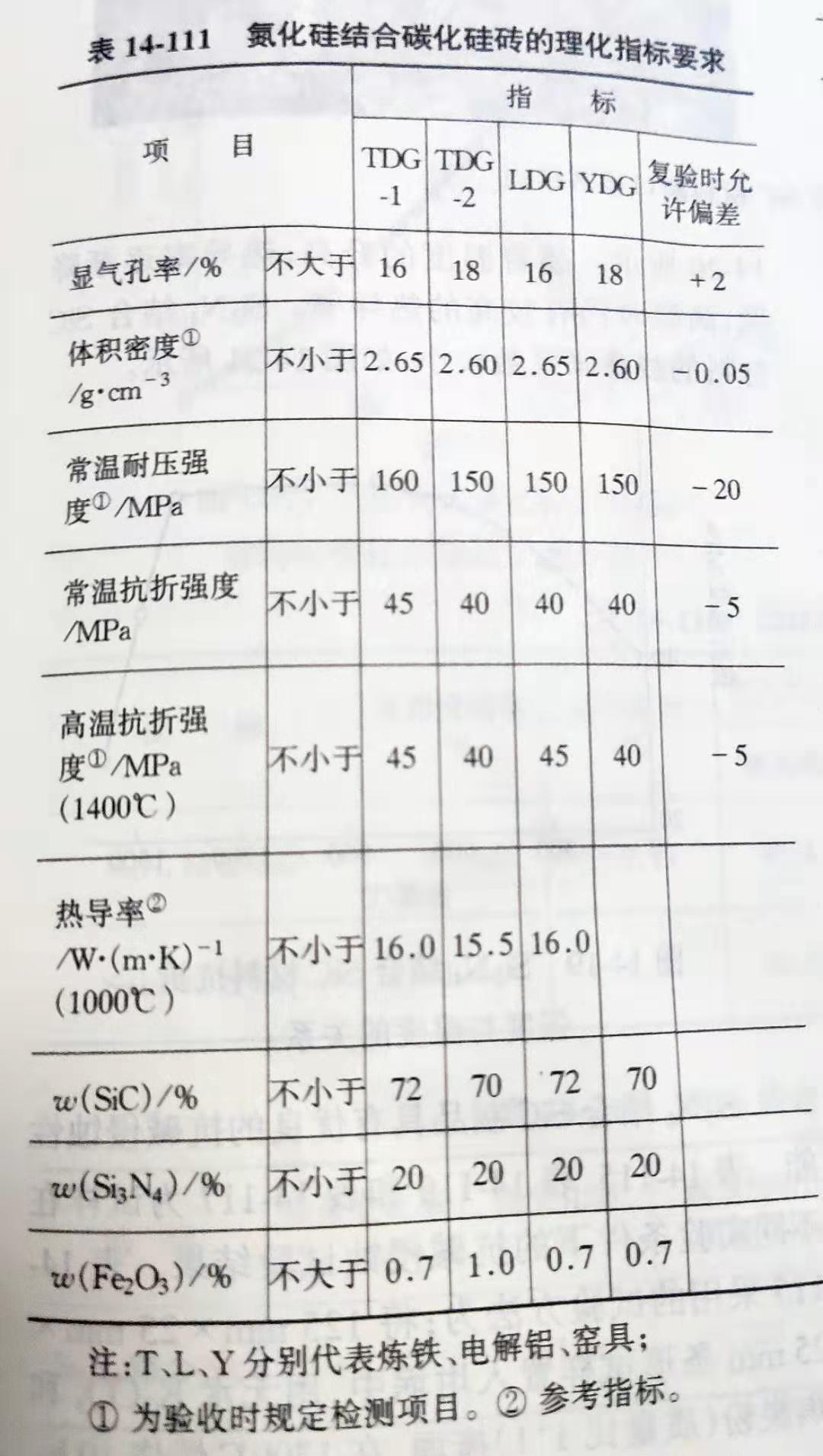

Given nitrides in combination with the rapid growth of the dosage of SiC products and production technology progress, our country revises refractory standardization technology committee has approved the new journal of silicon nitride combined with carborundum brick industry standard, the new formulation and passed "theron combined with refractory products industry standards (YB/T1427-2005), the two new standard has been implemented, the new standard for product physical and chemical performance index requirements are shown in table 14 table 14-11, 12.

A great deal of research has been done on the properties, production technology and application technology of nitride bonded SiC materials for blast furnace, aluminum electrolytic cell lining, kiln and other industrial applications, laying a good foundation for the application and development of nitride bonded SiC materials.