Steel Fiber Reinforced Refractory Castable

The heat resistant steel fiber of a certain size (about 20~35mm in length and 0.13~0.2cm2 in section area) is added to the castable refractory material in the mixture composed of refractory aggregate, binder and admixture, which is called the steel fiber reinforced refractory castable. Compared with the castable of unheated heat-resistant steel fiber, this castable has the following characteristics:

(1) the shrinkage of the castable material can be inhibited during curing, baking and high-temperature use;

(2) improve the toughness, mechanical impact resistance and mechanical strength of the castable;

(3) improve the thermal shock resistance of castable;

(4) prevent microcracks in the castable from breaking or spalling due to expansion or extension under thermal stress and mechanical stress.

The appearance size, cross section shape and addition amount of heat-resistant steel fiber used for reinforcing castable have influence on the reinforcing effect. The shape of the fiber is linear, wavy, serrated, stapled, etc. The cross section shape of the fiber is circular, square, diamond, crescent, etc. At present, the cross section is usually crescent shaped (straight fiber produced by melt extraction method), which can increase the contact area between steel fiber and castable matrix and increase the friction force, without affecting the mixing and stirring performance, and is easy to be evenly dispersed in the castable matrix.

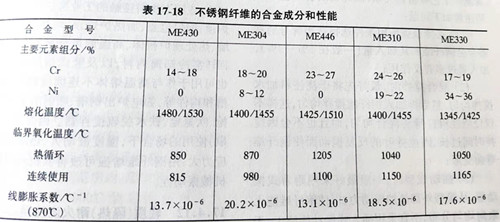

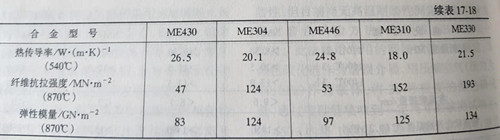

Now for the heat-resistant steel fiber reinforced refractory castable material and variety is more, but only 5 kinds of brands, is widely used in the alloy composition and properties are shown in table 17-18. Generally under 1000 ℃, the one-side heated castable lining body is ME304 and ME430 brand of stainless steel fiber reinforcement, and above 1000 ℃, is the ME446, ME310 and ME - 330 brand heat resistant stainless steel micro enhancement.

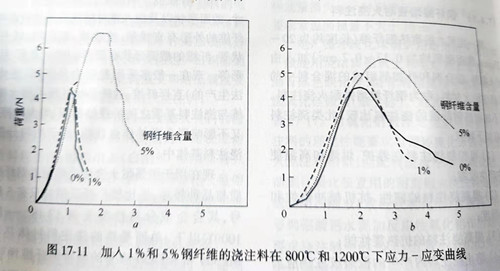

The main function of steel fiber reinforced castable is to improve the strain performance under stress, so as to improve the toughness, mechanical strength and thermal shock resistance of the castable liner. FIG. 17-11 shows the stress-strain characteristic curves at 800℃ and 1200℃ when different amounts of ME430 stainless steel fibers are added to the aluminum-silicon castable containing 33% Al2O3 and 53% SiO2. It can be seen that adding 5% steel fiber can significantly improve its mechanical strength and strain, with toughening effect.

The application effect of steel fiber reinforced castable liner is also closely related to its manufacturing process, so the following problems must be paid attention to in the preparation process:

(1) it is necessary to select the appropriate grade of high temperature alloy steel fiber and its addition amount (generally 1%~3%) according to the conditions of use.

(2) when mixing and stirring, it is best to mix the dry castable with water first, and then add the steel fiber to stir evenly, which not only makes the castable itself easy to mix evenly, but also won't cause the steel fiber to bend and deform due to too long stirring time and repeated agitation of the stirring blade;

(3) during the vibration molding, it is generally better to use the attached vibrator and apply the vibration force from the outside of the model, so that the steel fiber can be evenly distributed without orientation. It is not suitable to use the inserted vibrator, otherwise the uniform distribution of the steel fiber will be destroyed. And when making prefabricated parts (blocks), also can use the plane shaking table construction.

(4) most of steel fibre reinforced castable used in constructing only contact with high temperature gas, or solid material of industrial kiln lining, such as electric furnace roof, the ladle cover, heating furnace, soaking pit furnace roof and wall, heat treatment furnace lining, high temperature cyclone separator lining, cooling tube cement rotary kiln lining, as well as the vertical roasting furnace lining and so on. It can also be used as containers, flow tanks and components in discontinuous contact with high temperature melt, such as steel discharge tank for electric furnace, integral spray gun for jet metallurgy, argon gun blowing, desulfurization agitator for molten iron. Because the temperature fluctuation, thermal stress and mechanical stress are large in the case of discontinuous (intermittent) use, the thermal shock resistance and mechanical vibration resistance can be improved by steel fiber reinforcement.