The Mineral Composition of Refractories

The mineral composition of refractories depends on its chemical composition and technological conditions. Due to the different technological conditions, the types, quantities, grain sizes and bonding conditions of the materials with the same chemical composition are different, and their properties may also be quite different. For example, for siliceous products with the same SiO2 content, because SiO2 may form two kinds of mineral scale quartz and square quartz with different structural properties under different technological conditions, some properties of the products will be different. Even if the mineral composition of the material is certain, the grain size, shape and distribution of the mineral phase will have a significant effect on the properties of the material.

The mineral composition of refractories can be determined by the change of heating phase of raw materials, the interaction of each material in the production process, the compounds or phase changes formed, so as to determine the production process of refractories, the quality of products and the conditions under which the materials are used.

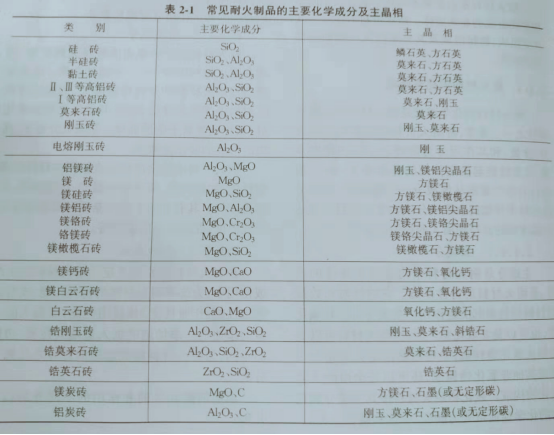

The mineral composition of refractories can be divided into two categories: primary phase and secondary phase. The main crystal phase refers to the crystal phase with high melting point and the main body of the material structure. The properties, quantity and bonding state of the main crystal phase directly determine the properties of the material. The main chemical composition and main crystal phase of common refractory products are shown below.

Matrix refers to the combination of large crystals or aggregates in refractories. The matrix plays an important role in the properties of the material. When used, the matrix is often destroyed first. Adjusting and changing the matrix of the material can improve the performance of the material.

Most refractory products can be divided into two categories according to their main crystal phase and subcrystal phase composition: one is multi-component refractory products containing crystal phase and glass phase, such as clay brick, silicon brick and so on; the other is multi-component products containing only crystal phase, the matrix is mostly fine crystal, such as magnesia brick, chromium-magnesium brick and other basic refractories. When these products are sintered at high temperature, a certain amount of liquid phase is produced, but the liquid phase does not form glass phase when cooling, but forms a crystalline matrix, which binds the main crystal phase together. The composition of the matrix crystal is different from that of the main crystal phase.