Refractory Plastic Material

Refractory clay with certain plasticity constructed by tamping method is called refractory plastic. Refractory plastics generally want to be made into the form of mud used, when the construction of the construction with the ramming hammer ramming will produce plastic deformation without fracture or collapse, the force removed can still maintain the shape after deformation. In American ASTM, it is stipulated that when measured with plasticity index tester, deformation index greater than 15% is plastic, and less than 15% is ramming material. In China's national standards stipulated: deformation index between 15% and 40% for plastic. Strictly speaking, refractory plastic should be a kind of semi-rigid wet plastic material. When the plasticity index is more than 40%, the shape-preserving property is not good, and it is easy to collapse due to ramming vibration. The plasticity index is less than 15%.

The composition of refractory plastics is similar to that of other unshaped refractories, which are composed of refractory aggregate and powder, binder and plasticizer. Different admixtures can be added according to the requirements of use, such as preservative, antishrinking agent, antifreeze, etc.

The varieties of refractory plastics are mainly classified according to the binder and main materials used, such as according to the binder classification of clay bonded plastics, phosphoric acid bonded plastic, aluminum sulfate bonded table plastic, tar-asphalt or resin combined plastic. The materials are siliceous, clayey, high-alumina, jadeite, zirconite, carbonaceous and/or siliceous carbide, magnesite, and magnesite, which means that refractory materials of various properties can be made into refractory plastics. However, the refractory plastics used in large quantities are mainly aluminum silicate (viscous and high aluminum) plastics.

Aluminum clinker processing made of a certain particle size composition of aggregate and powder, and admixture composition of the mixture, by adding water mixed into mud, and then by pressurization or extrusion into a certain plasticity of the brick-like material called clay combined plastic. The characteristics of clay - bonded plastics are good thermal shock resistance and spalling resistance.

As a combination of plastic binder clay, ball clay, wood node clay, kaolin. Generally speaking, it is required that the combined clay itself has good plasticity and sintering property. The colloidal particles in the clay should be more, hygroscopicity should be large, and humus should be appropriate, while the associated mineral non-colloidal substances should be less and alkali content should be low. Clay particles should be flat to increase the area of contact between them. Plasticizers can also be added to improve the plasticity of the bonding clay. Plasticizers should be surface active materials, which can be adsorbed on the surface of clay particles or superfine powder particles to form slippable bond between particles. The substances that can be used as plasticizer for clay are lignosulfonate, methyl cellulose, carboxymethyl cellulose, polyacrylate, polyvinyl alcohol, naphthalene sulfonate, etc. However, when plasticizers are used, their effect on plasticity must be verified by experiments, because some plasticizers can affect the storage life of plasticity and other physical properties.

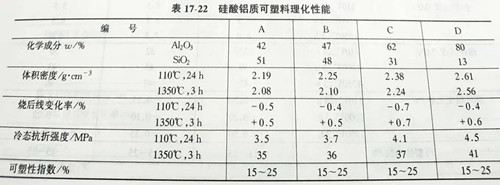

Clay combined plastic ingredients are generally: refractory aggregate 55%~65%, refractory powder 20%~ 30%, combined (soft) clay 10%~15%. The maximum allowable size of refractory aggregate is 8 mm, and the aggregate size is 8~5 mm, 35% ~ 40%. 5~ 3 mm, 30% ~ 35%; < 3 mm,25% ~ 30%. The size of refractory powder is less than 0.074mm accounting for more than 90%. Combined clay particle size should be less than 0.074 mm accounted for more than 95%. Antishrinking agent (such as bluestone or quartz) is usually added from refractory powder. Physical and chemical properties of four kinds of aluminum silicate plastics prepared with clay clinker and high aluminum clinker are shown in table 17-22.

Clay bonding plastic is mainly used as the lining body of the top and wall of the steel rolling heating furnace, and can also be used as the lining of various heat treatment furnaces. When making heating furnace inside the village, the general service life can reach 5 years above; As the lining of the preheating section of the heating furnace, the service life can reach more than 10 years.

Phosphoric acid can be combined with plastics

Phosphoric acid or acid aluminum phosphate as the binder, clay clinker, high aluminum clinker or corundum as the aggregate, plastic clay with plastic refractory clay and preservation agent is called phosphoric acid bonded plastic. Phosphoric acid bonded plastic is characterized by good bonding strength, wear resistance and thermal shock resistance.

With phosphoric acid or acid aluminum phosphate as binder, with phosphoric acid root with the plastic clay in the plastic substrate, or the active alumina powder material, or corundum powder AI2O3 reaction, generate insoluble orthophosphoric acid aluminum (AIPO4 xH2O) of sediment and cause premature plastic hardening, lose plastic plasticity to construction, so must add preservatives. The test shows that the preservative which can delay the premature hardening of phosphoric acid combined with plastic is oxalic acid, citric acid, tartaric acid, acetylacetone, 5-sulfonate salicylic acid, etc. The storage effect of oxalic acid is better, and the storage life can be extended from 6 months to about 1 year with the different amount (1%~4%).

The aggregate and powder size composition of this type of plastics is similar to that of clay bonded plastics. Its plasticizer material (agent) mainly with plastic clay, can also use organic plasticizer. Phosphoric acid bonded plastics are composed of: refractory aggregate greater than 100m3, 53%~65%, refractory powder less than 100m3, 35%~45%. Phosphoric acid solution with a density of 1.20~1.35g/cm3 is used for binders, and the addition amount is 9%~11%.

In the production of phosphoric acid binding plasticity blank, a two-step mixing process should be adopted. In the first step, 60% of the total demand of phosphoric acid solution should be mixed with refractory aggregate, powder and plastic clay. After mixing evenly, the material is trapped for 24h to make

Refractory aggregates can fully adsorb phosphoric acid solution and make the iron contained in the refractory aggregates (brought in by the breaking) can fully reverse the phosphate radical, H2 gas should be released. Then, the second step of mixing was carried out. During the mixing, preservatives and the remaining 40% phosphoric acid solution were added. When the mixing reached the required plasticity index, the blank was pressed or extruded, and the blank was sealed and stored with plastic film.

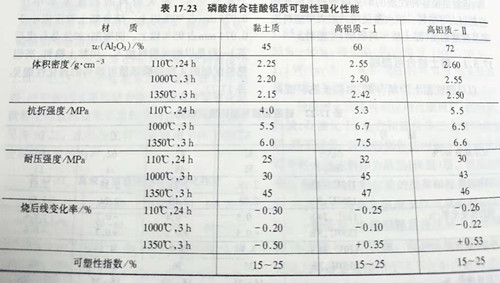

The general physical and chemical properties of phosphoric acid bonded plastics prepared from clay clinker and high aluminum clinker with a density of 1.25 g/cm3 phosphoric acid solution are shown in table 17-23. High temperature wear-resistant plastics can be prepared by using aluminum phosphate solution as binder, corundum as aggregate, and Al2O3 fine powder and micro powder as powder.

Aluminum phosphate or phosphoric acid can be combined with plastic in metallurgy, petrochemical, electric power and mechanical industry and other industrial kilns have a wide range of applications, mainly used for heat shock, erosion resistance, wear resistant liner, such as the heating furnace burner, cement rotary kiln outlet, shaft kiln feed mouth, high temperature cyclone separator lining.