What's the difference between refractory mortar and refractory cement?

Refractory mortar at any time is matched with refractory bricks used materials, such bonding and masonry methods, some customers will wonder why not use refractory cement? the refractoriness of refractory cement is much higher than refractory mortar, also the setting strength of refractory cement is not higher than refractory mortar? Let's take a look at these two products and to find the answer.

Refractory mortar is also known as fire mortar or joint material (powder). Used as joint material for masonry of refractory products. It is composed of refractory powder and admixture. Almost all refractory materials can be made into powder for the preparation of refractory mortar. The common refractory mortar made of refractory clinker powder and proper amount of binder has low strength at normal temperature, and it has high strength only when ceramic bond is formed at high temperature. Chemical bonded refractory mortar with gas rigid or thermal-hard binding materials as binder produces a certain chemical reaction before the formation of ceramic bonding temperature and hardening. The particle size of refractory mortar is different according to the use requirements, and its limit particle size is generally less than 1mm, and some are less than 0.5mm or finer. The selection of refractory mortar material should be considered in accordance with the material of masonry refractory products. In addition to being used as joint material, refractory mortar can also be used as protective coating of lining body by smearing or spraying method. 1, good plasticity, convenient construction; 2, high bond strength, strong corrosion resistance;

There are many kinds of refractory mortar, which are usually divided into ordinary refractory mortar (580~1250℃), intermediate refractory mortar (1300℃~1770℃), senior refractory (1770~2000℃) and super refractory (over 2000℃) according to the refractoriness. According to chemical characteristics, it is divided into acid refractories, neutral refractories and alkaline refractories. In addition, there are refractory mortar for special occasions.

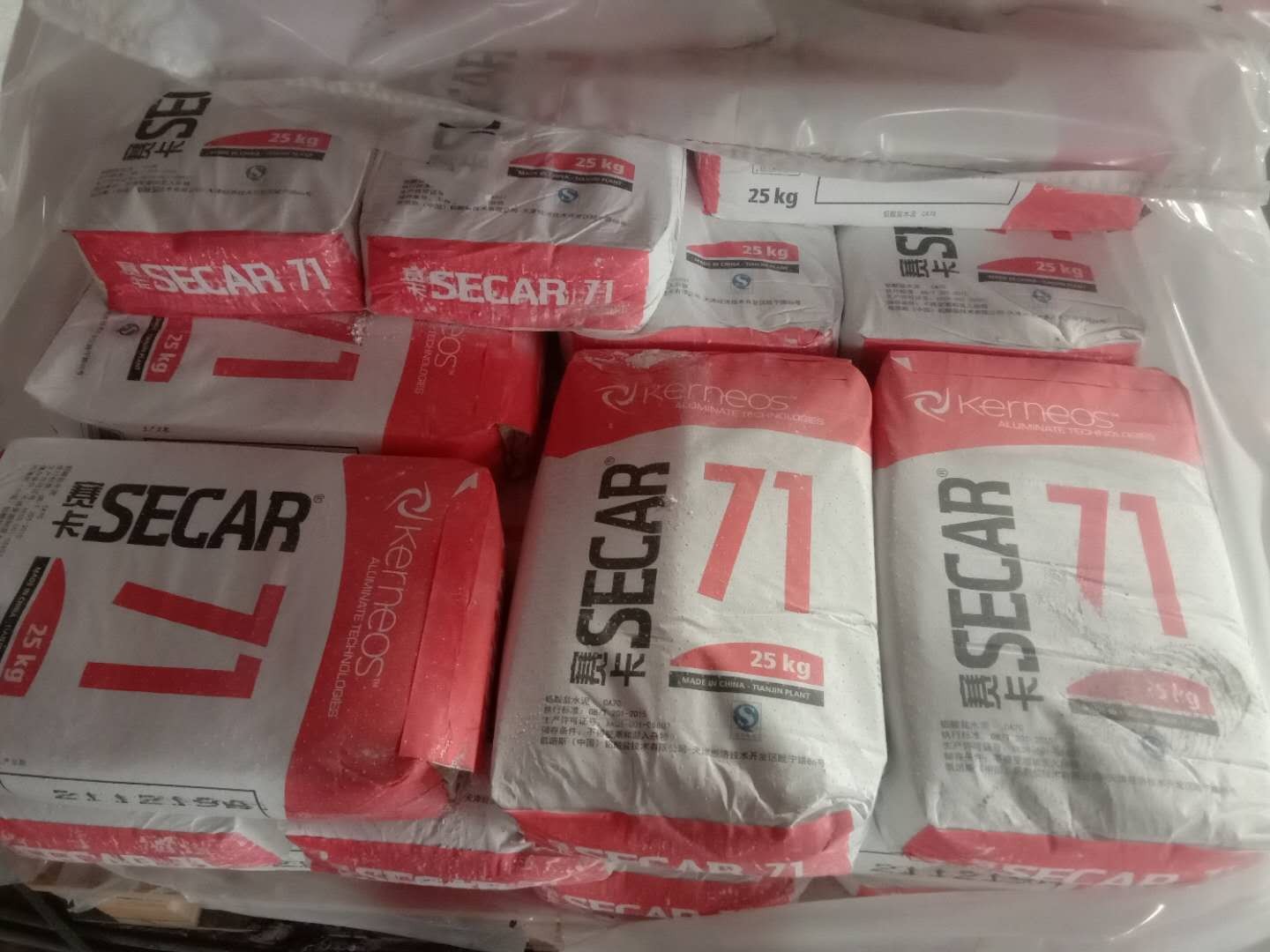

Refractory cement is also called aluminate cement. Aluminate cement is a hydraulic cementing material made from bauxite and limestone by calcining calcium aluminate as the main component and alumina content of about 50%. Aluminate cement is usually yellow or brown, but also gray. The main minerals of aluminate cement are calcium aluminate (CaO·Al2O3, short for Ca) and other aluminates, as well as a small amount of dicalcium silicate (2CaO·SiO2), etc. It is used for cementing all kinds of refractory aggregate (such as corundum, calcined high alumina, etc.) to make refractory castable or refractory concrete, which is used for lining of industrial kiln.

The biggest difference between the two materials is that one is directly used as a finished product, while refractory cement is used as a raw material to cement all kinds of refractory aggregate into refractory castable for kiln lining. So the use properties of the two materials are not the same, which forms the effect in different use methods.

TAG: refractory cement refractory mortar