Semi-Silica Brick

The al2o3 content of semi-silicon brick is 15% to 30%, and the sio2 content is more than 65%. it is a semi-acid refractory product. The raw materials for producing semi-silicon brick are mainly natural high silicon clay and wax stone, and also mixed raw materials with clay and silica.

The use properties of semi-siliceous refractory products are between siliceous products and clay products. Its thermal shock resistance is better than that of siliceous products, and the volume change is small and some of them are slightly expanded in the process of use, which is beneficial to the air tightness of masonry. In addition, when this kind of product is in contact with molten slag at high temperature, the surface of the product can form thick 1~2mm with high viscosity and high silica glaze, which is beneficial to the corrosion resistance of masonry to acid slag and metal melt, thus improving the corrosion resistance of the product, and the initial temperature of load deformation is high, so in some cases, its service life is no less than that of general clay brick.

Semi-silicon brick is mainly used in coke oven, acidized iron furnace, metallurgical furnace flue and steel barrel lining.

The characteristics of the production of semi-silicon brick

The production process of semi-silicon brick can be divided into firing or not. Most of the unfired bricks are made of sodium silicate as binder. The production process of fired brick is roughly the same as that of clay brick, but it also has its own characteristics, mainly as follows:

Whether clinker is added or not is determined by the characteristics of the raw material and the requirements for the use of the product. Silica clay firing shrinkage, can be used without clinker. In order to improve the thermal shock resistance of semi-silicon brick, 10% ≤ 20% clinker should be added.

If there are less melts and coarse quartz particles in the raw materials, the density and strength of the semi-silicon brick are low and the strength is poor, but the thermal shock resistance is good and the load softening temperature is high; on the contrary, the fire resistance of the product is poor. Therefore, when adding quartz sand or silica clinker, whether to add particle material or fine particle material should be decided according to the use condition of the product.

When the semi-silicon brick is below 1250 ℃, the volume shrinkage is not obvious, and the volume shrinkage is larger with the increase of liquid phase at high temperature, so the firing temperature of semi-silicon brick should be higher than that of clay brick, generally in the range of 1350 ℃ ~ 1410 ℃, in order to obtain high density products.

When the wax stone is used as the raw material of the semi-silicon brick, the process shall be determined according to the chemical composition of the wax stone raw material. The main component of the wax stone is small in weight loss after the dehydration of the pyrophyllite, and the lattice structure thereof is still maintained, so that the green brick can be directly made from the raw material, and the mineral resources can be fully utilized to reduce the production cost. In order to prevent the burning and expansion, the strength is reduced, and the wax stone raw material can be burnt into a mature material, and a small part is added when the material is prepared. It should also be noted that the hydroscopicity of the wax stone is very poor, so the water content of the mud material should be strictly controlled, otherwise cracks will be generated when the wax is formed.

Technical index of semi-silicon brick

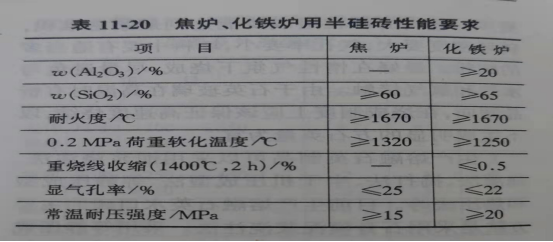

The semi-silicon brick has good resistance to acid slag, and has high high-temperature structural strength and stable volume. It is mainly used for building a coke oven, an acidic iron furnace, a metallurgical furnace flue, a steel ladle lining, and the like. Table 11-20 lists the performance requirements of the semi-silicon brick for coke oven and cupola.