Carbon block、Carbon Paste Products

The carbon block of electric furnace has good corrosion resistance and heat resistance, and is used to build calcium carbide furnace, ferroalloy furnace, graphitization furnace and other high temperature working lining. Large calcium carbide furnaces adopt a complete set of customized carbon blocks, which, like blast furnace carbon blocks, need to be processed accurately and sent to customers after pre-installation in the manufacturing plant. The raw materials and production process used in the production of electric furnace carbon block are exactly the same as those used in the production of blast furnace carbon block, but the mechanical processing of most electric furnace carbon blocks is relatively simple, only the two ends need to be cut flat, and the surface does not need to be machined.

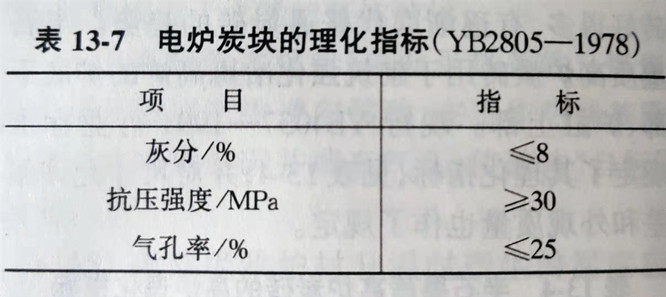

The code of the electric furnace carbon block is TKD, the technical conditions, the size and the allowable deviation and the shape, the metallurgical industry standard YB2805-1978, and the physical and chemical indexes of the electric furnace carbon block are shown in Table 13-7.

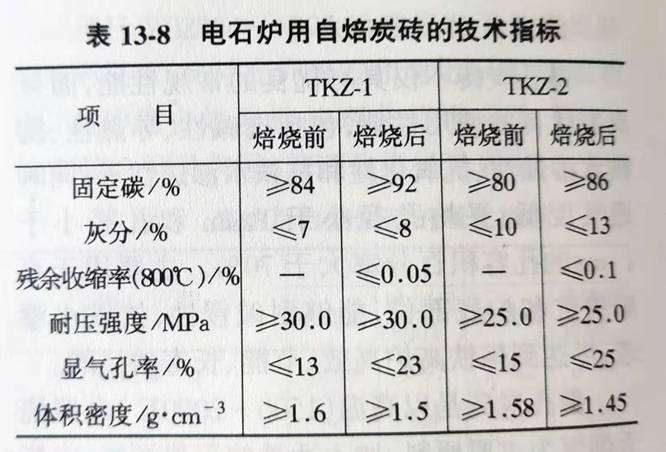

The self-baked carbon brick for calcium carbide furnace is made of anthracite treated at high temperature and made by molded high frequency vibration molding process, which is used for masonry large and medium calcium carbide furnace bottom and molten pool lining. According to the capacity of calcium carbide furnace transformer, self-baked carbon brick can be divided into two categories: the first type is suitable for calcium carbide furnace greater than or equal to 1000kV ·A. Code name KTZ-1. The second kind is suitable for calcium carbide furnace less than 1000kV. Code name TKZ-2. The current national standard GB6153-1985 specifies its classification, shape and size, technical index, allowable deviation of size and surface quality. Table 13- 8 is the self-baked carbon brick for calcium carbide furnace. Technical indicators.

Cathode carbon block for aluminum electrolysis is made of calcined anthracite, metallurgical coke, graphite as aggregate and coal tar pitch as adhesive. It is mainly used to make carbon lining of aluminum reduction cell as electrolyte and produced aluminum liquid for aluminum electrolysis reaction, and to export current through steel rod inserted into cathode. Aluminum electrolytic production requires cathode carbon block to resist high temperature, scour, molten salt and molten aluminum erosion, high conductivity, certain purity and sufficient mechanical strength to ensure that the electrolytic cell has a long service life and is conducive to reducing the power consumption of aluminum production, and the quality of aluminum products is not polluted.

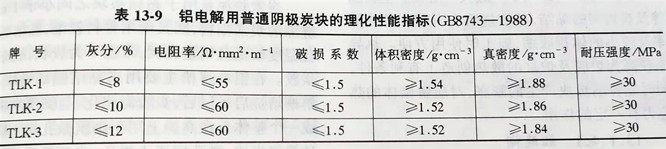

Cathode carbon block for aluminum electrolysis can be divided into bottom carbon block and side carbon block. The bottom carbon block used to build the bottom of the cell is not only the lining material of the electrolytic cell, but also the cathode when the cell is electrified. Therefore, the specific resistance of the bottom carbon block should be lower in addition to the high temperature and corrosion resistance of the bottom carbon block. The side carbon block is used to build the side part of the aluminum reduction cell, which forms the main lining body of the side part of the cell. The side carbon block is not used as a conductor, but as the corrosion resistant lining material of the cell. The physical and chemical properties of common cathode carbon blocks for aluminum electrolysis are shown in Table 13-9.

The common cathode carbon block is made of ordinary calcined anthracite (calcination temperature 1250 ≤ 1350 ℃) as the main aggregate, metallurgical coke as powder, medium temperature coal tar pitch as binder, extrusion or vibration molding, calcination at 1100 ℃ (product temperature).

The grades of ordinary cathode carbon blocks for aluminum electrolysis are TLK-1, TLK-2 and TLK-3, and the technical requirements are stipulated in the current national standard GB8743-1988. The physical and chemical indexes of ordinary cathode carbon blocks for aluminum electrolysis are shown in Table 13-9. The cross-sectional area of ordinary cathode carbon blocks in China is 400 mm ×400 mm, and the length of common cathode carbon blocks varies from 550 to 2000 mm. The cathode carbon block is slotted below (commonly known as the swallowtail groove) for inlaying the cathode steel rod. There are strict requirements for size deviation and appearance.

There are two kinds of semi-graphite carbon block according to the different production process: one is high quality high temperature electric calcination of anthracite (calcination temperature 1800 ≤ 2000 ℃), or more graphite fragments or even all of them are used as aggregates. The molded green products are only calcined (calcination temperature does not exceed 1200 ℃) and do not need graphitization heat treatment. This carbon block is called semi-graphite carbon block; The other uses more easily graphitized coke as aggregate and then enters the graphitization furnace for heat treatment at 1800 ℃. The carbon block is called semi-graphite carbon block, the former has higher strength and hardness, and then enters the graphitization furnace for heat treatment at 1800 ℃. The former has higher strength and hardness, and then enters the graphitization furnace for heat treatment at 1800 ℃. The electrical conductivity and integrity of the patients are better. Semi-graphite cathode carbon block is produced with high temperature coal tar pitch and modified coal tar pitch with a certain proportion of coal tar or anthracene oil as adhesive.

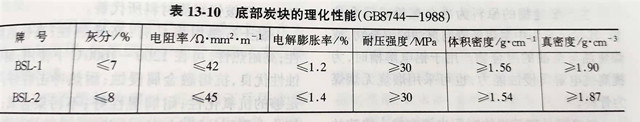

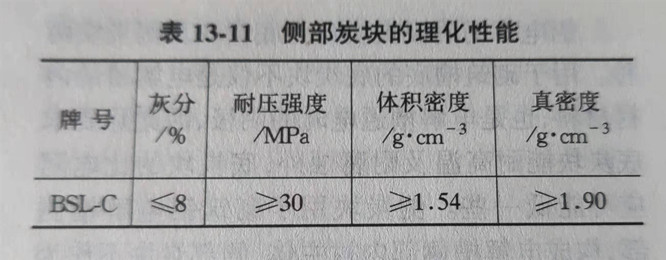

Semi-graphite cathode carbon block has good properties such as good conductivity and strong corrosion resistance. It can reduce power consumption and increase cell life in aluminum reduction cell. It is an excellent lining material for electrolytic cell. Its classification and technical conditions are stipulated by the current national standard GB8744-1988. The grade of semi-graphite bottom carbon block for aluminum electrolysis is divided into BSL-1,BSL-2; side carbon block and BSL-C,. The physical and chemical properties of the carbon block are shown in Table 13- 10 and Table 13-11. The size of semi-graphite cathode carbon block is 515mm × 450mm × 3250mm.

The carbon paste product is used for the bonding between the bottom leveling layer and the expansion joint of the furnace wall and the carbon block, and has good thermal conductivity and small volume shrinkage after the roasting, and is convenient to use in construction. The heat conductivity is higher than that of the bottom of the furnace and the hearth of the furnace, favorable conditions are created, and the expansion of the carbon blocks can be accommodated, so that the thermal stress of the masonry can play a certain role.

1) the coarse paste is made by mixing high-temperature electric-fired anthracite, artificial graphite, silicon carbide as main raw material, coal pitch, coal tar and mixed oil of oil-oil blending additive as bonding agent, and mixing. The coarse paste is a carbon paste which is used as a bottom carbon ramming layer, is filled with a wide gap between the carbon block and the carbon block and between the carbon block and the masonry, and can be used for building an aluminum electrolytic cell, a blast furnace and a mine thermal electric furnace.

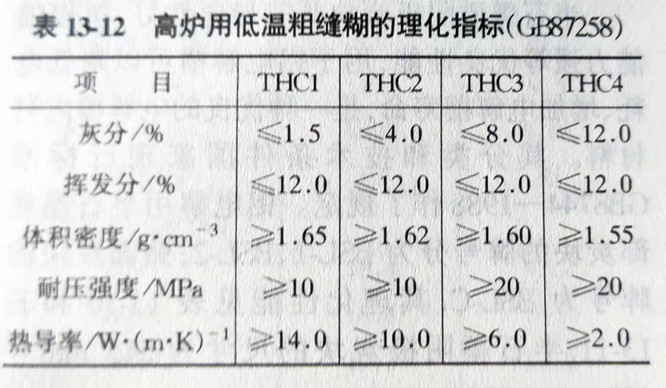

The low-temperature coarse-seam paste for blast furnace is divided into four grades of THC1, THC2, THC3 and THC4 according to the physical and chemical indexes. The current national standard specifies the physical and chemical indexes, see Table 13-12.

2) Fine seam paste

The raw material for producing the fine-seam paste is a metallurgical coke powder or a mixed coke powder, and the binder is a mixture of medium-temperature coal pitch and diesel oil, or a mixture of coal tar and diesel oil. In that case of an aluminum electrolytic cell, it is also possible to use the coal-fired anthracite as an aggregate in order to improve the resistance to corrosion of the electrolyte.

Fine seam paste is a carbon paste used to fill smaller gaps when building carbon blocks. When building aluminum reduction cell, blast furnace and mine furnace, the thin seam paste is used to fill the gap less than 2mm. It is used to bond the gap between the carbon blocks on the side of the aluminum reduction cell. After the roasting of the cell is started, the fine seam paste is gradually coking and coke with the carbon block as a whole, forming a container containing aluminum liquid and electrolytes. The quality standard of fine seam paste (YB2807-1978) in China is as follows: volatile matter is not more than 45%, extrusion seam test is not more than 1 mm.

3) carbon mortar

Carbon paste is used to bond carbon paste which is smaller than 1mm gap between carbon blocks. Carbon paste is also called carbon adhesive because of its fine aggregate, low softener temperature and large dosage. The aluminum reduction cell is mainly used to bond the side carbon block. After the roasting of the cell is started, the carbon slime coking and the side carbon block form a whole. It is used in blast furnace to build microporous carbon-silicon carbide roasted carbon block, microporous molded small carbon block, semi-graphite calcined carbon block and microporous carbon block.

Carbon slime is based on high temperature electrically calcined anthracite, graphite, silicon carbide fine powder as the main raw materials, resin or coal pitch and coal tar mixture as the bonding material. The basic ratio of carbon mortar is 50% of powder less than 0.15mm and 50% of low softened temperature adhesive. The quality indexes of carbon mortar are as follows: ash content is less than 5%, volatile content is not more than 50%, fixed carbon is not less than 45%.