Clay-graphite Product

Clay fire-resistant products are fire-resistant products fired from fire-resistant clay and graphite as main raw materials. Is characterized in that the resistance to molten metal is good, the thermal shock resistance is high, and the oxidation resistance is better than that of the pure graphite product. The clay product is mainly used as a crucible for steel-making and smelting of non-ferrous metal, a distillation pot, a plug-head brick for ingot casting and a water-gap brick, and can also be used as a ladle lining brick. Due to the development of the iron and steel industry, especially the development of continuous casting technology, the clay graphite plug and the water gap have been replaced by the aluminum-carbon material.

Clay graphite crucible has the characteristics of high thermal conductivity; high thermal shock resistance; high heat resistance; can be used at 1200 ℃; good corrosion resistance, corrosion resistance of molten metal; good heat impact resistance; enough oxidation resistance; good wettability resistance; no pollution metal; good corrosion resistance of flux for molten metal; moderate price and so on, which is widely used in metal smelting.

The clay graphite crucible is made by using clay clinker, combined with clay and graphite as raw materials, and is molded by a plastic method, and is embedded in the coke powder and sintered at about 1400 DEG C. The graphite content is 30 to 50%, and the fire resistance is equivalent to that of the clay brick, and the thermal shock resistance and the chemical erosion resistance (such as the erosion of the anti-MnO and the FeO) are obviously improved. And is formed by the conventional plastic method. The production process of the graphite clay crucible is similar to that of the clay brick. But the blank needs to be carefully mixed, for a long time, to compare the moderate drying system and the different firing temperature.

The graphite clay crucible product requires a certain mechanical strength, can load the metal quality of the smelting, and is convenient for casting and casting operation. Good thermal conductivity, thermal shock resistance and slag resistance. By using asphalt and tar instead of the combined clay and silicon carbide instead of the clinker, the carbon-bonded graphite crucible is prepared, and a large number of applications are also gradually obtained abroad.

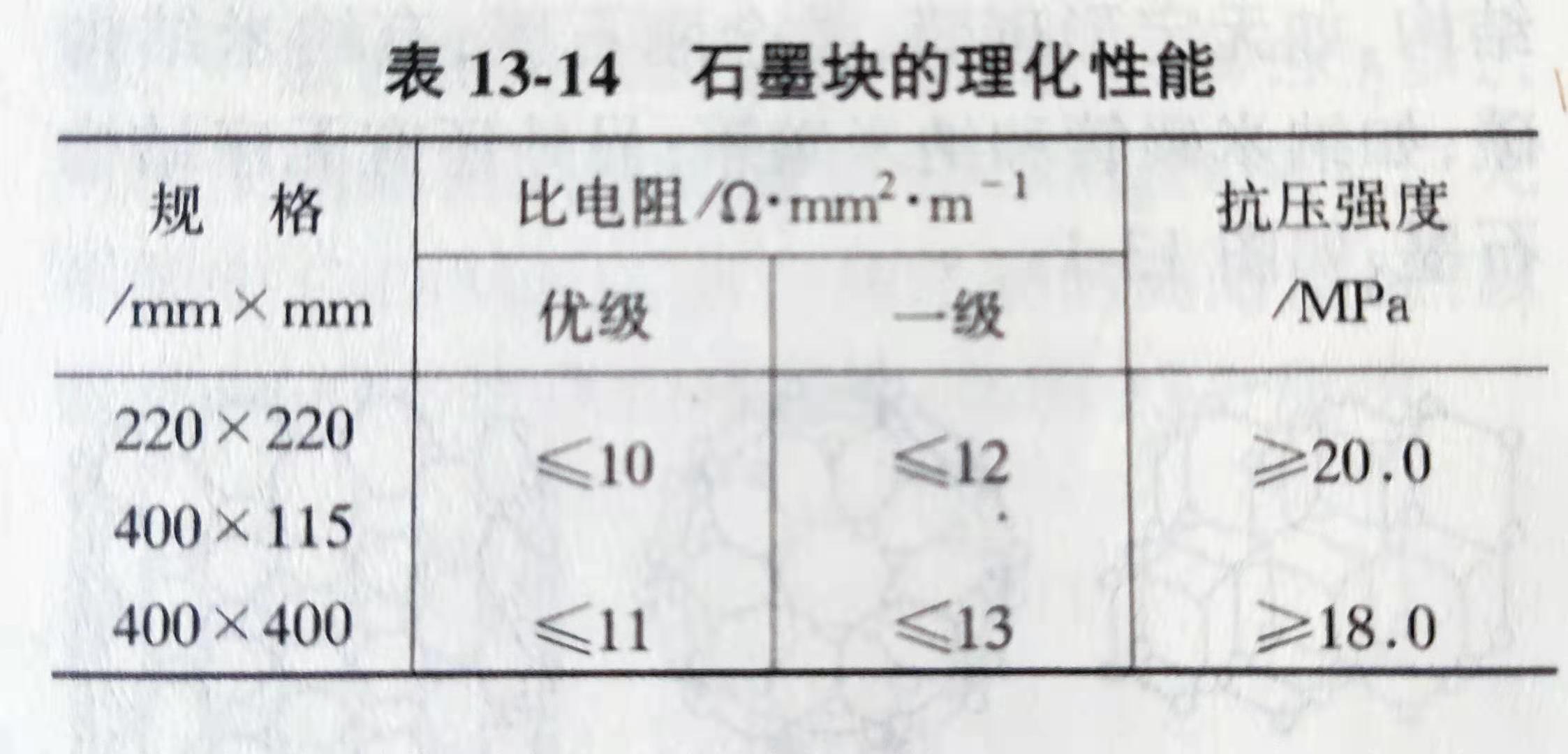

The crucible made from natural flake graphite and silicon carbide is made by combining high quality clay with natural flake graphite and silicon carbide as main raw materials. The quality index is shown in Table 13-13.

Graphite Block

Graphite block is a low ash and graphite material made of petroleum coke, asphalt coke as aggregate and powder, coal tar pitch as binder, molding, roasting, graphitization and machining. It is mainly used in three areas:

Its excellent conductive properties are used as conductive materials, such as the anode of magnesium electrolyzer and the conductive electrode of graphitization furnace.

Its excellent thermal conductivity and corrosion resistance are used as refractories, such as bottom masonry of ironmaking blast furnace or inner wall of graphitization furnace.

Graphite chemical equipment, such as block graphite heat exchanger, is made by dipping with synthetic resin or other resin after machining.

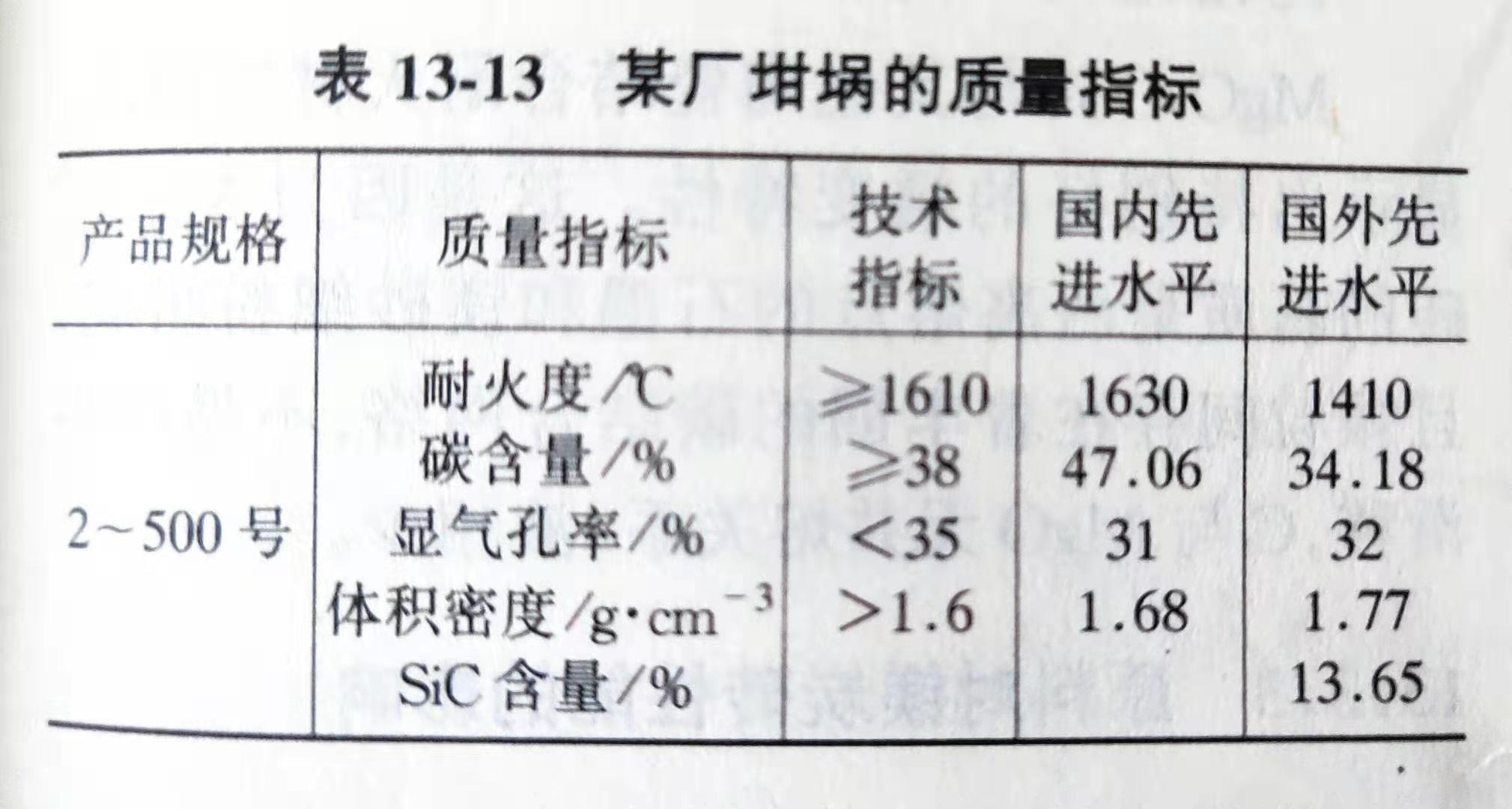

The technological process of producing graphite block is the same as that of graphite electrode production, but the process parameters are different. For example, the graphite block used in blast furnace bottom masonry is required to be dipped once in order to increase its volume density. Graphite blocks used to process graphite chemical equipment sometimes require fine particle structure, so the particle formulation is different. Graphite blocks used as conductive materials or refractories generally only determine the electrical resistance and compressive strength, the technical conditions of graphite blocks, the metallurgical industry standard YB2818-1978 (Table 13-14), and its size and allowable deviation as well as appearance quality are also specified. The cross section of graphite blocks is 1.