Carbon Material - Flake Graphite

Flake graphite is the main carbon material used to prepare mgo-c brick.

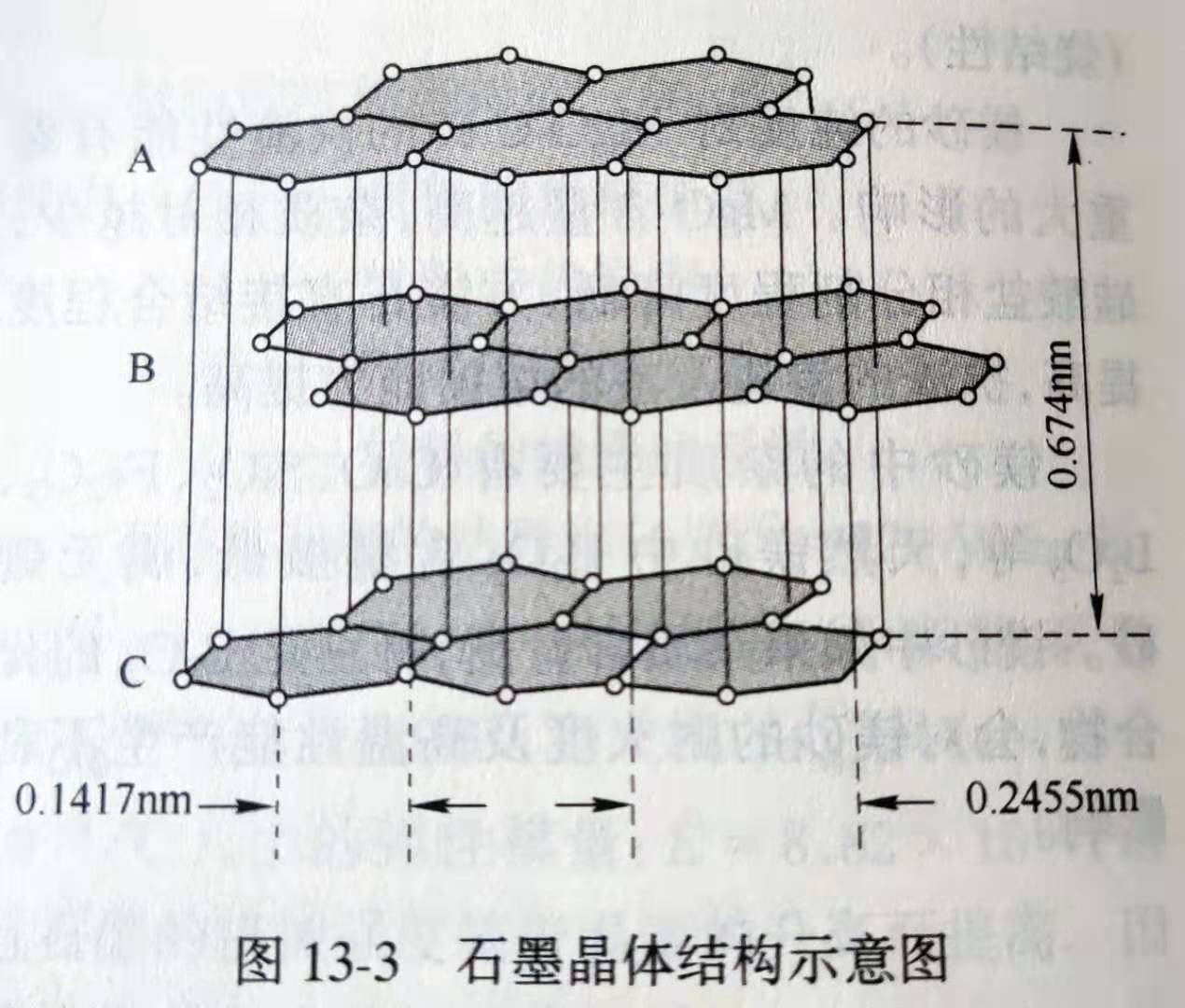

Flake graphite: natural crystalline graphite, shaped like fish scales, is a hexagonal crystal system, layered structure, metal luster, density of 2.1~2.3g/cm3, mohls hardness of 1~2, with good high temperature resistance, conduction, heat conduction, lubrication, plastic and acid and alkali resistance and other properties. The crystal structure is shown in table 13-3.

Technological characteristics of graphite

Graphite has the following characteristics:

(1) high temperature resistance. The melting point of graphite is 3850℃±50℃ and the boiling point is 4250℃. Even if it is burned by ultra-high arc, the mass loss is very small and the linear expansion coefficient is very small. The strength of graphite increases with the increase of temperature. At 2000℃, the strength of graphite is doubled.

(2) conduction of electricity and heat. The conductivity of graphite is twice as high as that of ordinary nonmetallic minerals. Thermal conductivity of steel, iron, lead and other metal materials. The thermal conductivity decreases with the increase of temperature.

(3) lubricity. The lubrication property of graphite depends on the size of graphite flake. The larger the flake, the smaller the friction coefficient, and the better the lubrication property.

(4) chemical stability. Graphite has good chemical stability at room temperature, can withstand acid, alkali and organic solvent corrosion.

(5) plasticity. Graphite is very tough and can be rolled into very thin sheets.

(6) thermal shock resistance. Graphite in the use of high temperature can withstand the temperature of the drastic change without destruction, temperature mutation, graphite volume change is not big, will not produce cracks.

Graphite classification and product brand

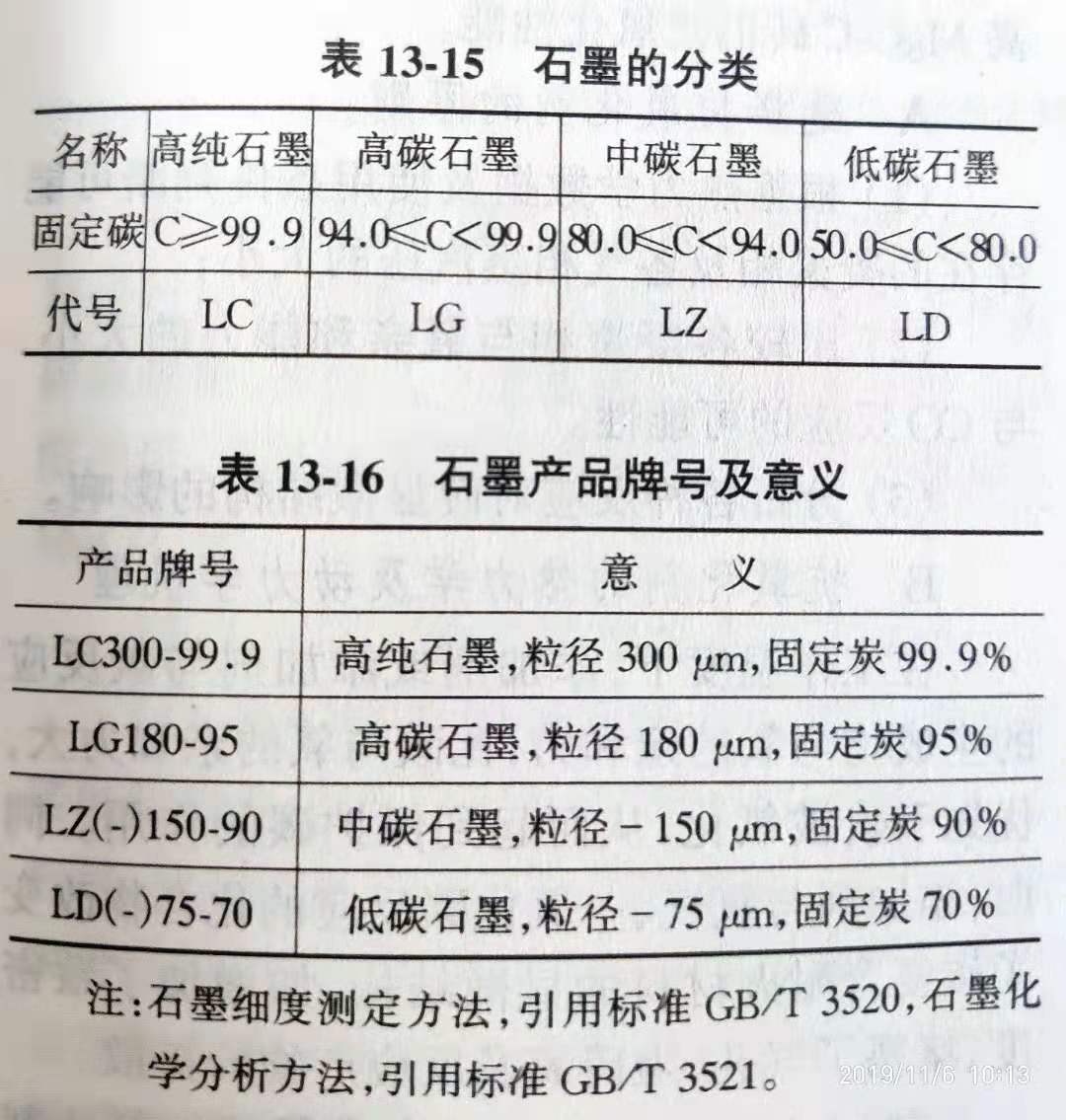

Flake graphite can be divided into four types according to the fixed carbon content. · high purity graphite, high carbon graphite, medium carbon graphite and low carbon graphite are shown in table 13-15. For other technical indicators, please refer to GB/T 3518-1995. In addition, according to the different particle size of graphite, graphite products are divided into a variety of different brands. The brand and significance of graphite products are shown in table 13-16.

As one of the raw materials for mgo-c brick production, the main properties of graphite, such as Fix carbon content, particle size, Ash, shape, volatile content and moisture, also affect the performance and use effect of mgo-c brick.

Fixed carbon: it refers to the components of graphite other than volatiles and ash. Volatiles are organic and inorganic substances composed of low-melting materials.

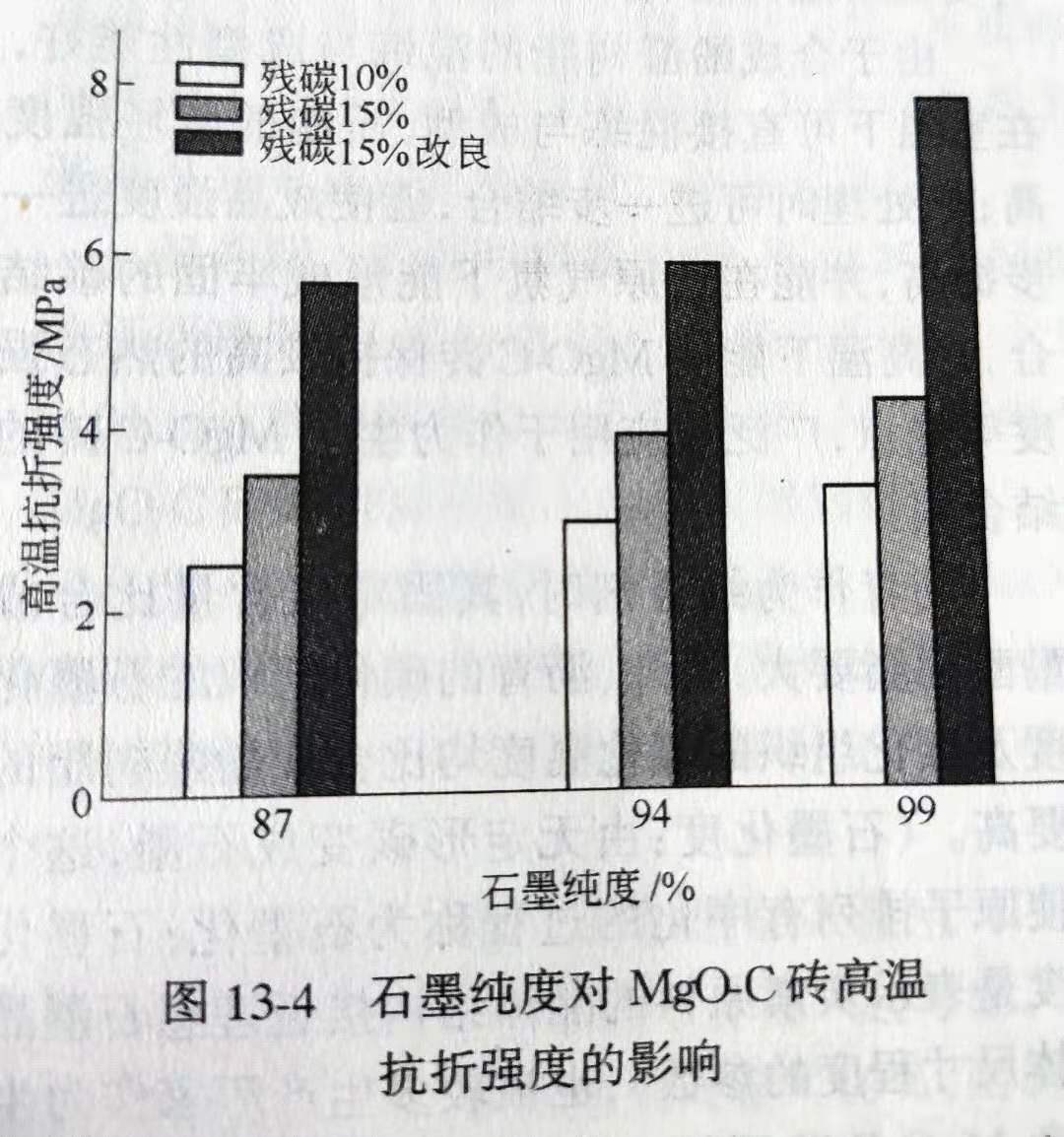

The higher the fixed carbon content of graphite, the lower the ash content and volatile content, the better the structure of mgo-c brick produced in the process of using at high temperature, which is reflected in the high temperature flexural strength of the products.

Mgo-c brick produced with different purity of graphite as carbon material has obvious difference in structure. Mgo-c brick produced with low pure graphite, after high temperature treatment, due to the melting of graphite associated minerals into glass phase and reaction with magnesite or carbon, internal structural defects occur, so that the tissue structure of the product is weakened locally, and the high-temperature strength of the product is reduced. Table 13-4 shows the relationship between graphite purity and high-temperature bending strength of mgo-c brick.

At the same time, the purer the graphite, the better the erosion resistance of mgo-c brick. The volatiles in graphite will produce more volatiles in mgo-c brick during the heat treatment process, which makes the porosity of the products become larger, so it is adverse to the service performance of the products.

The particle size of graphite affects the thermal shock resistance and oxidation resistance of products. For flake graphite, the larger the flake, the better the flake resistance and oxidation resistance. This is because of the large scale quartz has a high thermal conductivity and a small specific surface area. As the flake graphite used in mgo-c brick production, its particle size is generally required to be 0.125mm. The thickness of flake graphite also affects the properties of the product. It is generally required that the thickness shall be no more than 0.02mm, preferably no more than 0.01mm. The smaller the thickness of flake graphite, the smaller the effective area of oxidation on the surface of the end, so the product has better oxidation resistance. This is because the edges of flake graphite oxidize 4 to 100 times faster than the surface.

Ash is the residue of graphite after oxidation. In general, the main components of flake graphite in ash are SiO2, Al2O3 and Fe2O3, accounting for 82.9%~88.6% of ash, and SiO2 accounts for 33%~59% of ash. The higher the ash content in graphite, the lower the slag resistance of mgo-c products.