Low carbon magnesium carbon brick

Low carbon magnesia carbon brick generally refers to a kind of low carbon composite material with the total carbon content less than 8%, with magnesia and graphite as the main raw materials, a certain amount of metal additives and organic binder.

Traditional magnesia carbon brick (refers to the carbon content in 10%~20%) has good thermal shock resistance and excellent slag resistance, which is due to its relatively high thermal conductivity (generally greater than 20W/m·K), non-wetting of graphite and slag, as well as the reduction of iron oxide in slag to make the slag viscosity larger. However, the direct heat loss caused by high graphite content is also high, and the high graphite content is unfavorable to the smelting of low carbon steel and super pure steel. Therefore, how to develop low carbon magnesia-carbon bricks with good thermal shock resistance and slag resistance as well as low thermal conductivity, which is conducive to the development of ultra-pure steel and secondary refining technology, has become the current development trend of magnesia-carbon bricks. With the decrease of carbon content in magnesium-carbon bricks, especially when the carbon content is less than 10%, the spalling resistance of magnesium-carbon bricks decreases obviously. This is the inevitable result of the fact that carbon cannot form a continuous phase or the degree of continuous phase decreases.

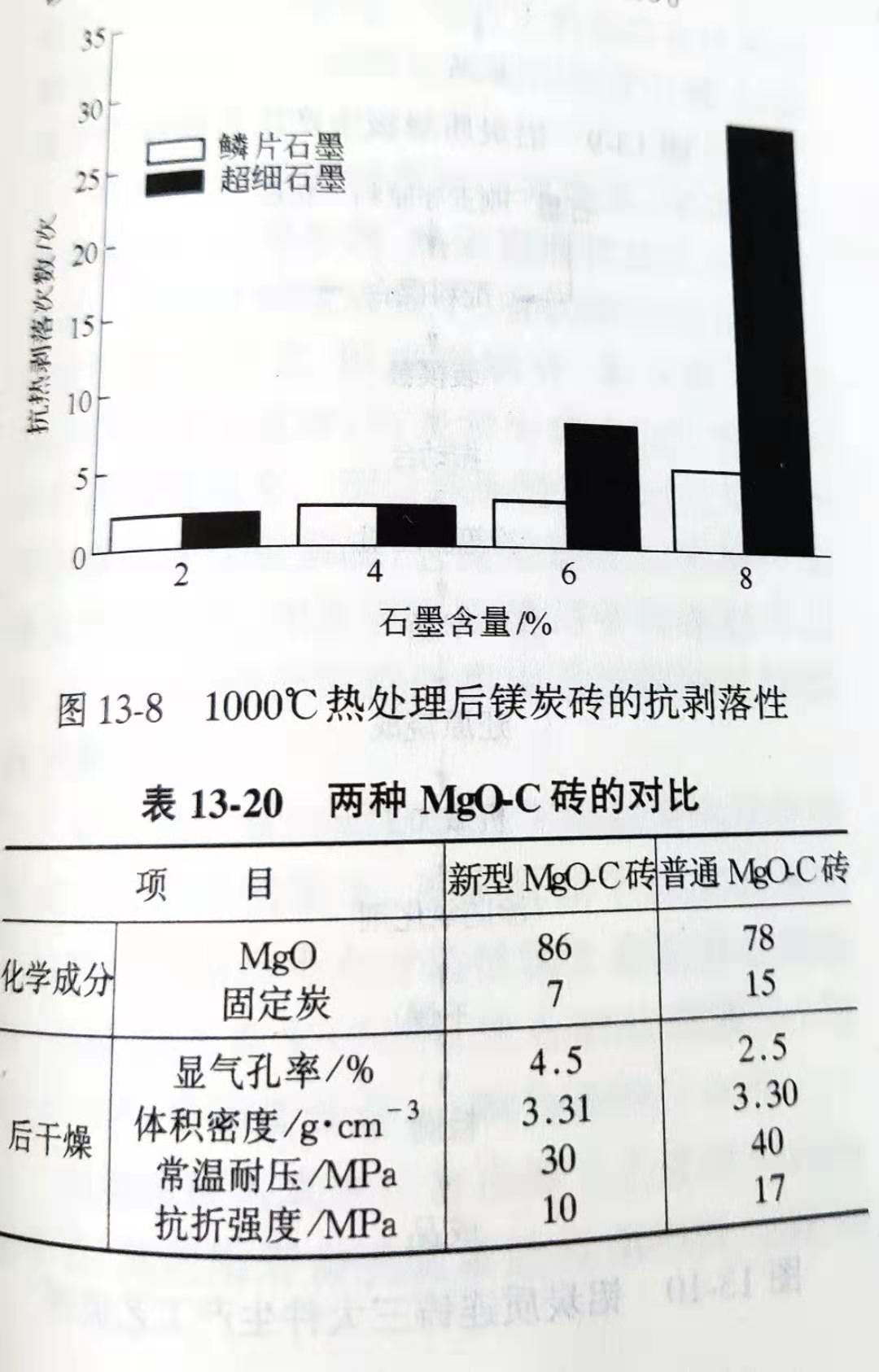

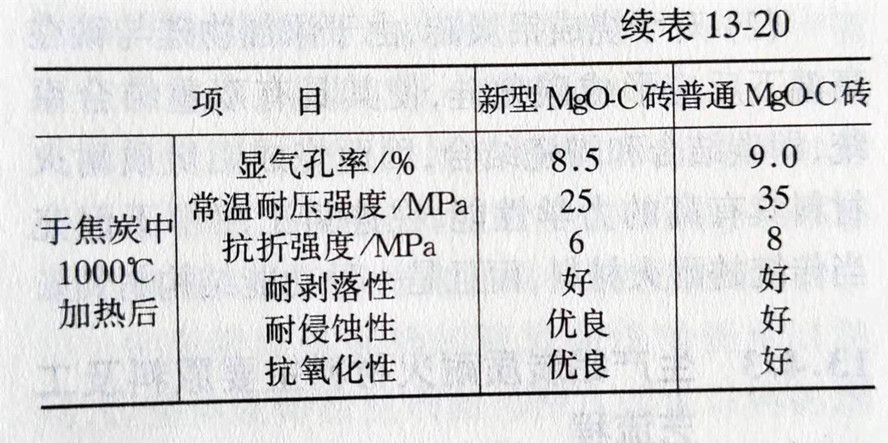

In order to improve the anti-spalling property of low carbon magnesium carbon brick, ultrafine graphite can be used instead of flake graphite. When the total carbon content exceeds 6%, the advantages of ultra-fine graphite can be demonstrated in the spalling resistance of magnesium-carbon bricks. As shown in figure 13-8, the addition of ultra-fine graphite can inhibit the over-burning of bricks, reduce the elastic modulus of bricks, and thus improve the anti-spalling performance of low-carbon mgo-c bricks. In addition, the surface treatment of magnesia can make the brick form more continuous distribution of tiny pores in the process of heat treatment, so as to reduce the thermal conductivity of magnesia carbon brick and improve the thermal shock resistance. As the carbonized structure of traditional phenolic resin is glassy, the anti-spaking property of the material is poor, while the organic binder without phenolic resin can improve this problem, the corresponding results are shown in table 13-20.

Aluminum carbonaceous refractory refers to the carbon composite refractory which is made of alumina and carbon as raw materials and, in most cases, other raw materials, such as SIC and Si, are also added, and bonded with asphalt or resin and other organic binder. Broadly speaking, alumina and carbon as the main components of the refractory are called aluminum carbonaceous refractory. Aluminum carbonaceous refractories can be divided into two types according to their production process: non-aluminum carbonaceous refractories and aluminum carbonaceous refractories.

Non-aluminized carbonaceous refractories belong to carbon-bonded refractories, which are widely used in blast furnace, ladle and other hot metal pretreatment equipment due to their superior oxidation resistance and Na2O slag erosion resistance. Calcining aluminum carbonaceous refractory belongs to the ceramic combination type refractories, due to its high strength, good erosion resistance and thermal shock performance, thus a lot of use of use of slide gate system in continuous casting skateboards brick (Sliding gate bricks) and continuous casting 3 big, namely the long nozzle, Ladle shroud), submerged nozzle (Sub - entry nozzle) and overall stopper (Monoblock stopper), etc.

Alumina has high resistance to acid, alkaline slag, metal and glass solutions. It is used in oxidizing atmosphere or reducing atmosphere under high temperature, and it can get good effect. Carbon raw materials, especially graphite, have high thermal conductivity and low linear expansion coefficient. Therefore, aluminum carbon conversion has the following properties:

(1) aluminum carbonaceous refractory has excellent slag resistance and thermal shock resistance. Compared with magnesium carbonaceous refractories, aluminum carbonaceous refractories have higher resistance to alkali (Na2O) erosion and TiO2 slag erosion.

(2) for calcining aluminum carbon brick, because of the added content of silicon and silicon carbide, carbon reaction at high temperature has the dual system, namely, carbon and ceramic, thus burning aluminum carbonaceous refractory with high mechanical properties, in the continuous casting process not only ACTS as the traditional refractory material, and is a kind of functional structure material.