Aluminum-Magnesia Carbonaceous Refractory

Aluminum-magnesia carbonaceous refractory is a kind of composite refractory made of alumina, magnesium-alumina (or magnesium-alumina spinel) and carbon as the main raw materials. In most cases, it also adds other raw materials (such as metal Al powder) and is bonded with asphalt or resin and other organic binder. Broadly speaking, alumina, magnesium oxide and carbon as the main components of the refractory are called aluminum-magnesium carbon refractory. Aluminum-magnesium carbon refractories can be divided into two categories according to their principal components: one is alumina based products, commonly expressed by AMC; the other is magnesium oxide based products, commonly expressed by MAC.

With the development of continuous casting and the technology of refining outside the furnace, molten steel temperature in ladle, and residence time prolonged, the original clay bricks, high aluminum bricks or tar dolomite brick lining has far cannot meet the requirements, lu mei temple air brick is developed in the late 1980 s under this background, it is mainly used for ladle lining, the service life than the original clay bricks, high aluminum bricks or tar 2 ~ 5 times higher than that of dolomite brick is the mainstream of the ladle lining in the early 1990 s.

Alumina magnesia carbon refractories is in high performance magnesium carbon and aluminum carbonaceous refractory developed on the basis of, is the high alumina brick and dolomite brick of ladle lining of alternatives, but compared with that by alkali and acid and alkali of two sexes refractory oxide aluminum magnesium carbon brick not only has excellent chemical and thermal stability, and excellent thermal and mechanical properties.

(1) high resistance to steel penetration. Because of the expansion of spinel reaction between alumina and magnesia in the process of use, the whole refractory lining can be formed, which can effectively prevent the penetration of molten steel from the joints between the lining bricks to the inside of the bricks.

(2) excellent slag resistance. In addition to the role of graphite, spinel formed in the process of use can absorb FeO in slag to form a solid solution, while Al2O3 reacts with CaO in slag to form CaO-Al2O3 series compounds with high melting point, blocking pores and increasing melt viscosity to achieve the purpose of inhibiting slag penetration.

(3) high mechanical strength. Compared with mgo-c and al2o3-c refractories, aluminum-magnesium-carbonaceous refractories contain less graphite, generally ranging from 6% to 12%, so they have high bulk density, low porosity and high strength.

High alumina raw materials available super bauxite clinker, Ⅰ contour bauxite clinker, fused corundum, sintered corundum. Raw materials containing MgO can be used as electrofused magnesia or sintered magnesia. Carbon raw materials are mainly natural flake graphite, binder is generally used to synthesize phenolic resin, in addition to a certain amount of SiC, Al powder as antioxidant.

Despite the high grade bauxite clinker and Ⅰ bauxite clinker, fused corundum, sintered corundum can serve as a preparation of alumina magnesia carbon refractories containing alumina raw material, but because of bauxite containing high silicon oxide, adverse to the products of slag resistance. Compared with electric fused corundum, sintered corundum has smaller crystallization and more grain boundaries. The slag resistance of aluminum-magnesia carbon bricks made from it is not as good as the products made from electric fused corundum under the same conditions.

The raw materials containing magnesia mainly include electrofused magnesia and sintered magnesia. Compared with sintered magnesia, electrofused magnesia has thick crystallization, large bulk density and strong slag erosion resistance. Therefore, electrofused magnesia is generally added into non-aluminized magnesia carbon bricks, and it is mainly added in the form of fine powder, with the amount of addition generally less than 15%. If too much is added, too much spinel will be formed in the process of using the product. When the amount of magnesia is appropriate, the volume effect of spinel is favorable for blocking the pores.

Carbon raw materials are generally based on natural flake graphite. In order to avoid the low temperature oxidation of carbon materials and the large heat loss of molten steel caused by the high thermal conductivity of graphite, the amount of graphite is generally less than 10.

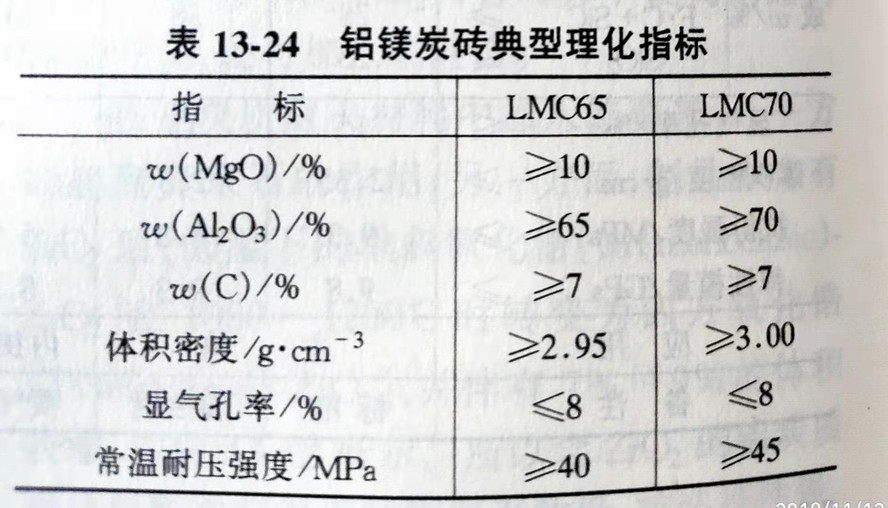

As with other carbon-containing materials, the binder is generally made of phenolic resin, and the amount added varies according to the different molding equipment, generally ranging from 4% to 5%. The production process of al-mg carbon brick is similar to that of magnesium-carbon brick. The physical and chemical indexes of typical al-mg carbon products are shown in table 13-24. The standard reference of resin-bonded al-mg carbon bricks is YB/T 165-1999.

When aluminum magnesium carbon brick is used, the slag first penetrates into the brick through the matrix with higher porosity in the decarburization layer, and reacts with Al2O3 in the brick selectively to generate low-melting products mainly C2AS. Under the action of slag at the service temperature, low-melting products such as C2AS and the surrounding high-melting spinel phase flow into the slag.

The velocity of slag infiltration can be expressed by poisson equation of liquid infiltration into porous materials:

X2=σrtcosθ/2η

Where, X-penetration distance;

r - stomatal radius;

η - melt viscosity;

σ - surface tension of melt;

θ - wetting Angle;

According to this equation, under certain ladle operating conditions, the slag penetration rate depends on the porosity of the lining brick, the slag wettability and the slag viscosity when the slag penetrates. Therefore, the low wettability of the brick to the slag can be ensured by controlling the graphite content and dispersion degree in the brick, so as to inhibit the slag penetration. At the same time, the content of Al2O3 in the brick can be increased to form CaO-Al2O3 compound with high melting point through the reaction with CaO in the slag, so as to block the pores and increase the melt viscosity, so as to inhibit the slag penetration and finally improve the performance of al-mg carbon brick.