Al2O3-SiC -C Brick

Al2O3-SiC -C brick is a non - burning carbon - containing composite refractory material with Al2O3, SiC and carbon as main components and phenolic resin as binder.

It is mainly used as the lining of torpedo type mixed iron car, iron water tank and other hot metal pretreatment equipment.

Before the middle of 1980s, the iron water tank was only a container for the storage of molten iron, and its lining was mostly made of clay bricks and pyrophyllite bricks, which had a good use effect, because the molten iron had no chemical erosion to the refractory materials. However, since the adoption of molten iron pretreatment technology, the service life of molten iron bag and the lining of torpedo mixed iron car has been greatly reduced, which is mainly caused by the serious erosion of refractory materials by various desulfurization, dephosphorization and desilication agents. Generally, CaO and CaC2 are used as desulfurizer, CaO-Feoxide-CaF2 is used as dephosphorization agent, and iron oxide is used as desilication agent. In addition, the spraying speed of these powders is very high, up to 600kg/min. Therefore, the lining of torpedo type mixed iron car and iron water tank is required to have excellent slag erosion resistance, thermal shock resistance and good mechanical erosion and wear resistance. High alumina refractories are not quickly eroded by limestone flux, but flake off easily. Therefore, graphite and SiC must be included in the refractories for torpedo iron mixer and iron water tank lining to improve their spalling resistance. Graphite can make the brick has high thermal conductivity, and can prevent slag penetration. SiC can form gaseous SiO or SiO2 in brick to protect graphite from oxidation. Therefore, al2o3-sic -C brick has excellent slag resistance and thermal shock resistance, as well as good erosion resistance and wear resistance. So far, al2o3-sic brick is the most ideal lining material for hot metal pretreatment container.

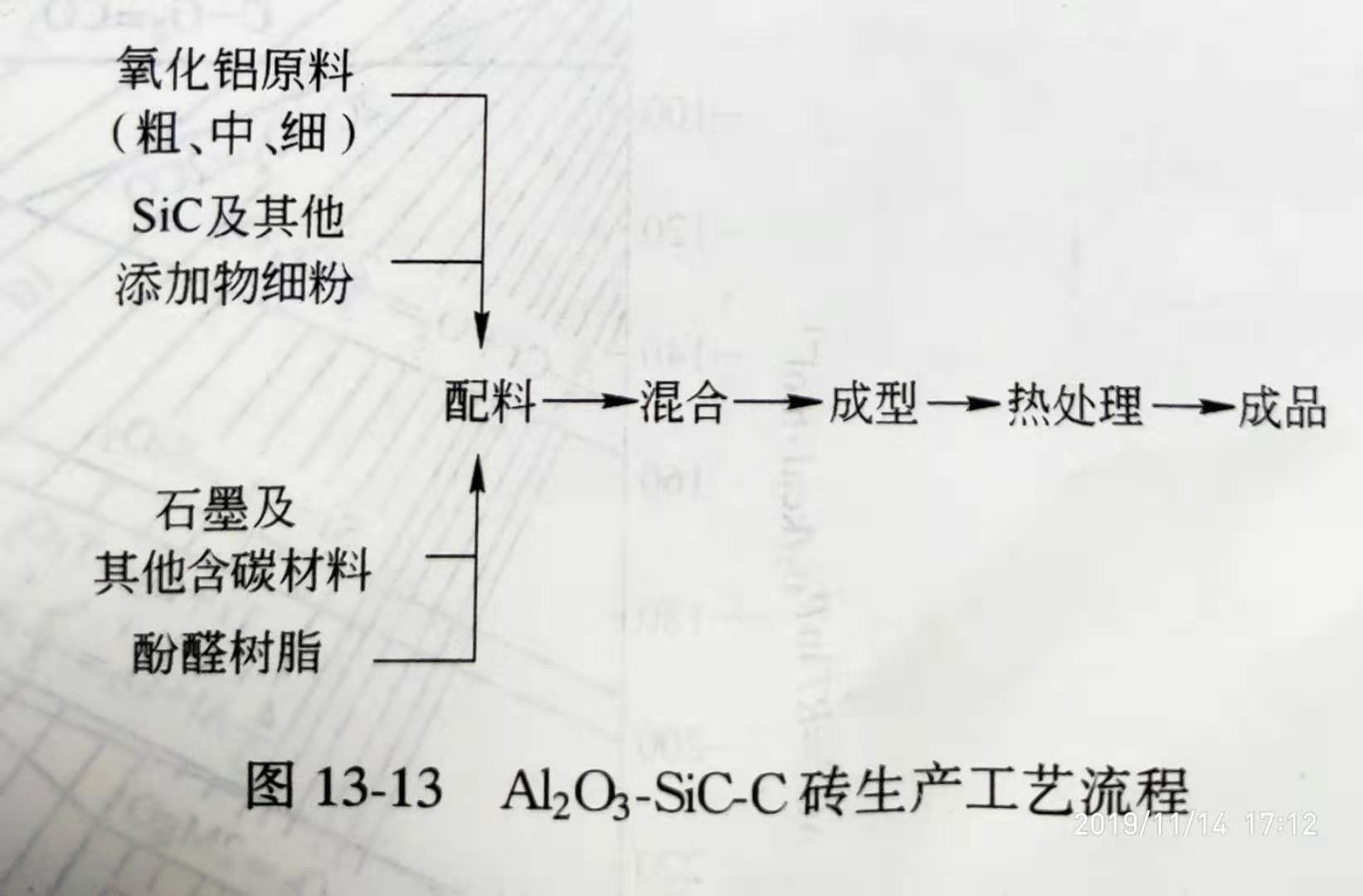

Production of al2o3-sic -C brick is mainly fused corundum, sintered corundum, bauxite clinker, andalusite, silicon carbide, graphite and other additives. In addition, a certain amount of electrofused magnesite can be added into the matrix to make the brick form spinel in the process of use, and have residual expansion property, improve the thermal strength, so as to enhance the corrosion resistance of the brick. The addition of a certain amount of beta-si3n4 into the matrix helps to enhance the chemical stability of the brick under the dephosphorization condition, improve the impact resistance, thermal strength and wear resistance of the brick. The production process of al2o3-sic -C brick is shown in figure 13-13.

The main raw material of al2o3-sic -C brick is alumina. The results show that if the content of SiO2 is large, the melting rate of brick is large. Al2o3-sic -C brick with SiO2 content less than 6% is not easy to crack. The erosion loss is controlled by the aggregate grain boundary. The electrofused aggregate has large grain boundary but few grain boundary, while the sintered corundum has more grain boundary, and the slag is easy to penetrate and cause the loss of grain. The erosion rates of the two are respectively 8% and 35%.

Graphite materials for Al2O3 - SiC - C brick slag resistance and thermal shock resistance plays an important role, so the selection of graphite materials, should choose as far as possible impurities (SiO2, CaO, Fe2O3) content is lower, at the same time when using graphite is less than 150 purposes, the small and medium-sized brick porosity, good for high temperature strength, the uniform distribution and conducive to inhibit matrix partial oxidation and slag penetration.

SiC can inhibit the oxidation of carbon and react with CO to form SiO2 dense protective layer. SiC has high thermal conductivity and strong slag resistance, but Na2CO3 is easy to react with SiC to generate low-melting, 2Na2CO3+SiC=4Na+C+SiO2, and the oxidized products of SiC and CaO, CaF2 are also easy to generate low-melting feldspar or glass phase, the content of SiC depends on the appropriate selection of different parts. SiC with particle size less than 60 microns is introduced into al2o3-si-c brick, and oxidation can be inhibited when the treatment temperature is around 1300℃. Small particle size, obvious oxidation resistance, large particle size, good thermal shock resistance.

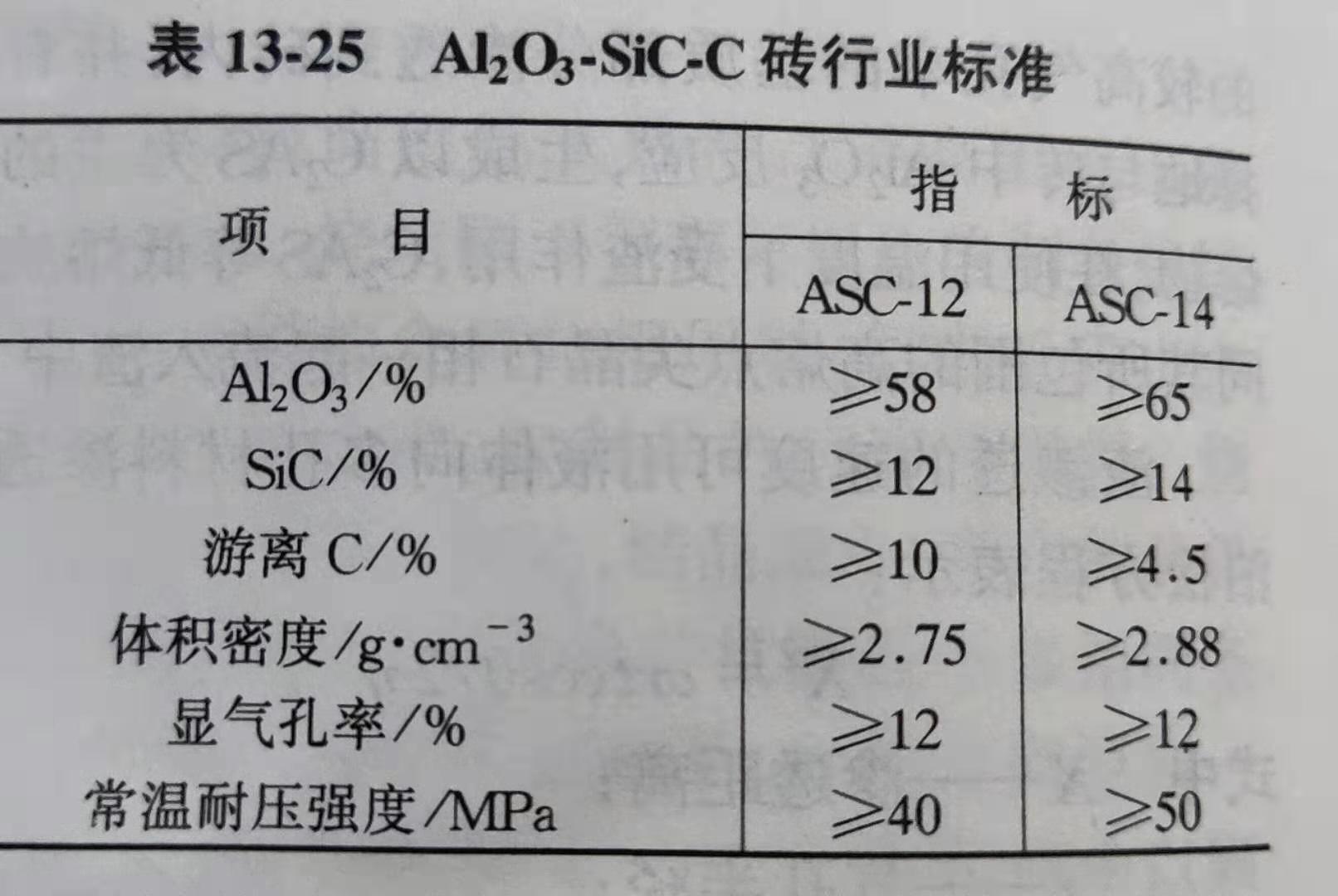

At present, the corresponding industry standard (YB/ t164-1999) for al2o3-sic -C brick used for hot metal pretreatment in China is shown in table 13-25.