Chromium Oxide Refractories

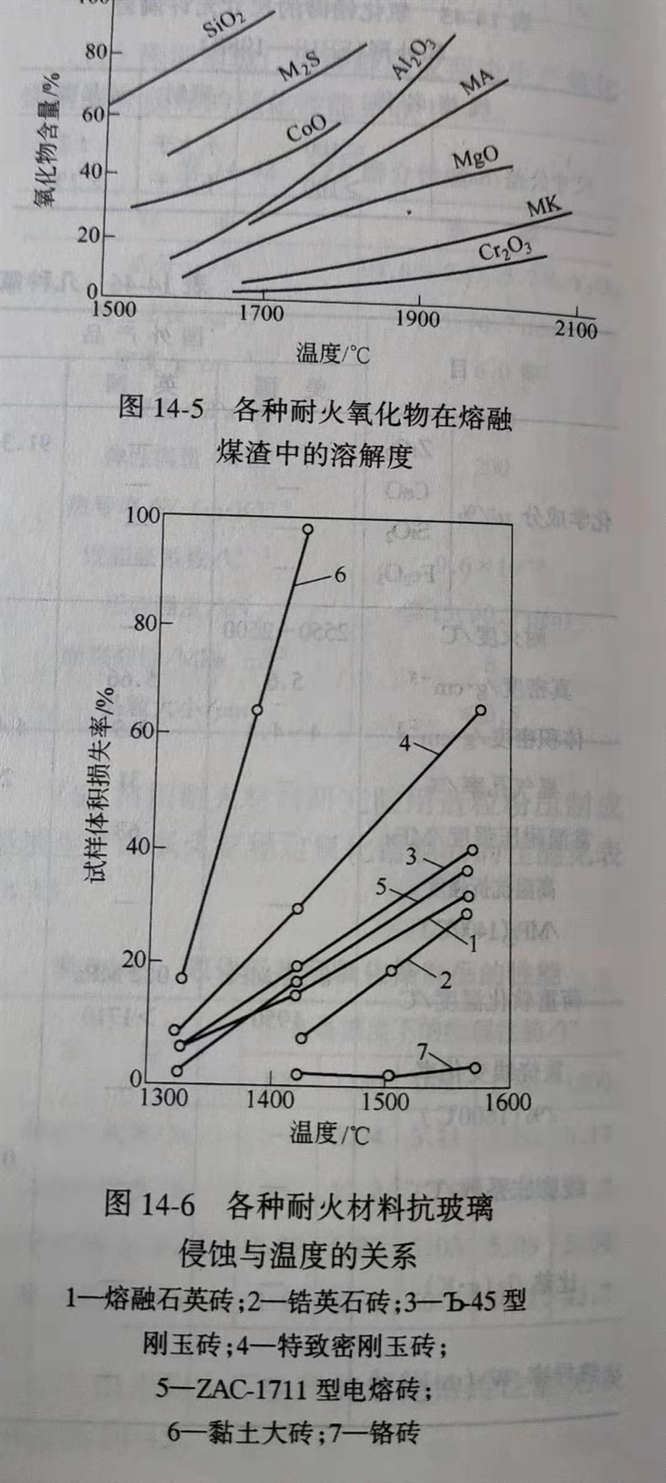

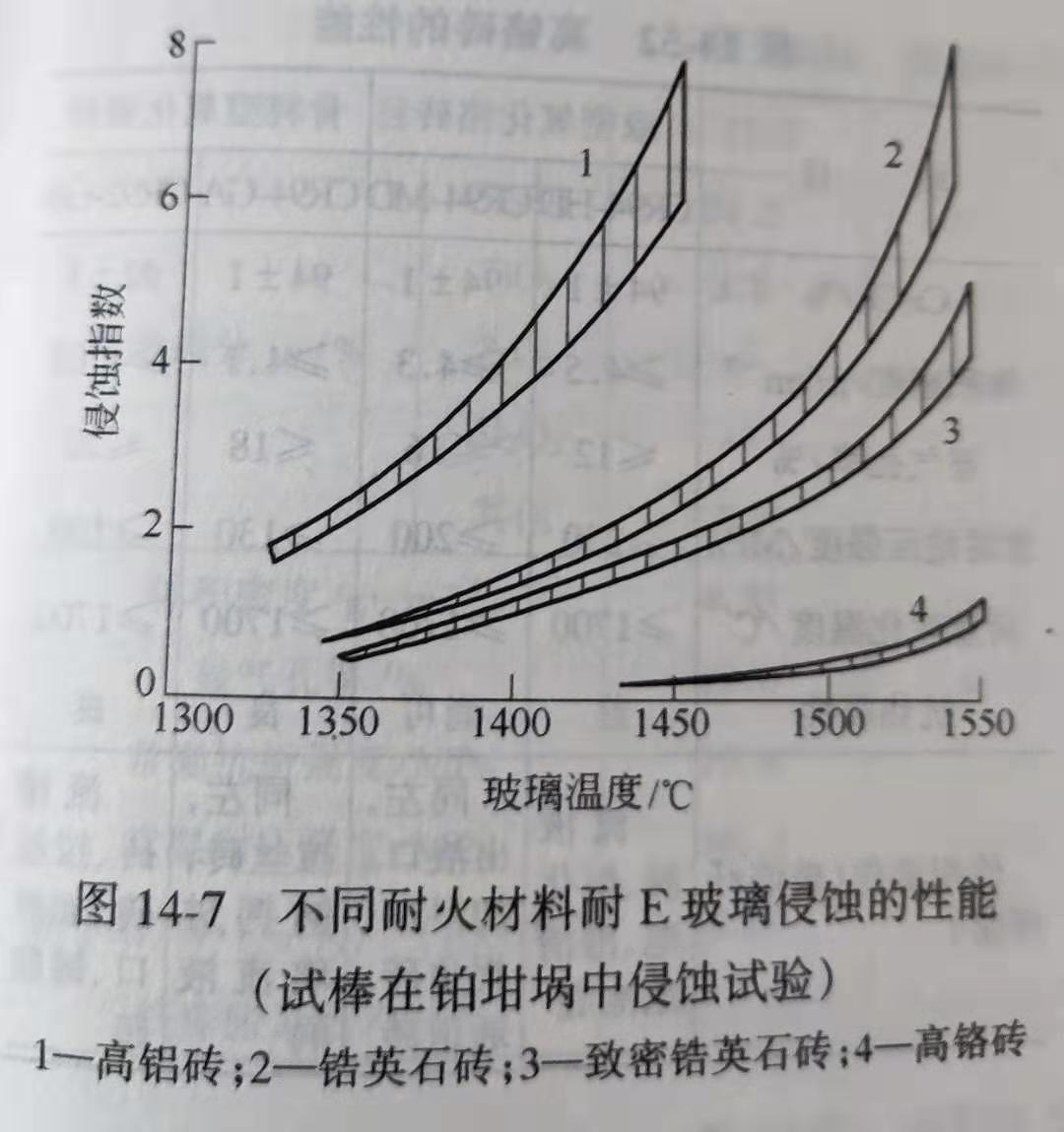

High chromium oxide refractories are excellent materials for resisting coal slag and liquid glass. High chromium oxide products are used as the main lining material in the large ammonia gasifier and the large glass fiber kiln. The service life is higher than other oxide products. The chemical erosion resistance of each oxide to coal cinder is shown in figure 14-5, and the erosion resistance of dense high-purity chromium oxide products to glass liquid is shown in figure 14-6 and figure 14-7.

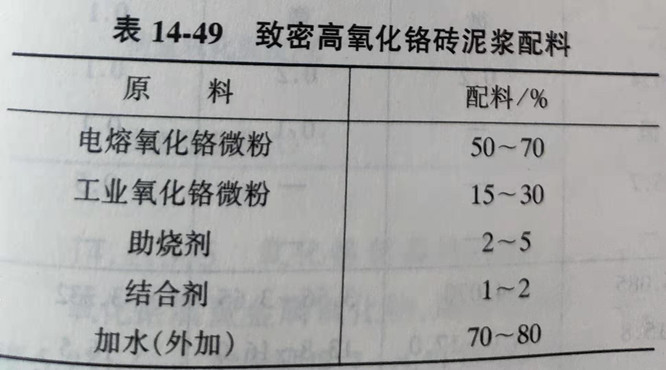

High chromium oxide products are produced from sintered or electrofused chromium oxide. The basic ingredients of high chromium products produced by using capacitive chromium oxide: electrodeposited chromium oxide 3~0mm,60%~70%, mixed fine powder 30% ~ 40%, plasticizer less than 1%, binder 2.5%~3.5%. It was formed on a 10MN friction press and fired in a high temperature kiln at 1600~1800℃ for 10 hours. Isostatic pressing was used to produce dense and high purity chromium oxide products. The dense high chromium oxide brick was prepared with electrodeposited chromium oxide powder as the main raw material, industrial chromium oxide powder and burning aid. The slurry batching is shown in table 14-49. According to the above mentioned ingredients, a high speed mud mixer is used to make the flowing mud. In the pressure granulation spray dryer granulation powder strength less than 0.3 mm, bulk density 1.1~1.3g/cm3, residual water less than 0.5%. In isostatic press by 140~200MPa pressure molding, blank size (1200~1500) mm× (500~600) mm× (400~500) mm. The products were fired in a weak reducing atmosphere at 1700~1800℃ and kept warm for 20~30h. The total burning time is 15 to 20 days. The main crystal phase of the product is chromium oxide, and there are various forms of continuous solid solution and finite solid solution. , between the main crystal phases, and between the main crystal phase and the solid solution. The production of chromium-oxide brick by electromelt casting, the varieties of chromium-oxide brick are high chromium-chromium brick, chromium-aluminum brick and chromium-aluminum zirconium brick. The melting temperature can be reduced by adding an appropriate amount of other oxides to the batching of various fused bricks. The glass phase generated in the structure of the cast brick can prevent the cracking of the product caused by the volume change in the process of slow cooling. Japan also introduces a crystallization and alpha calcium chromate (alpha CaO Cr2O3), and contains 0.3% ~ 15% of alkali metal oxide refractory materials, and has good thermal shock and erosion resistance, as a kind of CaO, a mixture of Cr2O3 and Li2O, when heated to 2400 ℃ after the casting solidification, can be made into CaO26.3 %, Cr2O373. The 0% %, LiO0.7 fused cast brick, the main crystal phase CaO Cr2O3, longitudinal elastic modulus is less than 6 x 104 mpa fused cast brick.

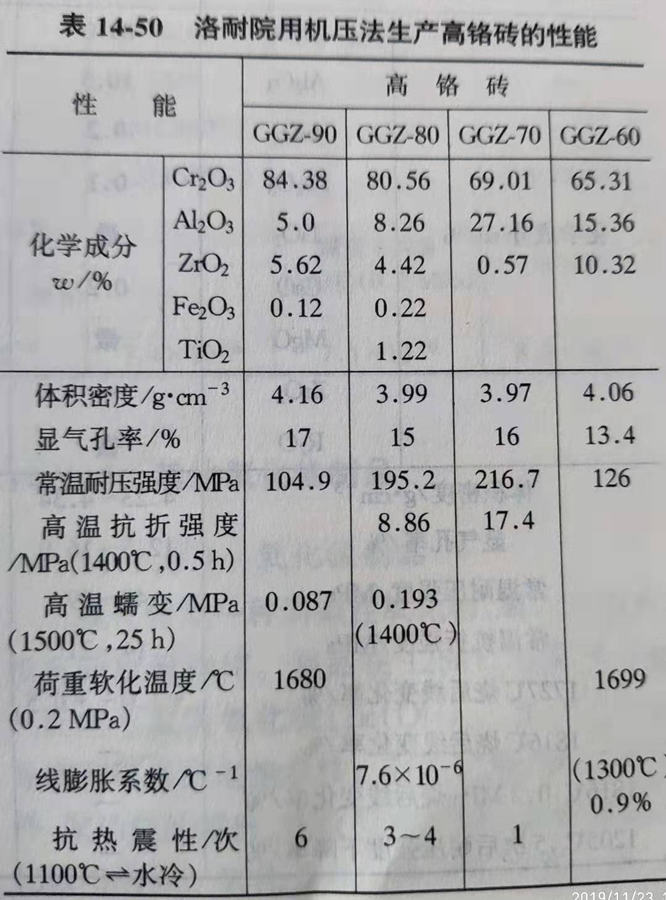

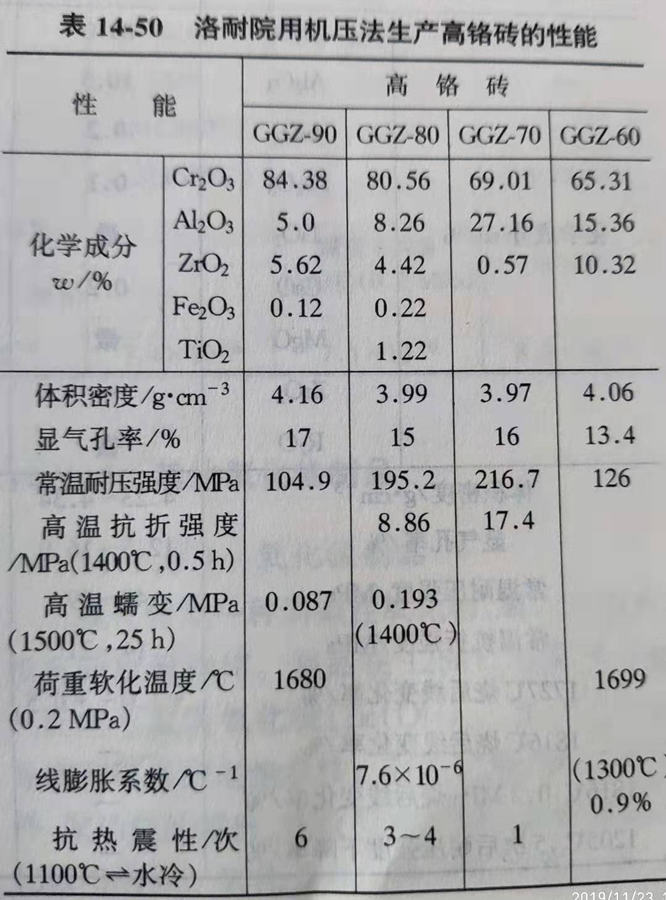

(1) physical and chemical properties of high chromium brick made by press molding in luoyang refractories research institute are shown in table 14-50.

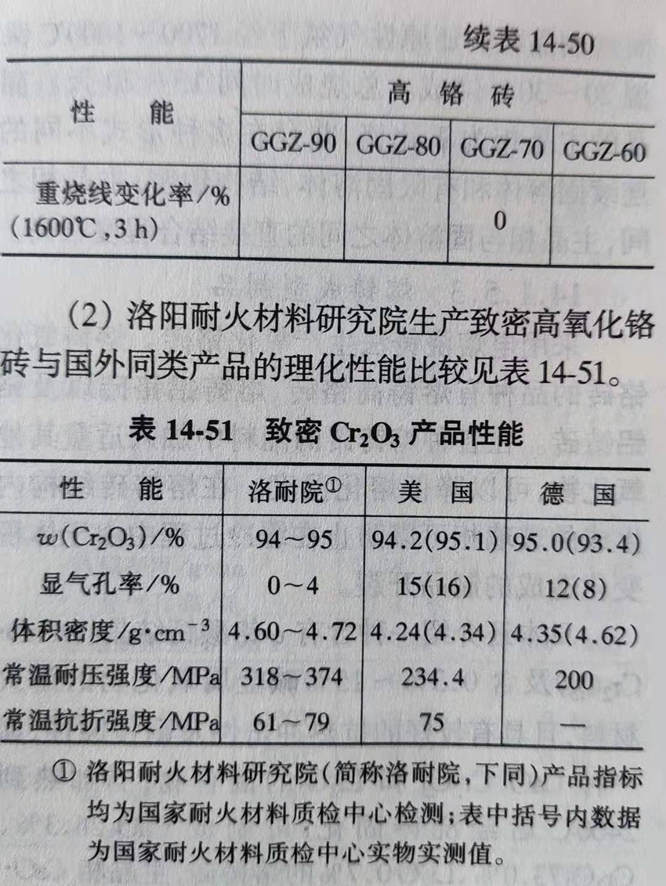

(2) the physical and chemical properties of dense high chromium oxide bricks produced by luoyang refractory research institute are compared with similar foreign products, as shown in table 14-51.

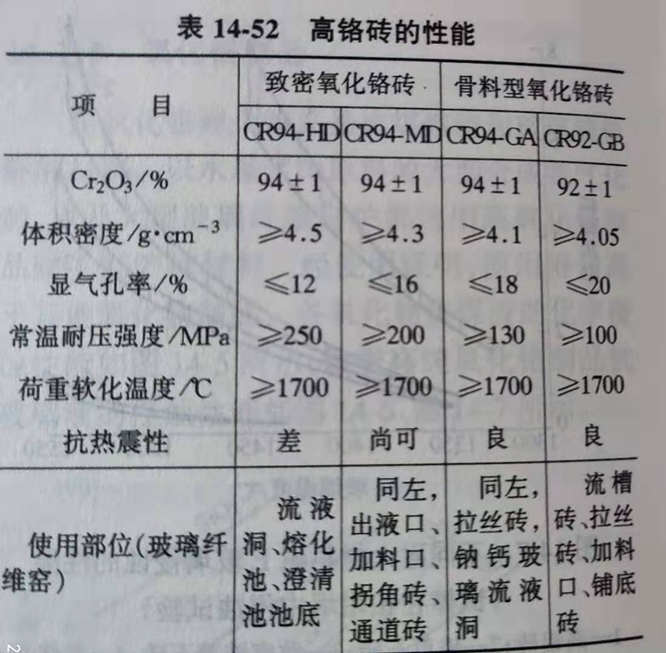

(3) physical and chemical properties of compact chromic oxide bricks and aggregate chromic oxide bricks produced by guangdong lingnan factory are shown in table 14-52.

(4) production of high chromium bricks by several foreign companies:

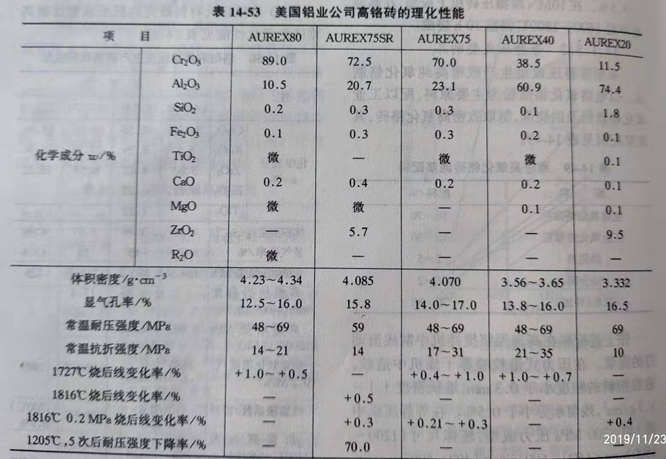

(1) the physical and chemical properties of the machine-pressed high chromium bricks from Alcoa are shown in table 14-53. The physical and chemical properties of the isostatic pressed high chromium bricks from kohart are shown in table 14-54.

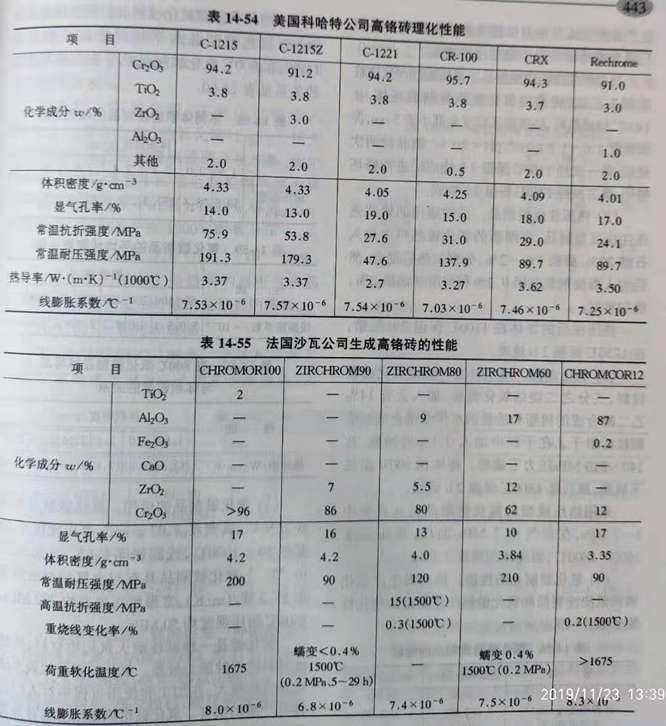

(5) the physical and chemical properties of various high chromium bricks produced by France sava company are shown in table 14-55.

Chromium oxide heavy metal oxide, melting point 2350℃, true density 5.23g/cm3, mohs hardness 7-8, linear expansion coefficient (℃-1) 9.0×10-6, thermal conductivity 2.6~ 2.8w /(m·K).

Chromium oxide is a neutral refractory material, is a good acid, alkali erosion resistant material. Because chromium oxide is a good material that can resist the erosion of coal slag and glass liquid, it has achieved remarkable results in the application of large ammonia gasifier for CWS and large glass kiln and glass fiber kiln.