Oxide Products

Beryllium oxide is a weakly alkaline oxide of hexagonal system without homogeneous isomers. The product is easy to react with water vapor at 1250℃ to produce beryllium hydroxide [Be (OH) 2], which has great thermal conductivity and strong electrical insulation, and can Be made into electronic parts, engine parts, nuclear reactor ceramic materials and oxygen-hydrogen beryllium crucible. Beryllium oxide, a kind of toxic oxide, has a great impact on the health of production and use personnel. Isolate the operation and take strict protective measures.

(1) mud casting molding products, acid mud casting molding process, high purity beryllium oxide raw materials into the body, at 1400℃ burning mature material, after fine grinding particle size less than 5 muon, mud density 1.6~1.8g/cm3,pH=3~4. The product was fired twice, the first time after being fired at 1150℃ for 2h, and the second time after being fired at 1500℃ for 2h.

(2) hot injection molding products. Adopt the universal wax paste hot injection molding products, add 20% paraffin wax, 1% ~ 2% beeswax in the finely grinding beryllium oxide clinker, heat and mix, then add alumina 0.2% burn-aid and lubricant oleic acid 2%, mix and exhaust.

After hot pressing, the preform was insulated at 1100℃ for 2h and dewaxed at 1750 for 2h.

(3) press products. 1/3 sintered beryllium oxide granules and 2/3 sintered beryllium oxide powders were prepared and dried by adding a resin containing 14% glycol synthesis and appropriate amount of water as the binder. Add 0.1% oleic acid to dry material and shape it at 140~210MPa. The billet was degreased at 500℃ and finally burned at 1800℃ for 2h.

The hot-pressed beryllium oxide products are pressurized at 1~2MPa in vacuum and 7MPa in air with a hot-pressed temperature of 1600~1800℃ and a volume density of 2.98g/cm3.

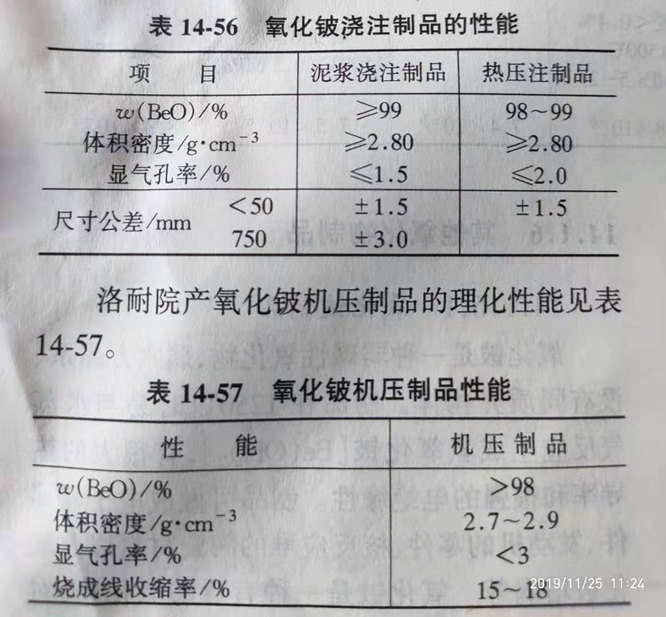

(4) properties of beryllium oxide products. Physical and chemical properties of beryllium oxide mud casting products and beryllium oxide hot injection products produced by lornay institute are shown in table 14-56.

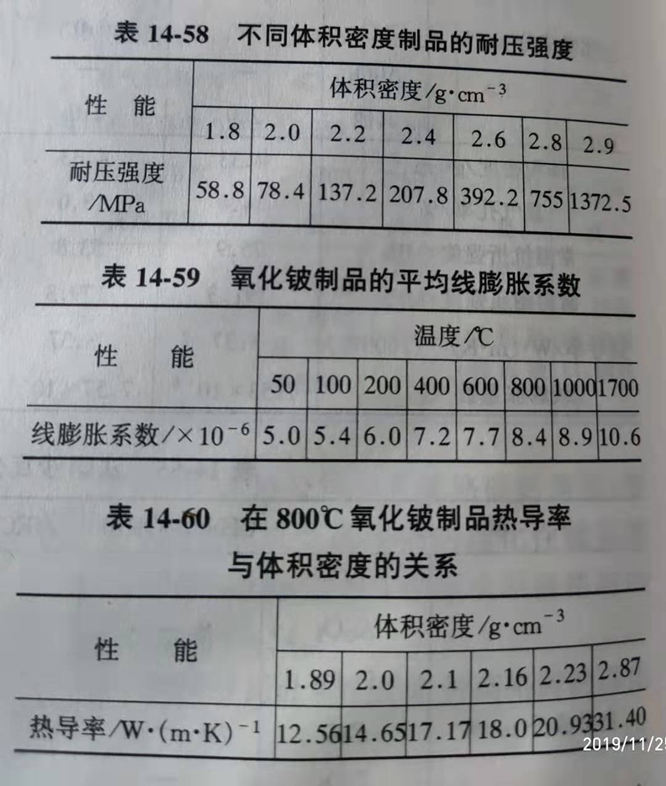

The compressive strength of beryllium oxide products with different volume densities is shown in table 14-58, the mean linear expansion coefficient of beryllium oxide products is shown in table 14-59, and the relationship between thermal conductivity and volume density of beryllium oxide products at 800℃ is shown in table 14-60. Physical and chemical properties of the manufactured beryllium oxide were shown in table 14-57.

(5) application of beryllium oxide products. The melting point of beryllium oxide products is 2550℃, true density is 3.03g/cm3, mohs hardness is 9, temperature is 50~1000℃, linear expansion coefficient (5.1~8.9) ×10-6℃-1, beryllium oxide has thermal conductivity of 25.2W/ (m·K) similar to that of metal, and compressive strength of about 790MPa at room temperature,1600℃

When, the compressive strength is about 50MPa.

Beryllium oxide is an alkaline refractory oxide material with poor erosion resistance. The biggest disadvantage of beryllium oxide products is that they are very toxic and can cause serious damage to human body in the process of processing and use. Beryllium oxide crucible is a container for smelting rare metals and high purity metals such as beryllium, platinum and vanadium, as well as neutron moderators and anti-radiation materials for atomic reactors, as well as high-frequency, insulation and heat dissipation devices used in the electronics industry.

Yttrium oxide melting point of 2410℃, true density of 5.05g/cm3 is an excellent special refractory. It can be made into high temperature furnace, window glass, transparent tube and cast titanium material.

The United States patent describes the dense transparent yttrium oxide ceramic products are made of materials containing yttrium oxide, 99.9%, with particle size of 0.4~10 microns, forming pressure of 300~1200MPa, which are fired twice, the first time in vacuum at 2150~2230℃, the second time in hydrogen gas at 2200~2300℃. The product can reach more than 98% of the theoretical density. The transparency of the product is up to 80% in the wavelength range of 1~7 microns.

Another American patent introduces the addition of 6%~14% (mole fraction) lanthanum oxide (La2O3) in yttrium oxide, which is made into tubular or round slab body with pressure greater than 240MPa. The body is kept in air at 1000℃ for 1h, and then fired in a controlled atmosphere. Oxygen partial pressure in atmosphere during sintering should be low enough to prevent contamination of products. The product is basically transparent high-density polycrystal, which is a kind of well-shaped transparent ceramic suitable for bulb. Titanium oxide products

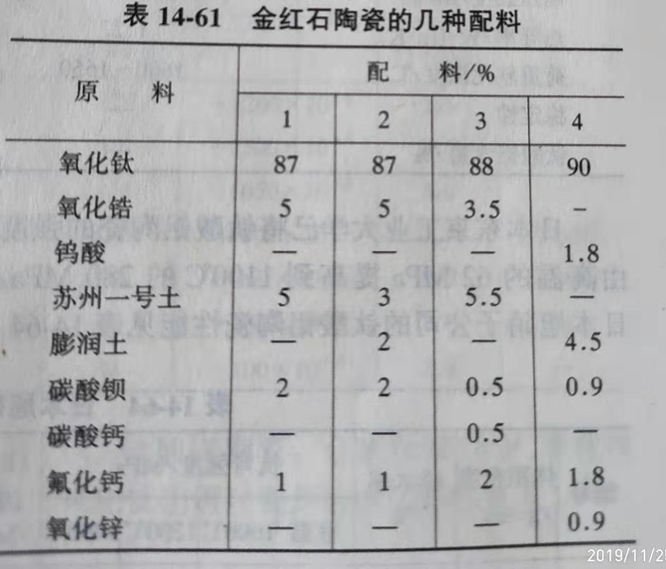

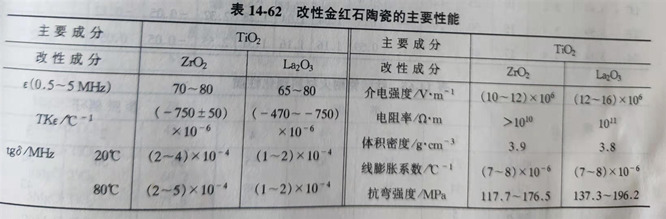

(1) rutile (TiO2) products. Rutile has a melting point of 1840℃ and true density of 4.26g/cm3. It is a square crystal, stable from room temperature to melting point. Rutile ceramics is titanium dioxide as the main raw material, adding bentonite as a plasticizer, adding zirconia as a burning agent. The ingredients of rutile ceramics are shown in table 14-61, and the main properties of modified rutile ceramics are shown in table 14-62.

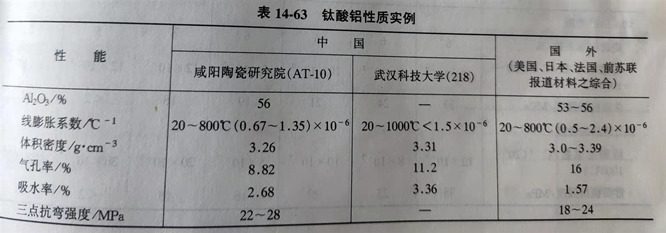

(2) aluminum titanate products. Aluminum titanate is a kind of low-expansion material, whose composition ratio (mol) Al2O3:TiO2 is 1:1, mass ratio Al2O3:TiO2 is 56% : 44%, melting point is 1860℃. Aluminum titanate can be used as lining material, heat exchanger, catalyst honeycomb support, kiln furniture and temperature protection tube.

When the ceramic crucible of aluminum titanate was developed by xianyang ceramic research institute, the effect of adding 4-valence silicides into the synthesis of aluminum titanate was the best, which could promote the synthesis effect and improve the strength of the product.

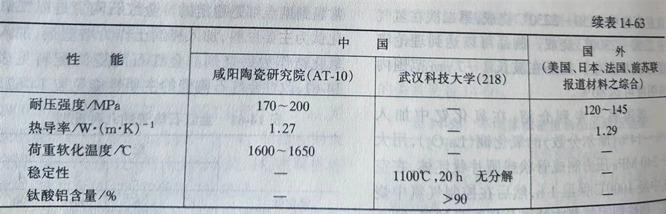

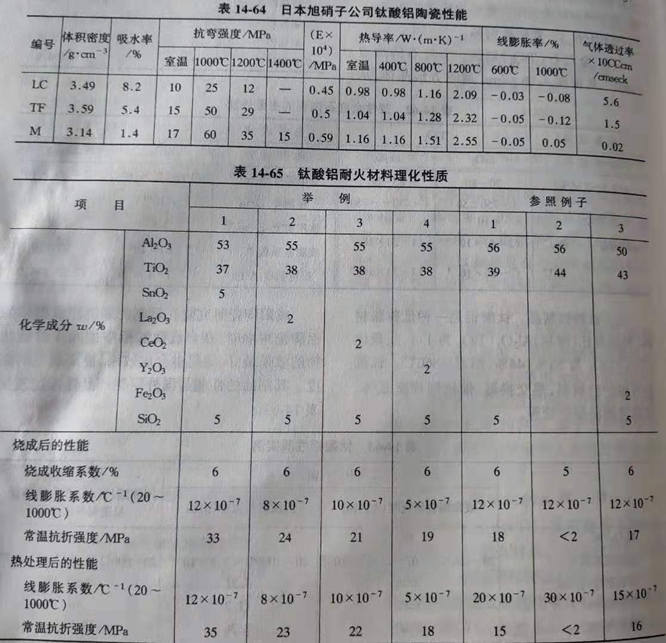

Tokyo university of technology has raised the strength of aluminate ceramics from 62MPa at high temperature to 280MPa at 1100℃. The properties of aluminum titanate ceramics of asahi glass subsidiary of Japan are shown in table 14-64. In America, pure oxide is used as raw material. After granulation, it is formed by isostatic press with a pressure of 100MPa. It is heated at 1530℃ for 4h. The physical and chemical properties of aluminum titanate refractory are shown in table 14-65.

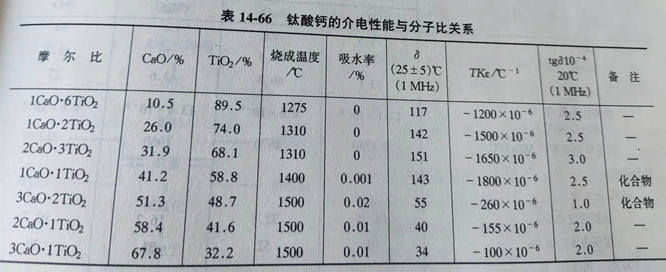

Calcium titanate ceramics were prepared with 99% calcium titanate clinker and 1% zirconia. Adding a small amount of zirconia to the mix can reduce the sintering temperature and enlarge the sintering range. (3) calcium titanate ceramics. The content of titanium dioxide in the synthesis of calcium titanate increased and the synthesis temperature decreased. The relationship between dielectric properties and molecular ratio of calcium titanate is shown in 14-66.

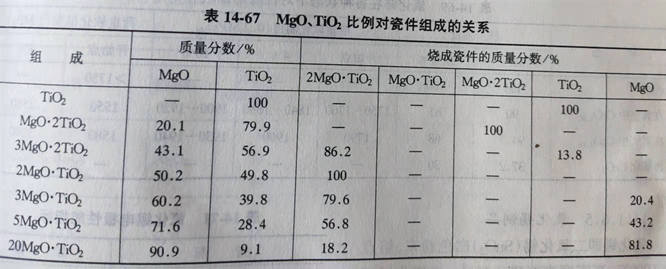

(4) magnesium titanate ceramics. In the synthesis of magnesium titanate, the influence of the proportion of magnesium oxide and titanium dioxide on the composition of porcelain is shown in table 14-67.

When calcium titanate (CaTiO3), strontium oxide (SrO), barium oxide (BaO) or lanthanum oxide (La2O3) are added into magnesium titanate ceramics, the dielectric constant and temperature coefficient of magnesium titanate ceramics can be adjusted.

Cerium oxide (CeO2) belongs to fluorite cubic crystal system, melting point is 2725℃, true density is 7.30g/cm3 mohs hardness is 6. Cerium dioxide can be used as heating element, light source, abrasive, abrasive, etc., can improve efficiency 1~2 times.

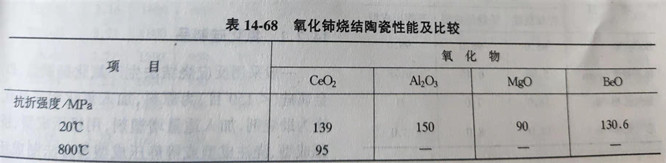

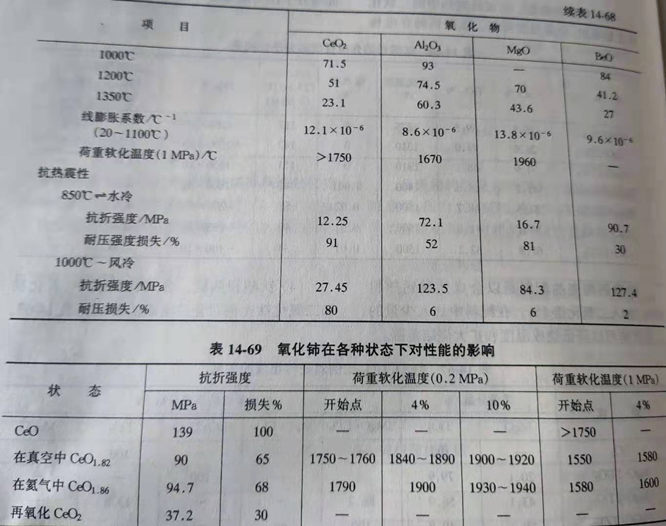

The performance of the sintered cerium oxide ceramics and its comparison with other oxide ceramics are shown in table 14-68. The influence of cerium oxide on the properties of the products in various states is shown in table 14-69.

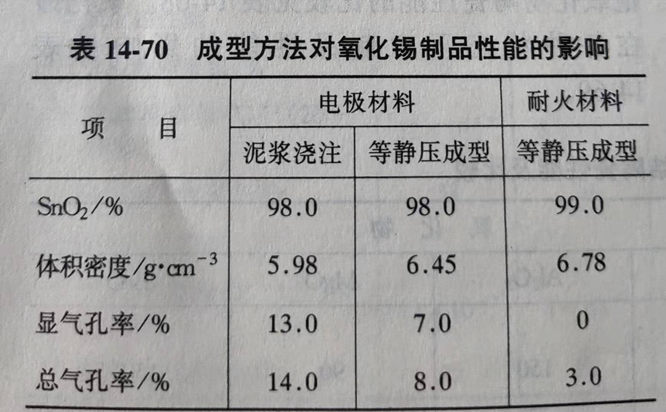

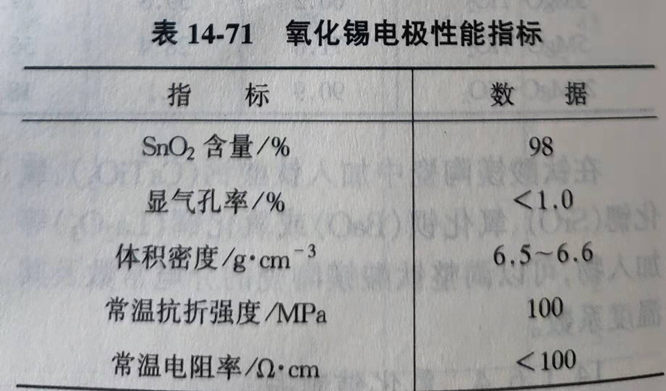

SnO2 is a white powder with a melting point of 1900℃ and true density of 6.95g/cm3. Tin oxide can be used as electrode material of electrofused lead glass. The properties of tin oxide products produced by various molding methods are shown in table 14-70, and the properties of tin oxide electrode products produced by guangdong lingnan factory are shown in table 14-71.