Silicon Nitride, Boron Nitride

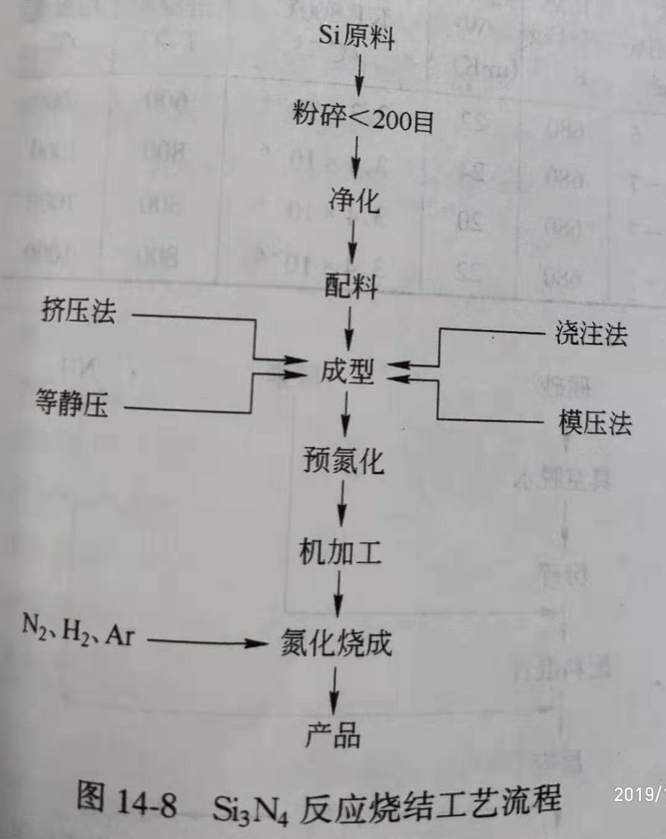

Silicon nitride products, generally adopt reaction sintering process to produce silicon nitride products, take silicon metal (less than 150 mesh) as raw material, add alumina or magnesium oxide as sintering aid, add an appropriate amount of plasticizer, press molding, extrusion molding, pouring molding or isostatic pressure molding method into the billet, reaction firing in the nitrogen-protected furnace. The SiN4 reaction sintering process is shown in figure 14-8.

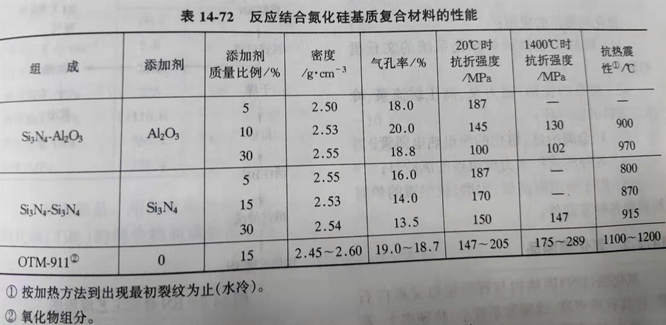

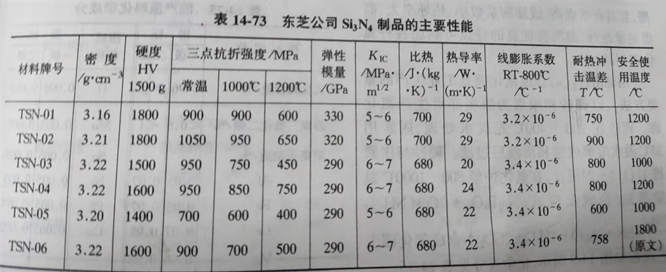

Another reaction combined Si3N4 products are made of synthetic Si3N4 (Si3N4) as the aggregate, silicon metal powder as the base material and other additives by pressing and other methods, and fired at 1400~1500℃ in the nitrogen-protected electric furnace. The properties of several foreign reactions combined Si3N4 products are shown in table 14-72. Main properties of silicon nitride products produced by Toshiba are shown in table 14-73.

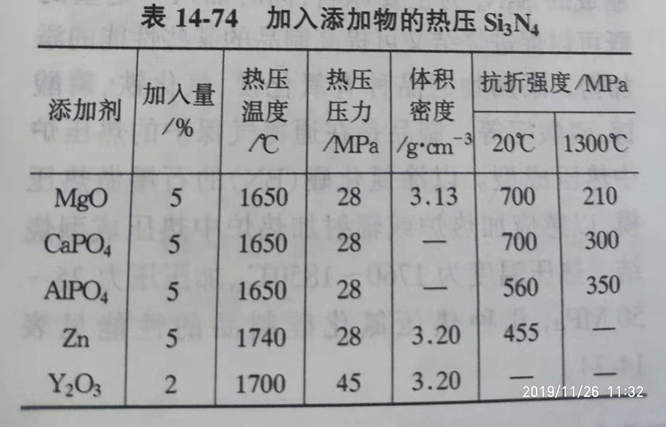

Hot pressing Si3N4 is the main raw material of Si3N4. At the same time, a certain amount of additives can not only promote sintering, but also improve some properties of the product. The variety of additives are magnesium oxide, iron oxide, gallium phosphate, aluminum phosphate and so on. Products are hot-pressed in a nitrogen-protected hot-pressed furnace. The graphite coated with boron nitride (BN) is used as hot pressing die to be pressed into sintering in induction furnace or radiation furnace. The hot-pressing temperature is 1760~1850℃ and the pressure is 25~50MPa. The properties of several hot-pressing si3n4 products are shown in table 14-74.

Application of silicon nitride products:

(1) venturi bushing for fluidized bed furnace purification system in sulfuric acid industry;

(2) porcelain shaft of acid pump, magnetic pump, high-pressure slow-flow pump, sealing ring of refrigerating compressor;

(3) thermocouple tubes for light metal smelting and melting;

(4) the sand sink mouth of water cyclone in various washing and dressing plants;

(5) used for furnace lining materials and various parts that require high temperature resistance, wear resistance and thermal shock resistance.

Boron nitride (BN) is similar to graphite, also known as white stone ink, and has the characteristics of high melting point, small linear expansion coefficient, high thermal conductivity, high temperature insulation, good lubrication, can be made into various boron nitride products.

Synthesis of boron nitride from boron oxide (B2O3) is an important process in industrial production.

Borax and urea can also be used as raw materials to produce boron nitrous oxide. The borax is dehydrated at 200~400℃, urea is dissolved in warm water at 35℃ and then filtered. Borax and urea are mixed in the nitriding furnace at a temperature of 800~1000℃ according to 1: (1.5~2).

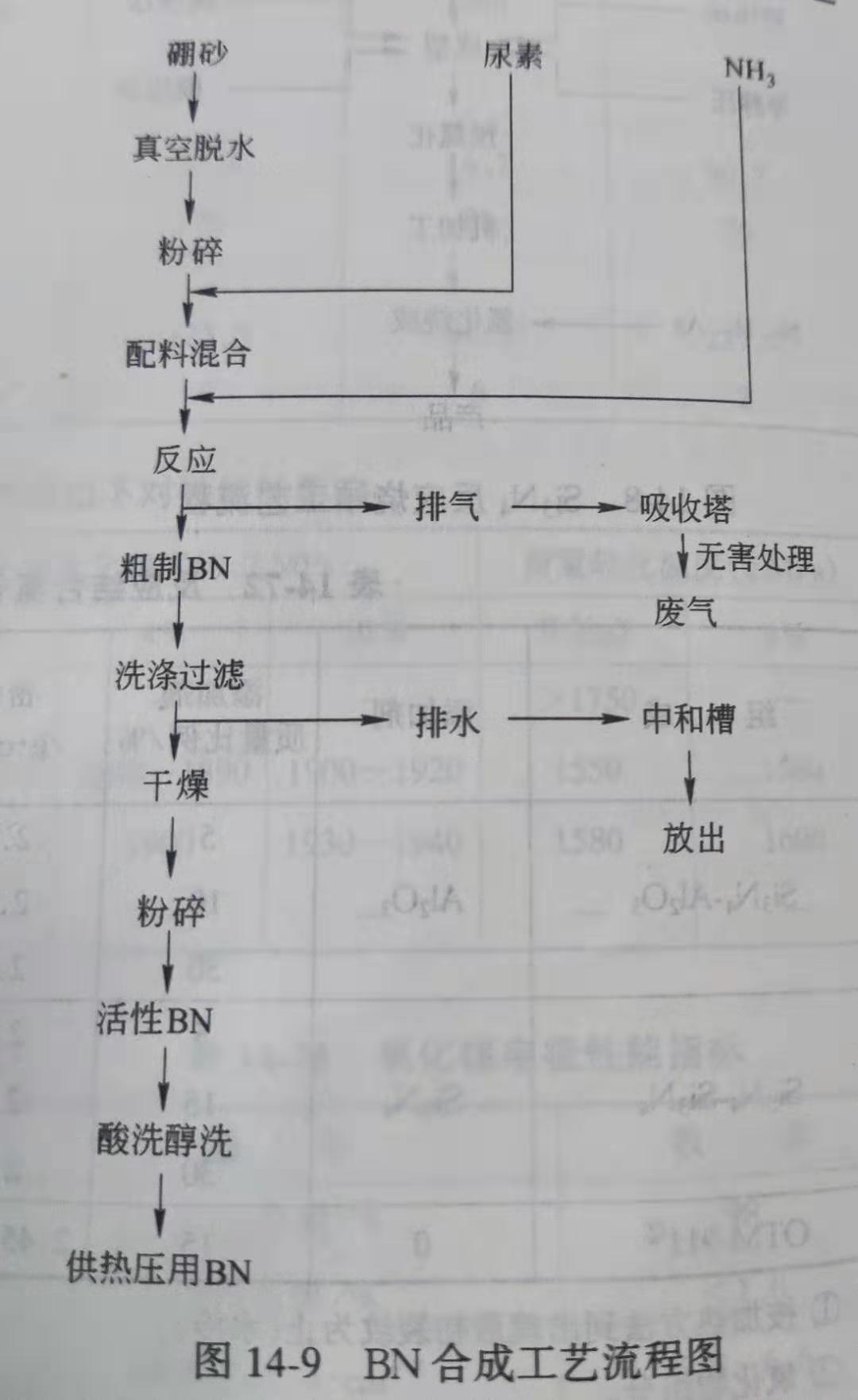

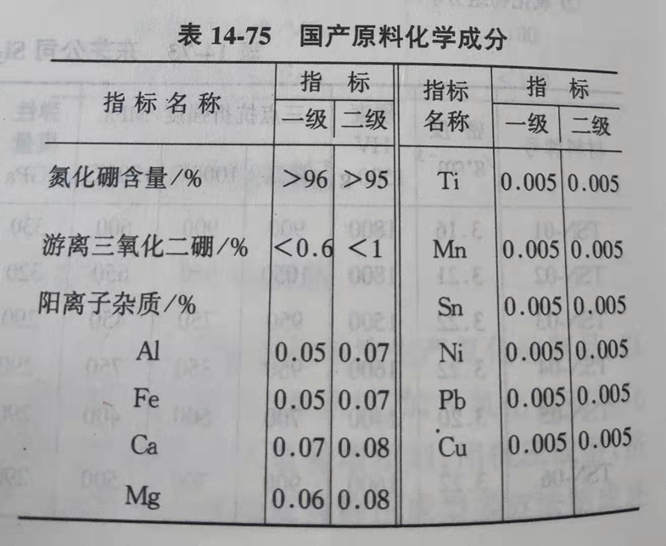

Na2B4O7 co (NH2) 2 + 2 nh3 ⊿ 4 bn co2 + Na2O + 4 h2o + 2 write synthesis of boron nitride process as shown in figure 14-9, chemical components are shown in table 14-75.

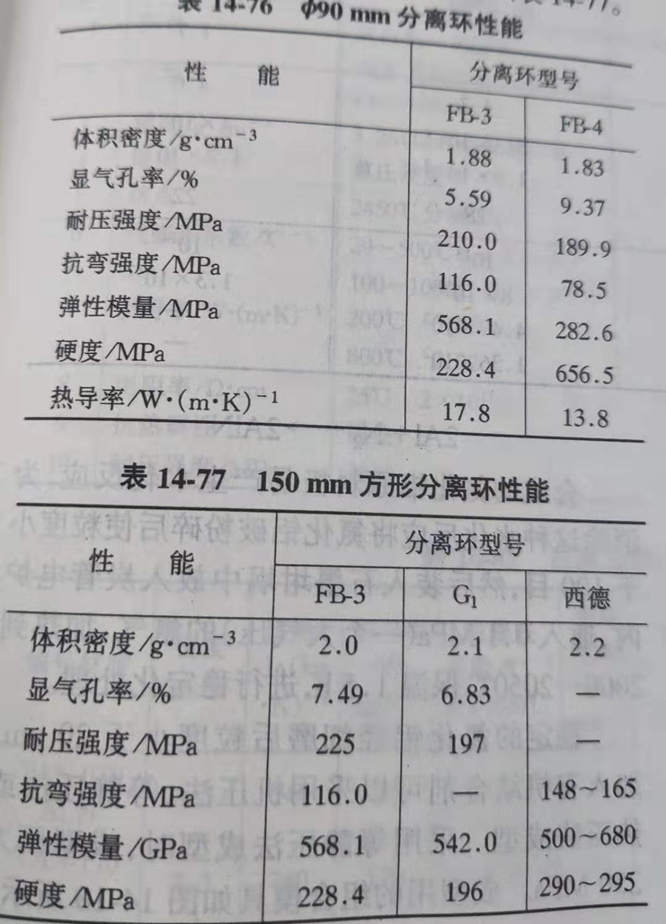

(1) hot-pressed boron nitride productsHot pressing process of boron nitride products: ɑ - nitride boron doping - mixing - preloading molding - pretend to hot-pressing sintering, plastic processing and finished products. Table 14-76 and table 14-77 show the performance of boron nitride separation ring in continuous casting at the production steelmaking level of Beijing iron and steel research institute.

(2) conductive products. With boron nitride zirconium boride (ZrB2) or a mixture of titanium boride (TiB2) made of composite products, has the opposite of boron nitride electrical, boron nitride and zirconium boride is similar to graphite conductive composite products, and strength to several times higher than graphite, metal corrosion resistance, good thermal shock resistance, mechanical processing, using temperature is 2000 ℃. Can be made into melt or molten metal evaporation of the container. Boron nitride zirconium boride and products performance: the volume density of 2.9 ~ 3.4 g/cm3, show porosity is less than 6%, the resistivity of 2 ~ 50 Ω cm, linear expansion coefficient (℃ - 1) (4 ~ 6) x 10-6, thermal conductivity is 20.58 W/m K, normal temperature 250 ~ 700 mpa, crushing strength flexural strength of 90 ~ 150 mpa.

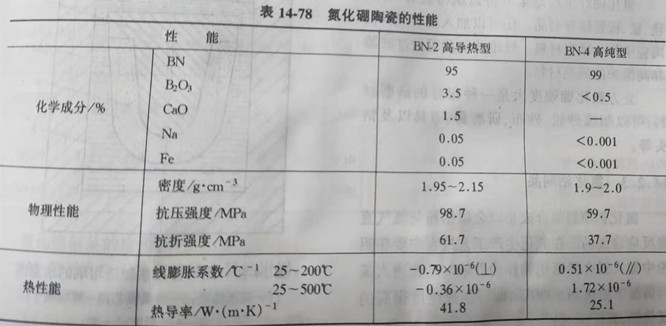

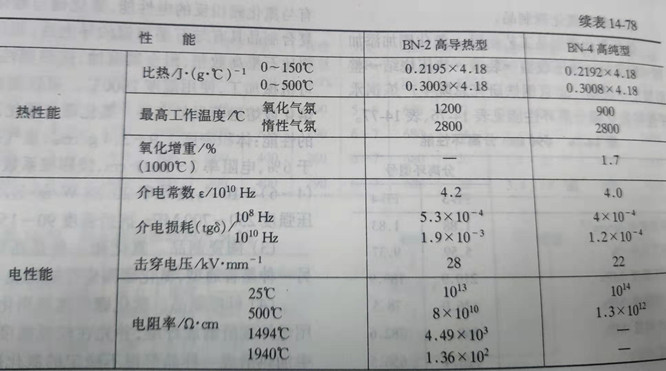

(3) ceramic products. Boron nitride is a type of high thermal conductivity, the other type is the ordinary type, boron nitride ceramics performance boundary table 14-78.

(4) fiber products. Boron nitride fiber is made of boron anhydride matrix fiber with chemical method, and heating in low temperature nitrogen formed a kind of crystal shape is very unstable, boron nitride fiber to heated to above 1800 ℃ in ammonia or nitrogen nitriding processing, made of boron nitride fiber physical and chemical properties: BN is more than 99%, the volume density of 1.8 g/cm3, fiber 5 ~ 7 microns in diameter, fiber length 50 ~ 380 mm, the tensile strength of 1400 mpa, stretching rate 2% ~ 3%, the modulus of elasticity (10 ~ 70) x 103 mpa.

(5) cubic boron nitride crystal. Cubic boron nitride can be made from hexagonal boron nitride at more than 1500℃ and 60,000-100,000 atmospheres (6000~10000MPa). Cubic boron nitride has a hardness of 9.8 to 9.9, second only to diamond, and is used to make tools that can cut hard and tough steel at temperatures up to 1500 to 1800℃.

(6) application of boron nitride products. Powdered boron nitride is a good solid lubricant.

(7) hot-pressed boron nitride can be made into high-temperature insulation seals for plasma welding tools, insulated radiator sleeves for explosion-proof motors in underground coal mines, thermal shielding elements for rocket combustion Chambers and spacecraft.

(8) boron nitride ceramic crucible for melting metal, thermocouple protection tube, conveying pipeline, evaporation of liquid metal containers of metal, casting copper and cast glass mould, CBN monocrystal smelting, containers of gallium arsenide and gallium nitride semiconductor, semiconductor device encapsulated cooling floor, transposition of the cooling rods, traveling wave tube radiator pipe, the micro glass window, reactor control rod, infrared filter plate, sodium lamp pipe lining, etc.

(9) boron nitride fiber is soft in texture and can be woven into clothing and made into felt, blanket, board, tube and other products. Can also be added to glass, plastic, ceramic as reinforcement materials, fibrous products, can be used as a filter and high temperature furnace insulation material.

Cubic boron nitride hardness is a good grinding material, can be made into grinding wheel emery cloth, grinding paste, tools and drill bits.