Aluminum Nitride, Titanium Nitride Products

The synthesis of aluminum nitride material is a direct reaction between aluminum powder and nitrogen. Alkali fluoride should be added to aluminum powder as flux in the nitriding process. Under the condition of filling nitrogen and heating it to 1000℃, aluminum nitride with high purity can be made. The reaction formula is as follows:

Al + N2 - > 2 aln

The synthesized raw material of aluminum nitride is very easy to produce hydration reaction. In order to eliminate such hydration reaction, the particle size of aluminum nitride is reduced to less than 100 mesh after breaking and crushing. Then, it is put into a graphite crucible and put into a carbon tube furnace, which is filled with argon gas of 0.1MPa(one atmosphere).

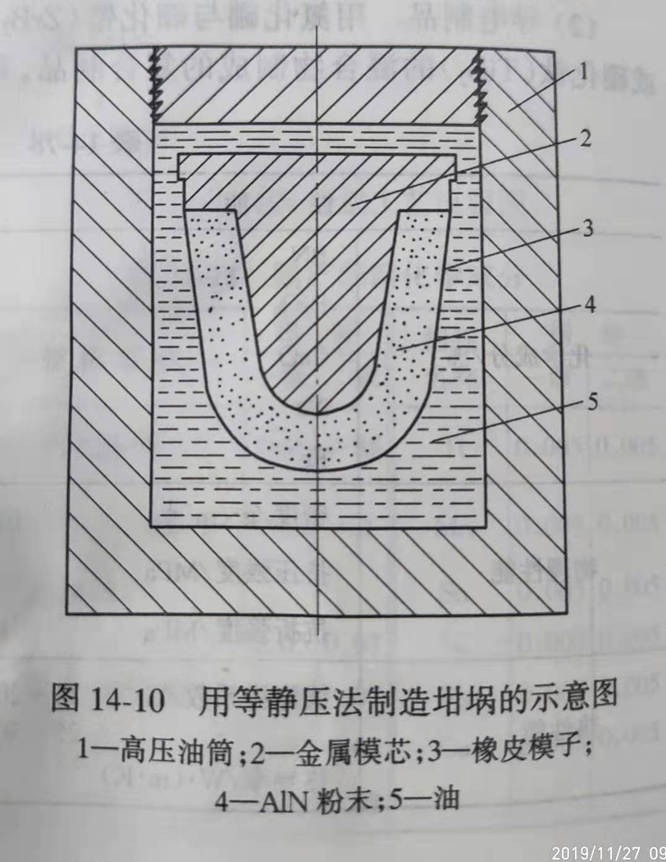

The particle size of stable aluminum nitride after fine grinding is less than 20 microns. When forming by isostatic pressure, the molding pressure is 250MPa. The combined mould for forming is shown in figure 14-10.

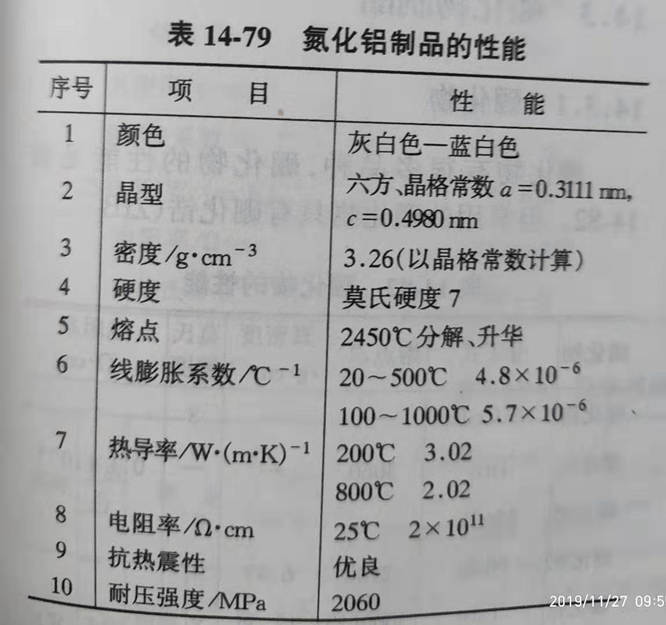

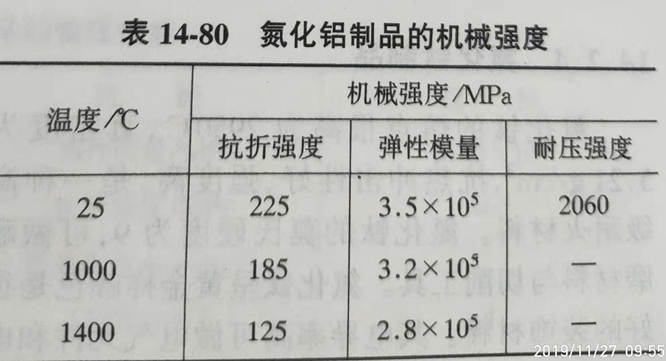

The product was put in a graphite container and put into a carbon tube furnace to pass argon gas. The product was heated for 2h at 1950~2050℃. The properties of aluminum nitride products are shown in table 14-79 and table 14-80.

The chemical properties of the product are as follows:

(1) acid-base erosion resistance: no reaction with dilute acid and concentrated acid, slow reaction with weak alkali, and reaction with strong alkali;

(2) react with wet air at 1200℃;

(3) did not react with carbon monoxide (CO) at 1000℃;

(4) do not react with liquid aluminum, liquid gallium, and liquid boron oxide.

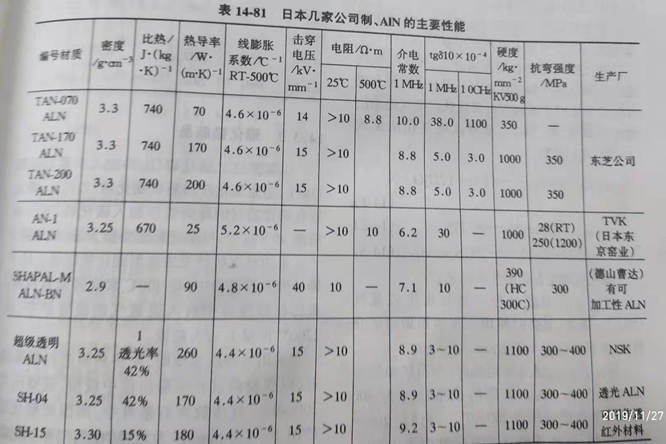

The main properties of aluminum nitride products from Japanese companies are shown in table 14-81.

Application of aluminum nitride products:

(1) crucible for vacuum evaporation and metal smelting;

(2) crucible for synthesizing semiconductor gallium arsenide;

(3) for the invasive thermocouple protection tube, which can be continuously used for 3000h in the aluminum melting pool at 800~1000℃ and 10h in the copper alloy solution at 1300℃;

(4) make refractory materials and lining materials of metal refining furnace;

(5) coating material for alumina products.

Titanium oxide products

Titanium oxide has a high melting point of 2950℃, true density of 5.21g/cm3, good thermal impact resistance, high strength, and is a high and refractory material. Titanium nitride has a mohs hardness of 9 and can be used as wear resistant materials and cutting tools. Titanium oxide in golden color is a good decorative material. Its high conductivity can be used as electrical components and electrodes, also can be used as superconducting materials.

Titanium nitride (TiN) is an important compound in titanium - nitrogen system. Titanium nitride is a group of widely absent solid solution, its stability range is tin1.37-tin1.6. The solid solution with low nitrogen content is the one with absence of nitrogen, and the one with low titanium content is the one with absence of titanium.

Titanium nitride does not react with iron, chromium, calcium, magnesium, molybdenum and tungsten at high temperature. It does not interact with acidic or alkaline slag under atmosphere of CO or N2. Titanium nitride is not soluble in nitric acid, hydrochloric acid or sulfuric acid, but can be soluble in wang shui.

Titanium nitride products have excellent thermal shock resistance, red hot crucible directly into cold water will not crack.

The main synthesis methods of titanium nitride include: ammonia reduction of titanium dioxide and nitriding of titanium powder. High purity titanium nitride can be produced by the above two synthetic methods. The reaction formula of ammonia reduction is shown in equation (14-1), and the nitriding method of titanium powder is shown in equation (14-2) and equation (14-3).

6 tio2 + 8 nh3 - tin + 12 h2o + N2 (14-1)

2 ti + N2-2 tin (14-2)

2 ti + 2 nh3 - > 2 tin + 3 h2 (14-3)

Production process of titanium nitride ceramic products:

Titanium nitride is easy to form ammonia (NH3) with water during wet grinding. Therefore, anhydrous alcohol is used as the grinding medium in wet grinding, and the grinding particle size is less than 2 microns.

When pressing titanium nitride products or crucible, paraffin wax is used as binding agent and the amount of addition is 2%. The forming pressure of the machine press is 300MPa, and the isostatic pressure is 200MPa. The blank body is dewaxed at 200~700℃ and fired at 1500~2000℃ in reducing atmosphere or nitrogen atmosphere.

It is difficult to make low porosity products or crucible when using pure titanium nitride. Proper addition of some titanium oxide can reduce the porosity of products to less than 2%.

Titanium nitride products can also be formed by hot pressing. Molding pressure 20MPa, hot pressure temperature of 1600℃.