Boride and Silicide Products

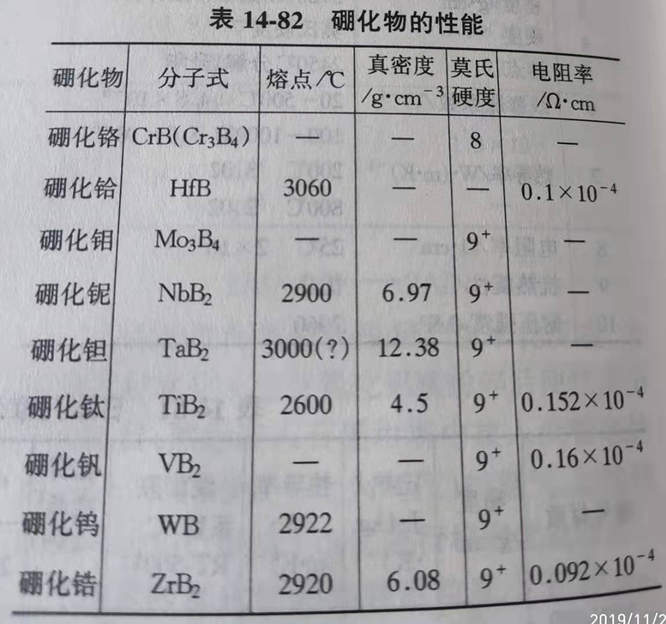

There are many varieties of borides, and the properties of borides are shown in table 14-82. However, zirconium boride (ZrB2) is the only commonly used boride.

Zirconium boride products:

Zirconium boride (ZrB2) was obtained by carbon black (C), boron carbide (B4C) and a small amount of boron trioxide (B2O3). Zirconium boride added tungsten carbide (WC) ball to the ball mill with rubber lining for more than 48h can be made into fine particles with particle size less than 5 m.

Zirconium boride products are formed by mud extruder. After drying, the graphite powder was embedded and the organic matter was removed at 400℃. Finally, it was put into a carbon tube furnace with hydrogen gas in the graphite vessel and burned at 2200℃ for 1~2h.

When isostatic molding is adopted, the powder is firstly spray granulated, and the rubber mold is formed in the isostatic press with a molding pressure of 200MPa. The blank body was placed in the graphite vessel, surrounded by zirconium boride sand (0.5~1.0mm) as filler, and was fired at 2080℃ for 1h in a hydrogen-protected horizontal carbon tube furnace. Properties of zirconium boride products are shown in table 14-83.

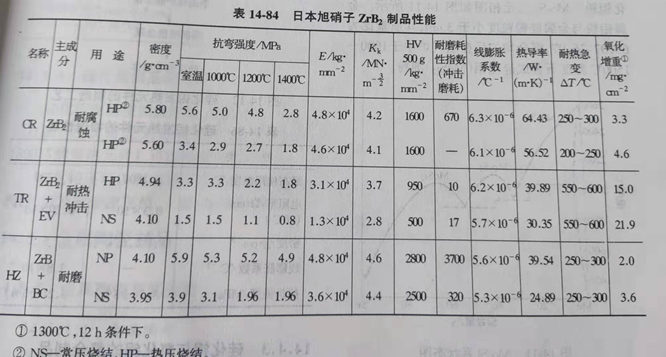

Properties of zirconium boride products produced by asahi company are shown in table 14-84.

Zirconium boride products due to hardness, high conductivity, high thermal conductivity and chemical stability, is a good special refractory.

(1) crucible for smelting many kinds of metals;

(2) smelting various metal casting molds;

(3) protection sleeve of high temperature thermocouple;

(4) the nozzle of the rocket.

Silicide products

Silicide means disilicide. The properties of disilicides are shown in table 14-85.

Molybdenum disilicide (MoSi2) is the most stable substance in the silicide series. The microhardness of 120 mpa, compression strength 2310 mpa, the room temperature resistivity 721 mu Ω cm, 20 ~ 100 ℃ heat conductivity is 3.15 W/(m K). Strong oxidation resistance, the use of 1900℃ in the air atmosphere, resistance to the erosion of molten metal and slag, but with melted alkali.

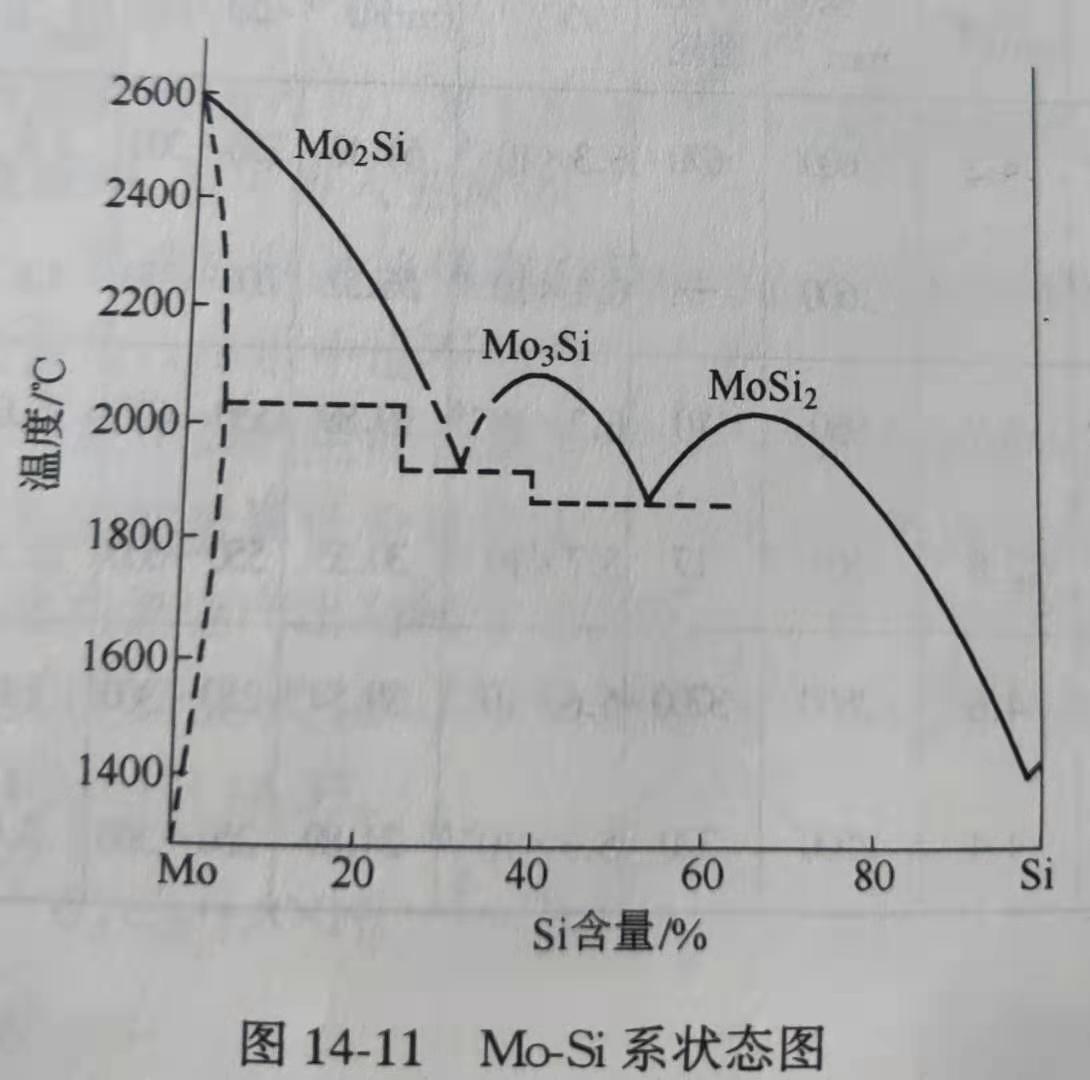

Molybdenum disilicide powder was synthesized by high purity molybdenum powder and silicon powder in hydrogen atmosphere at 1000~1500℃. The mo-si binary phase diagram is shown in figure 14-11. The particle size of molybdenum metal powder and silicon metal powder is less than 3 m, and the mass ratio is 63.07:36.97. After the mixture is well mixed, molybdenum silicide (MoSi2) fine powder is synthesized in a hydrogen furnace at 1000~1500℃.

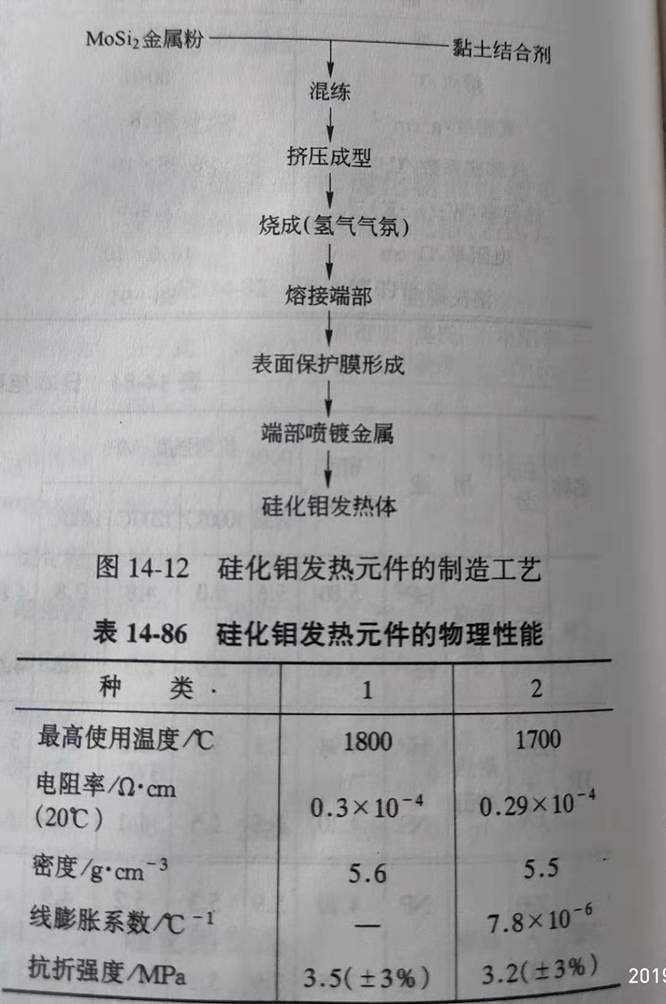

With molybdenum silicide powder as the main raw material, mixed with 2%~4% organic binder and a small amount of clay, formed by vacuum extrusion method, and fired at 1950℃ in hydrogen electric furnace, the heating element with a temperature of 1700~1800℃ can be made. The production process of molybdenum silicide heating element is shown in figure 14-12, and the performance of molybdenum silicide heating element is shown in table 14-86.

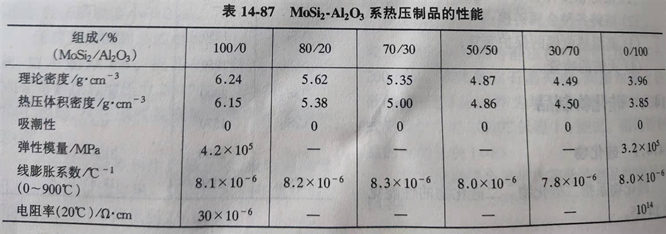

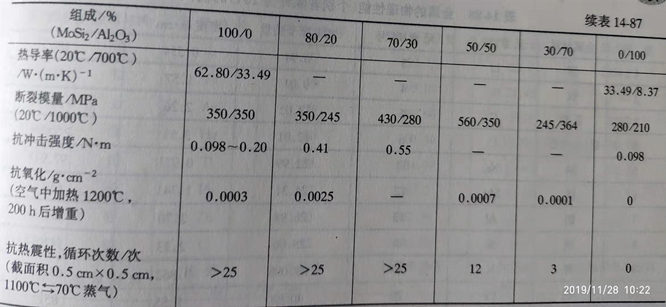

Molybdenum silicide and alumina composite products

The composite products of molybdenum silicide and alumina can be made with different properties as the ratio between molybdenum silicide and alumina changes. Physical properties of molybdenum silicide-alumina series hot-pressed products are shown in table 14-87.

Molybdenum silicide products use high temperature, low resistivity, strong oxidation resistance, can be made without protective atmosphere, use temperature 1800℃ heating element. High temperature thermocouples can be made.

Molybdenum silicide can also be made into heat exchangers for atomic reactor devices and parts for supersonic aircraft, rockets and missiles.