Production Technology of Metal Ceramic Products

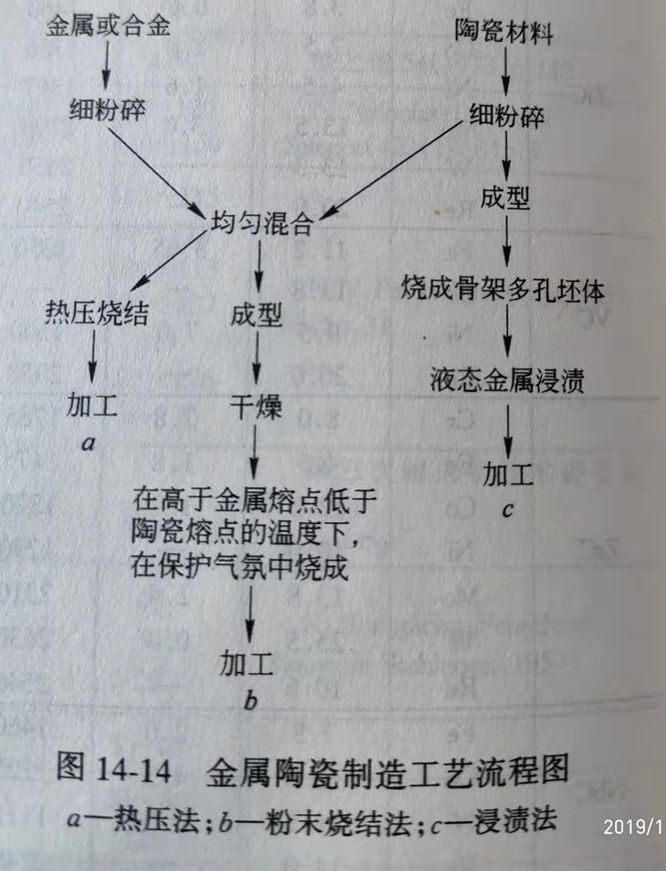

The production process of cermet products is basically the same as that of special refractory products and powder metallurgy products. The most important thing is the preparation of ceramic powder and metal powder. Oxide ceramic fine powder should use advanced fine powder processing equipment and advanced processing technology, and the particle size of the fine powder should be less than 1 μm (such as stirring mill, vibration mill or ball mill with the same medium, etc.). The metal powder can only be processed into fine powder in the same cermet or metal grinding equipment, and organic liquids must be added as grinding media (alcohol, acetone, etc.) for wet grinding. The fine powder must be evenly distributed during mixing After mixing, it should be dried in a low-temperature and vacuum drying box to prevent metal oxidation.

Molding and firing: The product is molded by pressing, grouting, extrusion or isostatic pressing, and then fired in a high temperature furnace with a protective atmosphere (hydrogen or neutral atmosphere). Products with simple shapes can also be formed by hot pressing.

The firing temperature range of cermets is generally higher than the melting point of the metal and lower than the sintering temperature of the ceramic. The sintering mechanism has the following two cases:

(1) Sintering without reaction between solid phase and liquid phase, generally sintering of cermets based on oxide-metal.

(2) Sintering to which a certain degree of reaction occurs between the solid phase and the liquid phase, is generally a sintering of a cermet based on a carbide-metal.

The production process of cermet products is shown in Figure 14-14.

Performance and application of cermet products

1) Varieties and applications of oxide-based cermets

The oxide-based cermet has the characteristics of high performance, good use effect, and wide application range. The applied varieties are:

(1) Al2O3-Cr, Al2O3-W-Cr cermets can be made into missile nozzles, nozzle gaskets, and flame stabilizers.

(2) Al2O3-Cr, Al2O3-Mo, MgO-Mo, ZrB2-Mo, and ZrO2-Mo cermets can be made into control rods for adjusting metal flow in metallurgical production, pouring grooves, and measurement of various metal melts. Warm thermocouple protection sleeve.

(3) ZrO2-Ti, ZrO2-Zr cermets can be made into crucibles for smelting certain metals.

(4) Al2O3-MgO-Fe, Al2O3-Mo (Fe, Co, Ni, Cr) cermets can be made into various cutting tools.

(5) Al2O3-Fe, Al2o3-TiO2-Cr-Mo cermets can be made into high-temperature mechanical seal rings.

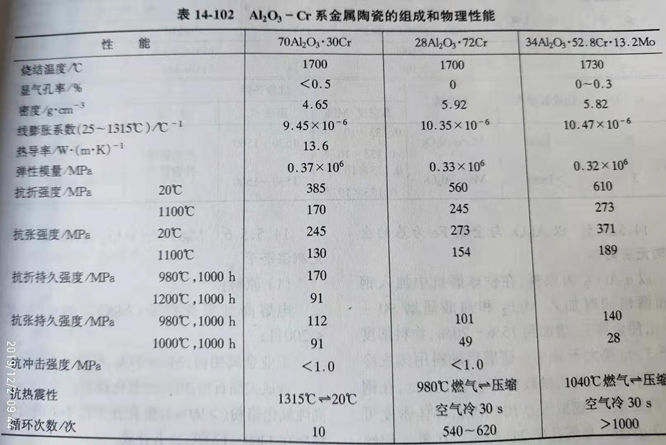

2) Performance of cermets based on alumina and metal Cr

Its performance is shown in Table 14-102.

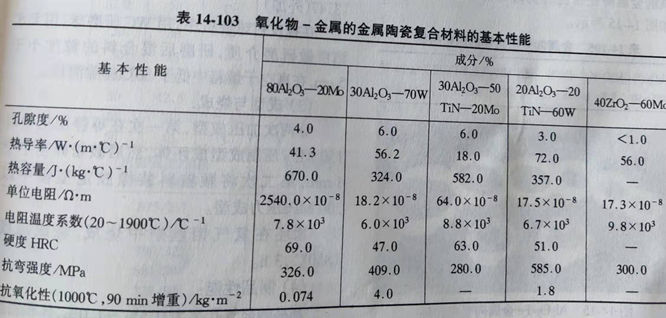

Properties of cermets based on alumina and metals W, Mo, etc.

Its performance is shown in Table 14-103.

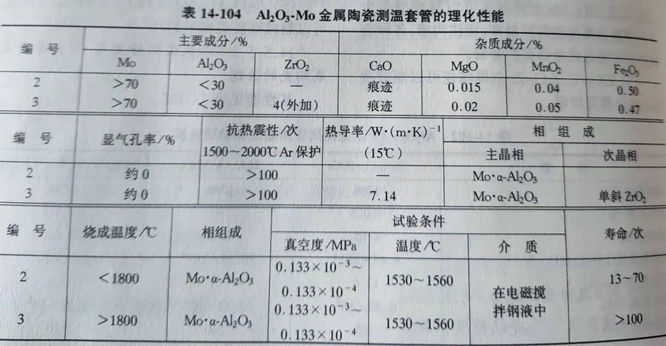

Physical and chemical properties of cermet temperature measuring sleeve made of alumina and metal Mo

Its performance is shown in Table 14-104.

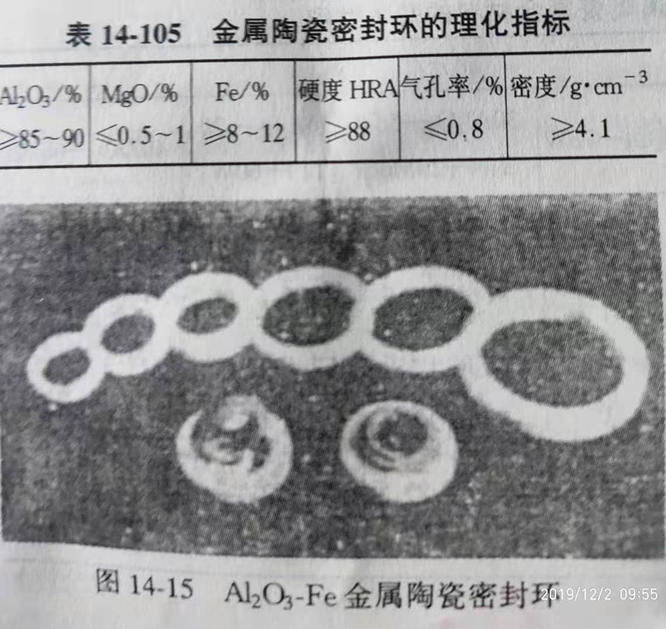

3) Cermet seal ring based on Al2O3 and metal Fe

With α-Al2O3 as raw material, steel balls and alcohol are added to the iron ball mill, while MgF2 and oleic acid are added for grinding for 90 ~ 100h, the metal Fe is increased to 15% ~ 20%, and the material fineness is less than 3μm and greater than 96%. The milled material was recovered with an evaporative condenser, and the agglomerates were crushed and crushed to less than 100 mesh. They were machine-formed in a steel mold with a molding pressure of 100 MPa, a green body density of 2.7 g / cm3, and a significant porosity of 21.32%. It was fired in a hydrogen aluminum wire furnace at 1700 ° C for 1.5 hours. The physical and chemical properties of the alumina-metal iron cermet seal ring are shown in Table 14-105, as shown in Figure 14-15.

4) MgO-MgO · Cr2O3-Mo cermet temperature measuring sleeve

(1) Raw materials:

Fused high purity magnesium oxide powder: MgOg99%, particle size ﹤ 200 mesh;

Industrial metal molybdenum powder: Mo ﹥ 99%, particle size ﹤ 200 mesh;

Synthetic spinel powder: high purity magnesium oxide powder (﹥ 99.5%), high purity chromium oxide powder (﹥ 99%), mixed at 1400 ~ 1700 ℃, and synthesized in 1: 1 at a molar ratio of 1: 1.

(2) Ingredients:

Ingredient ratio: MgO: Mo: MgO · Cr2O3 = 34.7: 65.3: 3.47 (plus)

In a rubber-lined ball mill, WC grinding balls are used, and anhydrous alcohol is used as a grinding medium. After the grinding, the particle size of the mixture is less than 5 μm, and the alcohol is excluded in a vacuum drying box below 80 ° C.

(3) Forming and firing

It is press-molded in two steps. The first time it is pressed into a green body at 150 MPa in an isostatic press, and then crushed to less than 1 nm, and the second time it is shaped into a rubber molding mold at 200 MPa.

The green body was fired in a hydrogen molybdenum wire furnace at a firing temperature of 1850 ° C for 3 hours.

(4) Product performance:

The apparent porosity of the product is 0.5% ~ 1.0%, the bulk density is 5.8 ~ 6.28g / cm3, the linear shrinkage is 15% ~ 16%, the MgO content is greater than 30%, and the metal molybdenum content is greater than 65%.

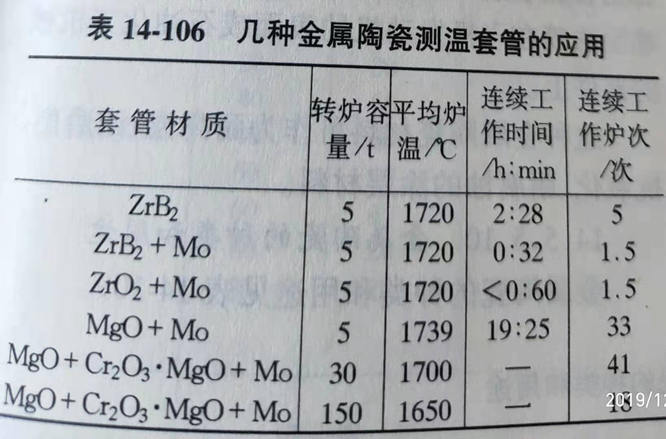

A comparison of the use of several cermet temperature measuring sleeves is shown in Table 14-106.

5) Cermet based on zirconia and metallic cobalt

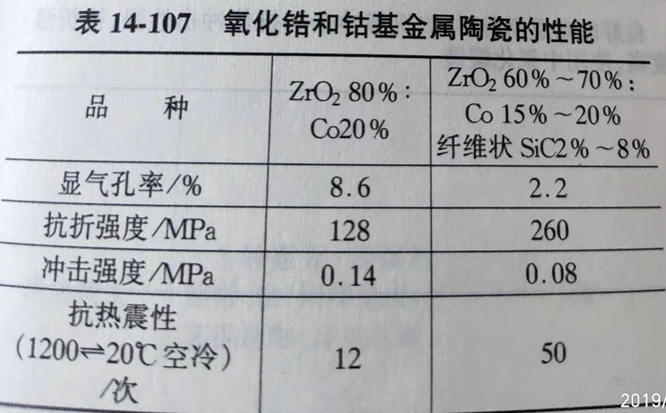

This cermet is made at a temperature of 1550 ° C and a pressure of 15-20 MPa under hot pressing conditions. The properties of its products are shown in Table 14-107.

6) Ceramics made by infiltration

This process method is to infiltrate the molten metal liquid into the porous alumina precursor, the premise is that the metal liquid must have good wettability to the alumina precursor. There are two production and processing methods: the first is to apply a metal coating on the alumina matrix, and the metal can penetrate into the pores inside the matrix after heating, and the second is to allow the molten metal to penetrate directly to form a reducing layer inside the matrix. . The performance of the cermet thus produced is good. The molten metals used in the test are: copper and copper alloys, aluminum and aluminum alloys, nickel, iron-titanium alloys, zirconium alloys, and the like.

7) Carbide-based cermet

A TiC-Ni-Mo cermet

Synthesis of TiC: TiO2 and carbon black (C) are mixed uniformly, and the amount of carbon powder added should be greater than the calculated amount. After molding, carbonization treatment at a temperature of 1800 ~ 2000 ° C under vacuum conditions can be used to make high-quality TiC. The reaction formula is as follows:

TiO2 + 3C → TiC + 2CO

In TiC powder, the combined carbon content should be between 18.0% and 20.03%, and the free carbon content should be between 0.1% and 0.8%. It has a metallic luster and is light gray.

In order to improve the oxidation resistance of TiC cermets, a solid solution of TiC-Cr3C2 or TiC-TaC-NbC can be added to the ingredients, and metal Ni with good oxidation resistance can be used as a binder. Increasing the metal content can improve the toughness of cermets.

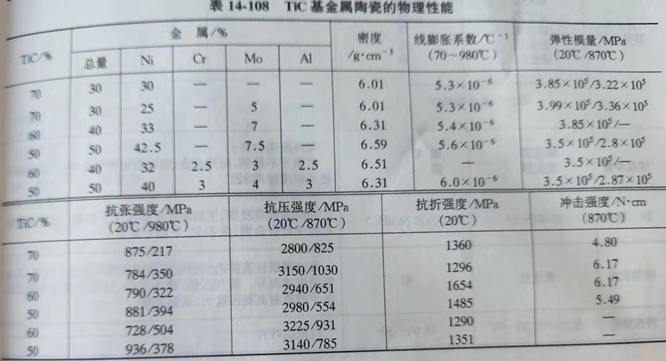

The physical properties of TiC cermet are shown in Table 14-108.

B Cr3C2-Ni-Cr cermet

Synthesis of Cr3C2: Cr2O3 and carbon black (C) are synthesized under the protection of an inert gas or a reducing gas. The reaction formula is as follows:

3Cr2O3 + 11C → 2Cr3C2 + 9CO

The synthesized Cr3C2 and Ni-Cr alloy powders were finely ground by adding a WC ball in a stainless steel ball mill with a mass ratio of 3: 1 and 40% alcohol, and the ball-to-ball ratio was 4: 1. After grinding for 48 hours and drying, it passed through a 35 mesh sieve. Add 9% of polyvinyl alcohol as a binding agent to this mixed powder, use a press to make a 0.5mm thick sheet, dry it naturally and crush it into small particles. Put it into a graphite boat and pass argon in a carbon tube furnace. Protected at 1280 ° C. After cooling, it is made into a fine powder in a vibration mill, and when used, it is sprayed on the surface of an aircraft engine or a component of a petrochemical machinery by plasma spraying.

This cermet material can be used as a coating material with high temperature resistance, wear resistance, oxidation resistance and corrosion resistance.

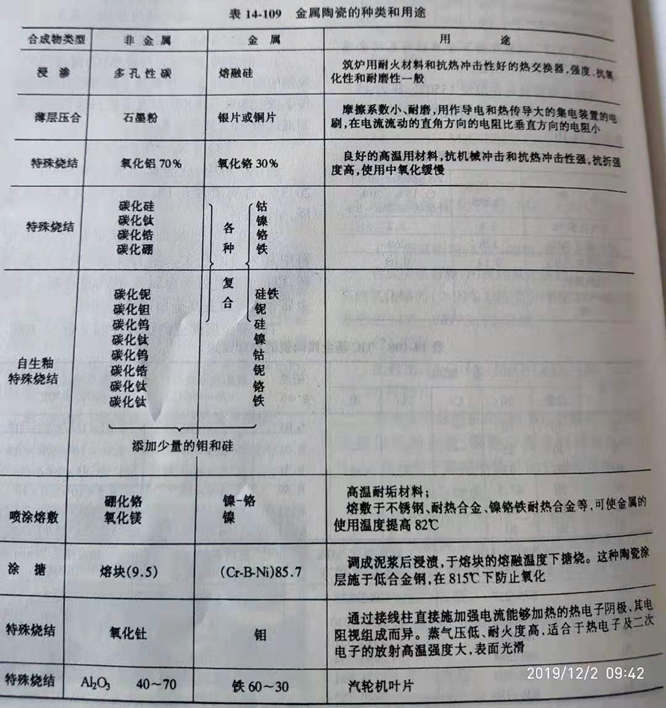

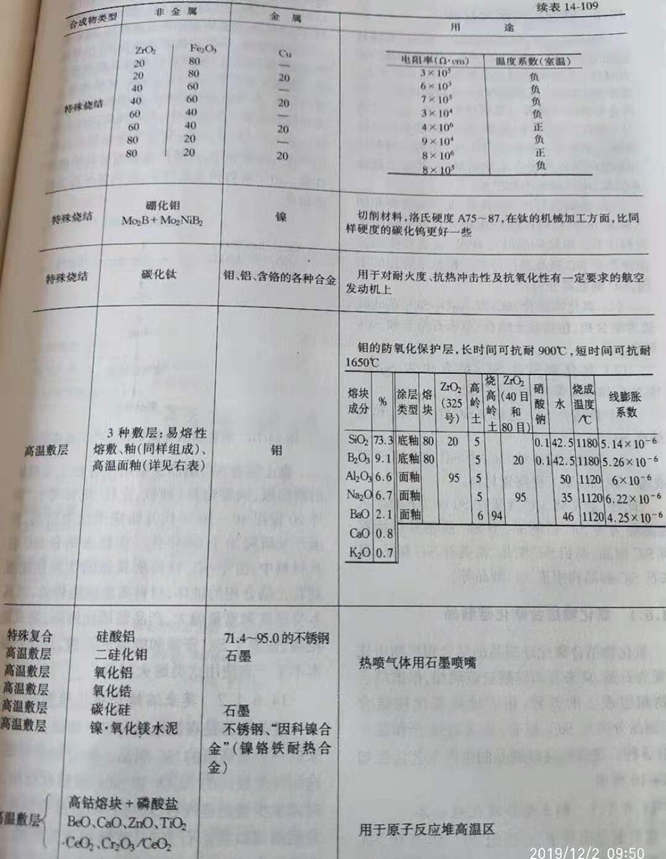

The types and uses of cermets are shown in Table 14-109.