Self-bonded SiC

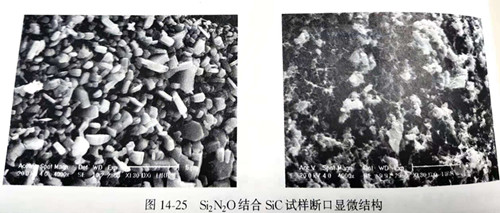

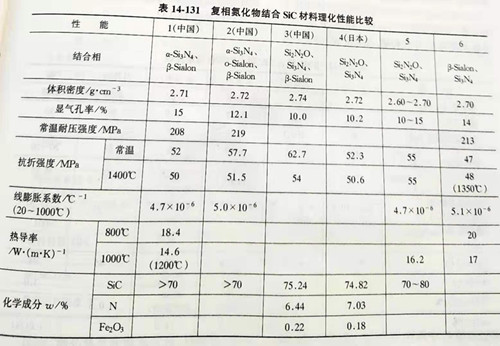

Using the current reaction sintering process, it is generally difficult to produce pure silicon nitride (Si2N2O) bonded SiC products, Si2N2O bonded SiC products usually refers to Si2N2O/Si3N4 complex phase nitride bonded SiC materials with Si2N2O as the main binding phase. Compared with Si3N4 combined with SiC, the apparent porosity of the material is lower, and the oxidation resistance and thermal shock resistance of the material are better. In the microstructure, the binding phase Si2N2O is mainly granular crystals, with a small amount of lamellar or striated crystals. Si3N4 is mainly granular and columnar crystals, with fewer acicular or fibrous crystals, as shown in figure 14-25. These irregular networks of Si2N2O and Si3N4 bind SiC particles tightly.

Si2N2O adheres to SiO2 film on the surface of SiC and reacts with it to form a continuous protective film, which is favorable for the long-term oxidation resistance of the material.

In addition to conventional nitrogen kiln, Si2N2O bonded SiC products can also be prepared by burning in air under the condition of carbon burial. Under the condition of high temperature carbon burial, in addition to 3Si+2N2→Si3N4 reaction, 6Si+2CO+2N2→2Si2N2O+2 su-sic reaction, 6Si+2CO+2N2→2Si2N2O+ 2Si2N2O+2 su-sic reaction can also occur. The choice of sintering process is more flexible than that of Si3N4 combined with SiC, and the production cost of the two sintering methods is not significantly different. Si2N2O combined with SiC has been used as blast furnace lining in the past, accounting for about 1.2% of the total SiC bricks. At present, Si2N2O combined with SiC products is no longer used as blast furnace lining in the world. At present, it is widely used in metallurgical furnace, chemical equipment and power generation boiler lining, as kiln has gradually shown its superiority.

Si3N4/Si2N2O, Si3N4/Si2N2O, Si3N4/Sialon, Si3N4/Si2N2O/Sialon, Si3N4/ Si3N4/Sialon, Si3N4/Sialon, Sialon/Si3N4 /Sialon, Sialon/Si3N4 /Sialon, Sialon/Si3N4 /Sialon, Sialon/Si3N4 /Sialon, Sialon/Si3N4 /Sialon, Sialon/Si3N4 /Sialon, Sialon/Si3N4 /Sialon, Sialon/Si3N4 /Sialon, Sialon/Si3N4 In recent years, there are basically no domestic manufacturers to produce and supply Sialon/Si3N4 combined SiC bricks for blast furnace. It is speculated that Sialon/Si3N4 SiC products used in blast furnaces will be gradually replaced by Si3N4 and Sialon SiC.

Si2N2O combined with SiC, Si3N4/Si2N2O, Si3N4/Sialon, Si3N4/Si2N2O/Sialon complex phase nitride combined with SiC kiln furniture products have been successfully applied. The application in ceramic, electric porcelain, grinding wheel and other industries shows that Si2N2O binding and complex phase nitride bonded SiC kiln tools have better stability and service life than Si3N4 bonded SiC materials, which may become the main material of nitride bonded SiC kiln tools in the future.

Self - bonded silicon carbide products can be divided into SiC -SiC bonded SiC and recrystallized SiC.

-sic combined with SiC products

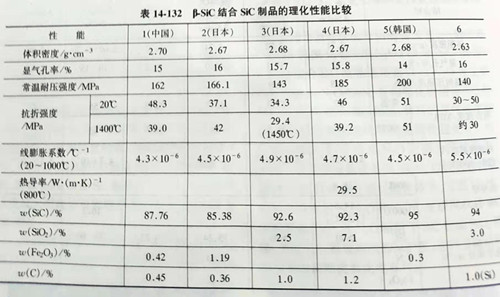

In industrial ɑ - SiC materials, Si powder and C powder, adding binder, after mixing, molding and drying under neutral or reducing atmosphere (usually buried carbon process) in 1400 ~ 1600 ℃ firing, using high temperature reaction Si + C - beta SiC generated by the low temperature type beta SiC the original high temperature type ɑ - made by SiC particles together. In addition to Si+C→ ni-sic, 3Si+N2→Si3N4, Si3N4+SiO2→2Si2N2O, 6Si+2N2+2CO→2Si2N2O+2 ni-sic and other reactions will occur in the process of buried carbon combustion. Beta SiC combination of SiC materials phase is given priority to with beta SiC, usually there is a small amount of Si2N2O, Si3N4 and a small amount is not completely free Si and C reaction, products in ɑ - SiC particles was wrapped by microcrystalline beta SiC. The production process of nh-sic combined with SiC is more complicated, and the production cost is slightly higher than that of Si3N4 combined with SiC products. However, the weight and size of nh-sic combined with SiC products are not limited by the manufacturing process, and large products weighing up to 270kg can be prepared, while nitride combined with SiC is difficult to prepare thick products restricted by nitride sintering process conditions.

Due to the fine grain size and high activity of the combined su-sic, its oxidation resistance, water vapor resistance and mechanical strength are generally not as good as Si3N4 bonded SiC products, but its high-temperature strength, creep resistance, alkali resistance and oxidation resistance are close to Si3N4 bonded SiC products.

SiC -SiC combined brick can be used as blast furnace lining brick and tuyere combination brick, garbage incinerator lining, etc. In foreign countries, in the late 1970s and early 1980s, SiC bricks used in blast furnaces were mainly SiC -sic combined with SiC products. After 1980s, except in Japan, the use of blast furnace SiC combined with SiC gradually decreased, while Si3N4, Sialon and Sialon/Si3N4 combined with SiC increased year by year. In the 1990s, luoyang refractories research institute and baosteel co., ltd. successfully developed the combination brick with the combination of si-sic and si-tuyat. The physical and chemical indexes of the product reached the Japanese product indexes, which could replace imported materials. At present, some of China's large blast furnace tuyere combination bricks still use the combination of SiC and SiC bricks, are Japanese products, China's research and production in this product needs to be strengthened. Physical and chemical indexes of SiC -SiC combined with SiC products at home and abroad are shown in table 14-132.

Recrystallization SiC products (R - SiC) is a kind of no other combination of SiC products, it is a kind of formed by SiC grain recrystallization grain size and grain directly connected to ɑ - SiC single-phase ceramic material. SiC has atomic covalent bonds, small molar volume, large lattice energy, does not melt at high temperature, and evaporates at 2273℃, with great vapor pressure. Sintering of SiC is accomplished by means of evaporation-condensation mass transfer, and its strength is enhanced by gas-phase sintering.

When r-sic products are fired, they do not shrink, but their mass decreases, which is more obvious over 2000℃ and more intense over 2200℃. With the decrease of mass, the porosity of products increases correspondingly. At 2150~2200℃, SiC has the maximum strength through recrystallization. If the recrystallization temperature is further increased, the vapor pressure of SiC will significantly increase, leading to excessive increase of porosity and reduction of strength.

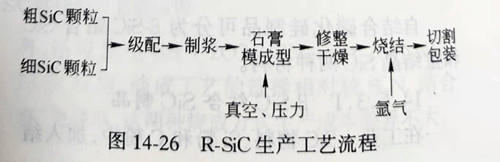

Initially, r-sic products were manufactured by hot pressing using recrystallization of SiC, but hot pressing is not suitable for large refractory products. R-sic blank body can be pressed, ramming, extrusion, isostatic pressure and pouring (or grouting) and other forming methods. At present, r-sic products mainly adopt grouting molding, and its technological process is shown in figure 14-26.

When R-SiC products are prepared by grouting, the maximum particle size of SiC raw materials is generally only 0.2~0.3mm, requiring w(SiC) of 10, 99 percent. The particles are nearly spherical, requiring higher raw materials than other SiC products. At present, imported raw materials are mainly used for R-SiC production in China, and the cost of raw materials is relatively high.

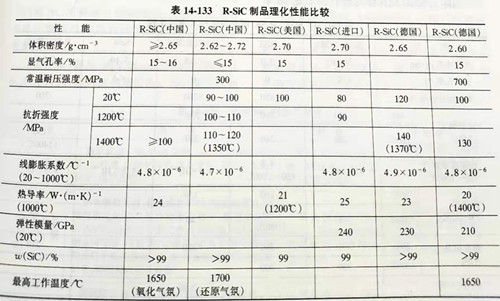

In the 1970s, a few foreign countries successfully developed r-sic products. In the 1980s, they entered China and were mainly used in the kiln industry. Although the research on r-sic kiln ware in China is early, the production scale has not been formed yet, and only small batch samples can be provided, which has a big gap with foreign products in performance. In the mid-1990s, tangshan fossett fine technology ceramics co., ltd. and shenyang xingguang technology ceramics co., ltd. successively cooperated with Germany FCT company to introduce relevant production technology and key equipment, which greatly narrowed the gap between China's technology and production level. At present, China's production of r-sic has reached the international advanced level of similar products in the 1990s, and there are products exported. The technical performance indexes of r-sic products at home and abroad are shown in table 14-133.

R-sic products with high temperature strength, light weight, no slag, good heat conduction, small heat storage, long life and other excellent performance, has been widely used in ceramic, petrochemical, aerospace and other industrial sectors, for the production of ceramic roller, beam, ceiling, high temperature burner, thermocouple protection tube. Among them, the most typical use is as high temperature kiln tools for various industrial kilns, especially suitable for use under high temperature conditions above 1250℃. The use of r-sic kiln tools can significantly improve the loading efficiency and save energy consumption.

For R-SiC products, the raw material cost is high, the production equipment requirements are high, the production technology is difficult, the product price is generally Si3N4 combined SiC products 10~20 times. It is used in much smaller quantities than oxides and nitrides combined with SiC products.