SiC Products and Applications

Penetration of silicon carbide products (SiSiC) is a kind of excellent performance of SiC/Si duplex ceramic material, material Si in the formation of a continuous phase or Si and SiC as continuous phase, mainly USES the reaction sintering process, so this kind of material is often referred to as osmotic reaction sintering SiC. Reaction sintering SiC is Popper, invented in the 1950 s, whose basic principle is: with reactive liquid Si or Si alloy, under the action of capillary force, infiltration of porous ceramics containing C billet, and instead of C reaction of SiC, newborn SiC in situ combined slab SiC particles in the lithosphere, The remaining pores in the billet filled with impregnating agent complete the densification process. The production process is SiC powder, C powder and binder → mixing → forming → drying → atmosphere protection and coke exhaust → high temperature infiltration Si (vacuum sintering) → mechanical processing. At present, most domestic and foreign SiSiC products are prepared by this process. Reaction sintering SiC process has the following advantages: simple process, low sintering temperature, short time, net size sintering, easy to prepare large complex shape products, production cost is far lower than hot press and no pressure sintering SiC.

SiSiC inherits almost all the advantages of SiC ceramics, including high strength, high hardness, good thermal shock resistance, good wear resistance and corrosion resistance, high thermal conductivity, low linear expansion coefficient, excellent antioxidant properties and low apparent porosity (about 0.5%). SiSiC can be used as ceramic roller, burner, thermocouple protection tube, sandblasting nozzle, desulfurization nozzle of large boiler, seal and kiln tool (beam, shed board, sagger), etc.

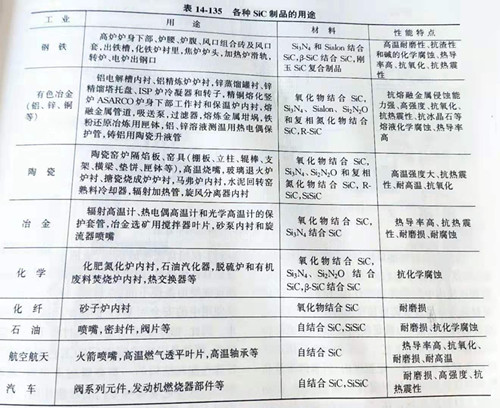

Internationally, SiSiC began to be used as kiln furniture in the early 1990s. In China, similar products were produced in 1994, but their performance was far worse than that of imported products. In 1996, weifang huamei fine technology ceramics co., ltd. cooperated with Germany FCT company to introduce the production line into full production. Since then, China's SiSiC products have been basically in line with the international standards in terms of technical performance and production technology. At present, the quality of China's SiSiC products has reached the world's advanced level, and the products have been exported to Germany, Italy, South Korea and other countries in batches. Table 14-134 compares the technical indexes of SiSiC products at home and abroad, and compares them with r-sic.

The most typical use of SiSiC products is as thin wall middle beam and ceramic roller for industrial kilns under 1350℃. Compared with r-sic kiln products, it has the following characteristics: obvious porosity is very low, with a strong antioxidant capacity; The bending strength at high temperature is twice that of r-sic, and the bearing capacity is larger. Better thermal conductivity; Good volume stability in limit temperature range. The service life of SiSiC kiln tools is 2~3 times that of r-sic under 1350℃. SiSiC products are expensive. In the past, they were usually 1.2 to 1.3 times more expensive than r-sic. At present, the price of domestic SiSiC products has been greatly reduced, and the price of most products is lower than r-sic. Compared with the common use of oxide and nitride combined with SiC products, its dosage is much less.

Semi-sic products are SiC refractory products containing SiC as a secondary or auxiliary component. At present, each country does not have this kind of product unified specification, name. According to its material, it can be divided into clay clinker SiC products, high aluminum SiC products, mullite SiC products, zircon SiC products. Because such products contain less than 50% SiC, their thermal shock resistance, thermal conductivity and strength are significantly improved. At present, clay clinker SiC products, high aluminum SiC products and corundum SiC products are widely used in industry.

Clay clinker SiC products: referred to as clinker SiC products, which are made from refractory clay and clay clinker with the addition of SiC. Adding a small amount of SiC to clay clinker can improve the thermal shock resistance of products. With the increase of SiC fine powder content in the ingredients, the thermal shock resistance of the products increases gradually.

High aluminum SiC products: alumina as the main body of both high thermal shock resistance, high strength, high fire resistance and high thermal conductivity refractory. High aluminum SiC products have high strength at room temperature and high temperature. The dependence between the properties of the products and the SiC content is the same as that of the above mentioned clinker SiC products. The final firing temperature was 1370~1380℃ and the heat preservation was 6~8h. High strength fired products of high aluminum SiC containing phosphoric acid can also be prepared, which have high thermal shock resistance, good thermal conductivity and high strength.

SiC products of corundum: corundum products have high strength, good wear resistance and strong slag resistance, but low thermal shock resistance. In order to improve its thermal shock resistance, adding a small amount of SiC powder has a significant effect, and the thermal shock resistance increases regularly with the increase of SiC powder content. Using brown corundum as aggregate, adding 10%SiC fine powder and phosphoric acid as binder, the slide-rail brick for steel rolling reheating furnace is formed by high pressure molding and fired at 1450℃.

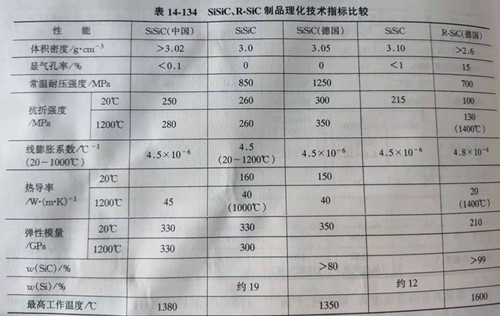

SiC products belongs to high-grade refractory materials with high mechanical strength, high thermal conductivity, good thermal shock resistance and abrasion resistance, good resistance to alkali erosion resistance, good slag resistance and oxidation resistance, as well as to the partial melting metal resistance ability and so on characteristics, has been widely used in steel, non-ferrous metallurgy, petroleum, chemical, electricity, ceramics and industrial fields such as aerospace, and increasingly shows other refractory has the incomparable advantages. Table 14-135 summarizes the USES of SiC products.