Continuous Steel Casting and Functional Refractories

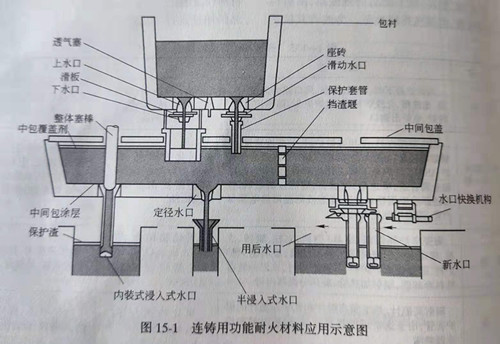

Functional refractory is a kind of special refractory formed with the development of continuous casting technology in iron and steel metallurgy industry. Rather, it should be called metallurgical functional refractory. At present, the main refractory products include: sliding nozzle, integral plug rod, immersed nozzle (commonly known as continuous casting three), breathable plug and sizing nozzle. Their use in the continuous casting process is shown in figure 15-1. Each product has a special function in use, such as controlling the flow, stirring the air, preventing secondary oxidation and protecting the casting, and determining the flow field distribution of molten steel in the mold. The use of these refractory materials is one of the important prerequisites to ensure the continuous casting process.

Functional refractory be filed as a kind of refractory alone, not just because they are more application in the form of unit element and in the use of special function role, but also is this kind of material to meet more often harsh conditions of use should have special performance, to meet the use function of special structure and special manufacturing process. Compared with other lining refractories for steel smelting, the quality of the latter may only affect the service time of the lining to a certain extent, while the quality of functional refractories may affect the process of continuous casting. This requires that functional refractories not only have the same basic properties as conventional contact molten steel and slag refractories, such as resistance to high temperature, slag and molten steel erosion, but also have special or special requirements on the safety and reliability of the structure, material, production technology and use, depending on the different conditions of use. Therefore, if we want to give a definition of functional refractories, it is a special or special process prepared with special properties and structure of a class of advanced refractories, in the process of high temperature use plays a special functional role. In a sense, they can be called fire-resistant functional elements.

Functional refractory materials compared with conventional refractory products, its characteristic is: in the use of metallurgical process of special functional role, often as a single element or with some auxiliary refractory products combination, on the creation of a special production process, material choice and high-grade refractory materials are almost has a high performance, such as magnesium carbon materials, aluminum zirconium materials, carbon materials, just the quality of the jade, zircon oxide, etc., is the cause of most of currently used functional refractory refractory material containing carbon. The use of functional refractories are more demanding conditions, such as the slide plate in use to withstand the thermal shock of high temperature molten steel and the sliding surface when flow control wear; The long nozzle, integral plug rod and immersed nozzle for continuous casting are subjected to thermal shock of molten steel and strong erosion of slag during pouring. The plug is subjected to the strong thermal cycling during operation and the erosion of the liquid steel flow under the turbulence of air flow, etc. With the continuous development and maturity of continuous casting technology, the service life and function of functional refractories are more and more demanding. Therefore, the common requirements for functional refractories are as follows: in order to ensure the safety and reliability and high service life under harsh operating conditions, functional refractories should have high thermal shock resistance, anti-spalling resistance, high anti-erosion resistance, as well as the corresponding structural characteristics to play its functional role.

Functional refractory is a new family of refractory, variety, material, performance, structure, use technology are in the development. With the development and technical progress of metallurgical technology and other high temperature new technology, some new and special functional requirements for refractory materials will be put forward. The variety of functional refractories will increase, and new functional refractories will also appear, such as thin strip continuous casting molten steel distributor and side seals, mid-pack air permeable elements, various forms of filters, etc. At the same time, the trend of the functionalization of refractory materials is also increasing, the concept of "function" is also expanding, and is called an important direction of the development of refractory materials: for the smelting of clean steel, clean steel, it is necessary to research and develop refractory materials with purification function of molten steel; In order to reduce the temperature drop of steel and reduce energy consumption, it is necessary to research and develop ladle refractory with heat insulation function. In the narrow sense, the material, manufacturing process, performance index and application of functional refractories for continuous casting are introduced, including sliding nozzle, breathable brick, long nozzle, immersed nozzle, integral plug rod and sizing nozzle.

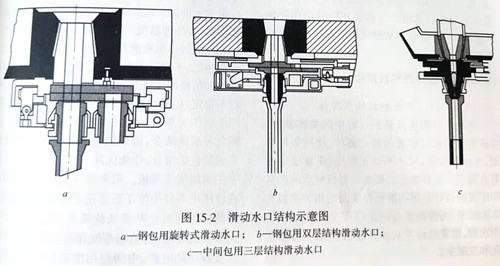

The sliding nozzle structure, as shown in figure 15-2, is a set of devices installed at the bottom of a ladle (or tundish) to control the flow of molten steel, including the upper and lower nozzle tiles and the upper and lower slide boards, the key components of which are skateboards. Sliding nozzle replaces the traditional sleeve brick and plug brick, and the combined flow control system of shuikou brick makes the operation of pouring steel process simple, safe, reliable, accurate flow control, ladle turnover is accelerated, and the consumption of refractory material is reduced.

As early as 1884, d. lewis of the United States proposed the idea of sliding nozzle device to control the outflow of molten steel in ladles and applied for a patent, but it was not until 1964 that the German bentler steel company made the first practical application and achieved success. The obvious advantages of this technology in flow control, operation, safety, convenience and other aspects make it get the attention of the whole metallurgical industry and get the rapid promotion, and soon be widely used in the world. It has become an important flow control system in pouring process and an indispensable technology for the secondary refining of molten steel in ladles and tundish. Since the use of the 1960s, the technology has been improving, improving and perfecting its functions. Sliding shuikou in China since the promotion in the 1980s, the rapid development, has been widely used.

As a device to control the flow of molten steel, the sliding nozzle structure is reciprocating and rotating, and can also be divided into two or three layers of slide plate with holes. Generally ladle with a two-layer structure of sliding plate, the upper plate is fixed under the ladle nozzle, and the lower plate and nozzle are fixed in a linear reciprocating movement of metal sliding box. When in use, make the casting mouth of the upper and lower slide stagger, fill the hole of the upper nozzle with quicksand, ladle can be loaded into the molten steel, when driving the lower nozzle to connect the upper and lower casting mouth, steel can be poured. The upper slide is fixed with the upper slide, the lower slide is fixed with the lower slide and the immersion nozzle, and the middle slide is movable to regulate the flow of molten steel into the mold. In the production, it is divided into composite skateboard and homogeneous skateboard, the former sliding surface and casting parts main raw materials with high-grade raw materials, such as fused corundum, other parts with low-grade raw materials, such as bauxite clinker, in order to reduce the cost. FIG. 15-2 shows a schematic diagram of reciprocating sliding nozzle for ladle and ladle and rotating sliding nozzle for ladle.