Production Technology of Aluminum Carbon Slide Board

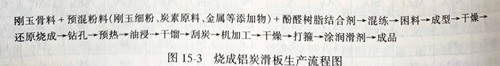

The preparation process of skateboards varies with different materials. Aluminum carbon skateboard with outstanding thermal shock resistance, corrosion resistance, has been the main body of the skateboard for many years, but also the leading products of skateboard manufacturers. Aluminum carbon skateboard through a special skateboard production line, the product is divided into two types of non-fired and fired, mainly fired into skateboard, in addition to burning the two in the production process is the same. Aluminum carbon slide mainly consists of sintered alumina and 3%~12% carbon raw materials, phenolic resin binder, reduction atmosphere fired. In order to improve the quality, most skateboards impregnate asphalt to increase the density, strength, reduce the porosity. With the introduction of zirconium mullite, zirconium corundum, metal, carbide and other raw materials, the selection of graphite, material thermal shock stability (anti-peeling), anti-erosion, anti-oxidation, thermal strength and other properties have been optimized, skateboard service life gradually increased. At present, large and medium-sized steel mills in China are basically used to burn aluminum carbon skateboard or aluminum zirconium carbon skateboard. The production process of aluminum carbon slide includes blank mixing, high pressure forming, protective firing, oil immersion, processing, hoop and other processes. The simple production process is shown in figure 15-3.

(1) raw materials. The main raw materials of aluminum carbonized skateboards are corundum, bauxite and carbon raw materials. The main auxiliary raw materials are zirconium corundum or zirconium mullite, metal powder and non-oxide to improve and optimize the thermal shock resistance, corrosion resistance, oxidation resistance and other performance of skateboards. The performance of the skateboard is determined by the type and ratio of raw materials, the choice of binders and additives, the manufacturing process and parameters, and the structure of the skateboard.

1) corundum raw material, the performance of the slide is related to the content of Al2O3. The content of Al2O3 is high and the corrosion resistance is good. When it is low, the thermal shock resistance is good. Therefore, corundum raw material is the main raw material of aluminum carbonaceous skateboard. The selection of corundum raw material requires high taste and low impurity content.

2) zirconium mullite (ZM) or zirconium corundum (ZA), is the main material introduced in the production of high-grade aluminum zirconium carbon skateboards, ZA or ZM has lower thermal expansion rate and higher corrosion resistance than corundum, its role is to improve the erosion resistance and thermal shock resistance of skateboards, in order to further improve the service life of skateboards.

3) carbon raw material, carbon has good high temperature performance, plays a role in the aluminum carbon slide to improve the corrosion resistance and thermal shock resistance and a certain role in high temperature lubrication, corrosion resistance and thermal shock resistance to increase proportional to the amount of graphite. The main properties of non - fired or fired aluminum carbon slide boards are improved by the addition of graphite, and the service life is higher than that of high aluminum slide boards. Carbon components can be introduced by natural flake graphite, tar, coke or carbon black, natural flake graphite antioxidant, carbon black and other high activity, easy to react with aluminum, silicon and other additives to fill pores to improve the performance, so the use of two carbon better, the general carbon content of 8%~15%.

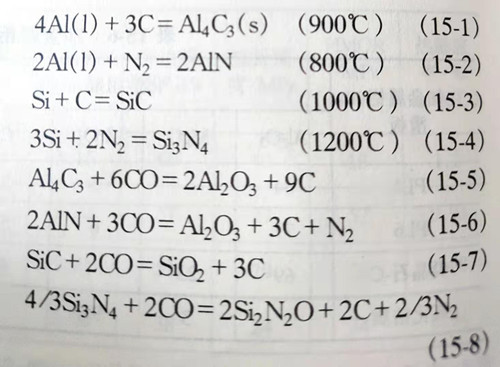

4) metal and non-oxide additives, their main role is to improve the oxidation resistance of aluminum carbon slide, but also to improve the strength of the role. Additives are metal and non - oxide, often used metal silicon powder, metal aluminum powder, silicon carbide, boron carbide and so on. Because of the reaction in the firing process, they have important influence on the performance and microstructure of the skateboard. In addition, the carbides or nitrides generated by the reaction of metal additives improve the oxidation resistance of the skateboard. The additives or the reaction products produced during the combustion of the skateboard are used before the graphite oxidation, which plays a role of delaying the graphite oxidation. The reactions of several additives in the fired and oxidized atmosphere are as follows:

At the same time, adding Al and Si, the formation temperature of non-oxide will be reduced. The effects of metal and non-oxide additives are as follows: the reaction product fills the void and reduces the porosity; The reaction products protect the carbon bonding and provide a certain degree of ceramic bonding, which is beneficial to improve the strength and increases with the increase of metal addition in a certain range. The inhibition of graphite oxidation can partly solve a series of destructive effects caused by graphite oxidation, such as the reduction of strength after carbon oxidation and the erosion resistance, and the increase of pores to infiltrate molten steel, which is prone to surface hair.

5) binder. Phenolic resin is generally used as binder. The phenolic resin binder has good wettability, good fluidity and high residual carbon content for corundum and graphite materials.

(2) forming. The forming of the slide board needs higher pressure to ensure that the blank body has high density, low porosity and high strength. According to the size of the slide board, it is formed by hydraulic press or friction brick press with a large enough tonnage.

(3) drying and firing. After the blank body is dried in the tunnel drying kiln, it is usually burned by burying carbon for protection. The firing temperature is generally 1300~1450℃.

(4) vacuum oil immersion and distillation. Vacuum oil immersion device is adopted to treat the skateboard after burning and conduct heat treatment. This process can improve the strength of the skateboard, reduce the porosity, prevent the skateboard from cracking, prevent the air intake of the sliding nozzle mechanism, and reduce the multiple effects of friction between the skateboards.